- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Anodized Aluminum Sheet

Gauge(Thickness): 0.3mm - 5mm

Width: up to 2000mm

Anodic layer: 2um -25um

Anodized aluminum sheet is to place the aluminum sheet in corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode for electrolysis under specific conditions with externally applied current. The aluminum sheet of the anode is oxidized and has an aluminum oxide film formed on the surface; the film is 5-20μm thick, and a hard anodic oxidation film can be up to 60-200μm thick. After anodization, the aluminum sheet achieves greater hardness, better abrasive resistance (up to 250-500 kg/mm2), and good resistance to heat; the hard anodic oxidation film also features a melting point of up to 2320 K, excellent insulation, high breakdown voltage (up to 2000V), and enhanced resistance to corrosion (it may stand salt spray under ω=0.03NaCl for thousands of hours without being corroded). Additionally, the oxide film is distributed with numerous pores that can absorb various lubricants, thus making the anodized aluminum sheet suitable for manufacturing engine cylinder or other wear-resistant parts; the strong absorbability of the film can also be well utilized to form various bright colors.

Specifications of Anodized Aluminum Sheet:

1) Gauge(Thickness): 0.3mm - 5mm

2) Width: up to 2000mm

3) Anodic layer: 2um -25um

4) A broad range of colours possible:

a) Clear anodizing: natural

b) Grey-Black

c) Champagne-Gold

d) Bronze

e) Stainless Steel

f) Blue

g) Red

Theoretically seen, any colour is possible with organic colouring

Features of Anodized Aluminum Sheet:

1) Light weight, 1/3 weight of stainless steel

2) Anti-scratch, the surface hardness reaches Sapphire Grade

3) Non-poisonous and environmental protection

4) Anti-static, anti-fingerprint, easy to clean

5) The surface anodized layer will never fade or fall off

Technical information of Anodized Aluminum Sheet:

1) Processing method: Anodization of aluminum sheet refers to the process of generating aluminum oxide film on the surface of an aluminum sheet through electrolysis when the aluminum sheet is put in the electrolyte as the anode.

2) Production flow chart:

Racking → Degreasing → Rinsing → Alkaline corrosion → Rinsing → Neutralizing → Rinsing → Anodizing → Rinsing → Pore sealing → Rinsing → Off rack → Testing → Packing

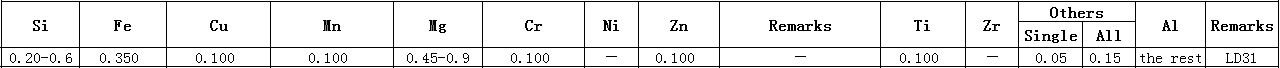

Chemical element:

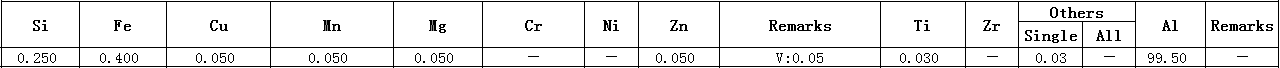

1050:

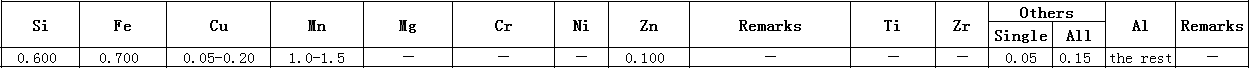

3003:

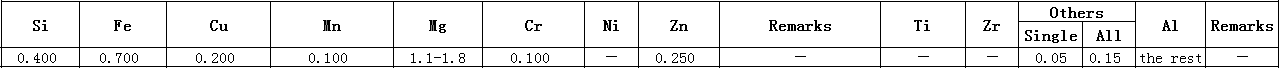

5005:

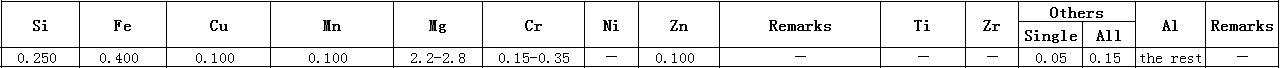

5052:

6063:

3.jpg)

Packaging of Anodized Aluminum Sheet

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Anodized Aluminum Sheet:

Anodised aluminum sheet is widely used and applicable to:

1) Metal aluminum ceiling

2) Curtain wall plate

3) Aluminum composite panel

4) Fireproof board

5) Honeycomb aluminum panel

6) Single aluminum sheet

7) Electric appliance panel

8) Cabinet panel

9) Furniture panel

Advantages of Anodized Aluminum Sheet :

1) Good process ability: the anodized aluminum sheet is strongly decorative, featuring moderate hardness and easy bending and shaping; it can be processed by continuous pressing at high speeds, and directly made into products without requiring complex surface treatment, thus having greatly reduced the production period and the production cost of products.

2) Good weather ability: an anodized aluminum sheet with oxide film of standard thickness (3μm) stands colorfast for a long time when it is used indoors, with no corrosion, oxidation or rusting; a thickened anodized aluminum sheet (thickness of 10μm) can be used outdoors with colorfastness under long-time exposure to sunlight.

3) Prominent metallic features: anodized aluminum sheets may have their hardness on a par with gems and are well resistant to scratches; they have no paint coating on the surface and thus have retained the metallic gloss of aluminum sheets, protruding the modern metallic features and promoting the class and added value of the products.

4) Good resistance to fire: as the anodized aluminum sheet is purely made of metal without any paint or chemical substance, it neither combusts at a temperature as high as 600 degrees, nor generates any poisonous gas, and thus satisfies the requirements for environmental protection.

5) Good resistance to dirt: the anodized aluminum sheet retains no finger print, and thus no stains will be left; it can also be easily cleaned, without producing any corroded spot.

6) Wide applicability: the anodized aluminum sheet is widely used, and applicable to metal aluminum ceiling, curtain wall plate, aluminum composite panel, fireproof board, honeycomb aluminum panel, single aluminum sheet, electric appliance panel, cabinet panel, furniture panel, etc.

here

for

price