- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Capillary Copper Tube/ Copper Capillary Tube for Refrigerators

Grade: C1100, C1020, C1220

Outside diameter: >=1.5mm

Thickness: >=0.45mm

Coil weight: 5kg, 10kg, 20kg, 50kg or not fixed weight per coil

Capillary copper pipe are critical parts used as restrictors against refrigerant flow and pressure in the refrigeration cycle of air conditions, electric refrigerators, showcases freezer, this copper tubing usually manufactured with fine precision, down to one thousandth of an inch. This precision allows airflow to be smoother, more uniform, and more closely monitored, making such applications as fluid & air restrictors much more useful. Capillary copper tubing has very small inside diameters

Main material: 99.99% copper

Specifications of Capillary Copper Tube (Copper Capillary Tube):

1) Grade: C1100, C1020, C1220

2) Outside diameter: >=1.5mm

3) Thickness: >=0.45mm

4) Coil weight: 5kg, 10kg, 20kg, 50kg or not fixed weight per coil

5) Production Standard: ASTM B280, ASTM B360, JISH3300, etc.

6) Copper tube Temper: Soft, half hard, hard

Package: Each end capped, enlanced by the foam bags and then put into the cartons

1) Small external diameter

2) High precision

3) Smooth internal and external surface

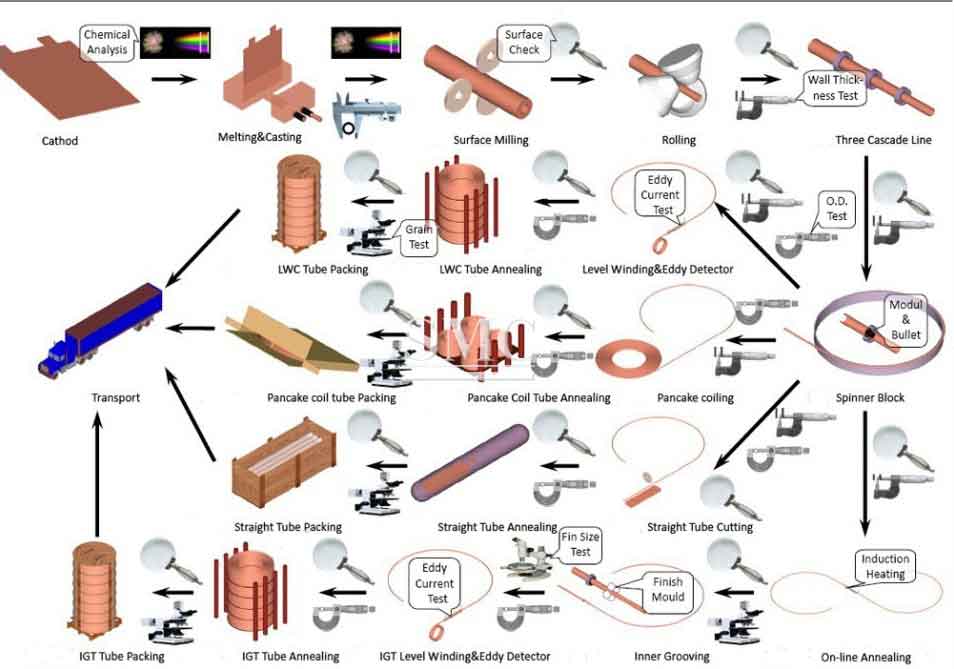

Manufacturing of Capillary Copper Tube

Packaging of Capillary Copper Tube

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Packing:

1) Seaworthy package

2) With plastic cap to protect both ends

3) Plastic bag wrapped outside the pipe

4) Bundles to be covered by polythene & strapped securely

5) If require, pack with wooden box

Inspection for Capillary Copper Tube:

1) Chemical Analysis

2) Component Analysis

3) Spectroscopic Analysis

4) Physical Property Inspection

5) Eddy Current Inspection

6) Ultrasonic Inspection

Mill Test Certificate is supplied with shipment

Third Part Inspection is acceptable

here

for

price