- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

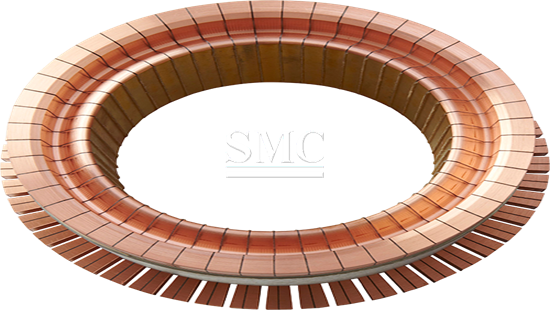

Commutator

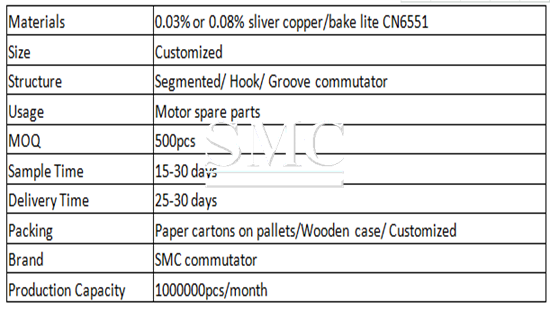

Materials: 0.03% or 0.08% sliver copper/bake lite CN6551

Size: Customized

Structure: Segmented/ Hook/ Groove commutator

Shanghai Metal Corporation is a leading Commutator manufacturer and supplier.

A commutator is a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the currentdirection between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature of the machine. Two or more electrical contacts called "brushes" made of a soft conductive material like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings (coils of wire) on the armatureare connected to the commutator segments.

Commutators are used in direct current (DC) machines: dynamos (DC generators) and many DC motors as well as universal motors. In a motor the commutator applies electric current to the windings. By reversing the current direction in the rotating windings each half turn, a steady rotating force (torque) is produced. In a generator the commutator picks off the current generated in the windings, reversing the direction of the current with each half turn, serving as a mechanical rectifier to convert the alternating current from the windings to unidirectional direct current in the external load circuit.

Commutators are relatively inefficient, and also require periodic maintenance such as brush replacement. Therefore, commutated machines are declining in use, being replaced by alternating current (AC) machines, and in recent years by brushless DC motors which use semiconductorswitches.

If you want to know more about our commutator or other copper electrical products price please feel free to contact us, we will reply you within 24 hours.

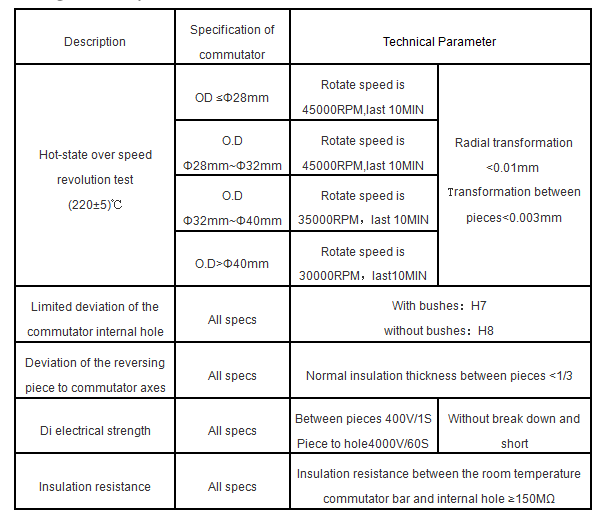

Testing technical parameter:

Commutator analysis drawing:

Packaging of Commutator:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

Application:

For auxiliary motors

For fuel pump motors

For starter motors

For E-motors/Alternators*

For household appliance motors

For industrial motors

For power tool motors

Advantages

Complete solution (development, production & support services)

Long tradition and experience in re-forming of copper and injection molding

Established development and quality processes according to quality standards

In-house manufacture of tools and production equipment for the automation process

Sustained level of quality at all production locations worldwide

Reliable partner ensuring optimal relation between quality and price

here

for

price