- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Finned Radiator For Transformer

Element width: 310mm, 480mm, 520mm, 535mm etc.

Element thickness: 1.0mm, 1.2mm etc.

Central distance: 500-4000mm

The high efficiency finned radiator’s cooling element is manufactured by automatic punching, combining, drop sew-welding and edge cutting

with high quality cold rolled steel sheets. We use outside CO2 protection welding to do the connection between elements and oil collection pipe.

This technique could avoid the welding residue or iron scrap produced by inner welding, which will affect the heat transfer performance and

quality of the radiator. Also the finned radiator will be strictly checked with sealing test and hot oil flushing, its surface with hot-dip galvanizing and

painting, to guarantee the product quality.

The finned radiator fully meets the transformer industry standard JB/T 5347 and BS-EN 50216-6 when tested by third-party inspection institute.

Specfication of Finned Radiator for Transformer:

Element width:310mm, 480mm, 520mm, 535mm etc.

Element thickness: 1.0mm,1.2mm etc.

Central distance:500-4000mm

Oil collection pipe:

88.9mm(3.5inch)x4mm, 114.3mm(4.5inch)x4.5mm

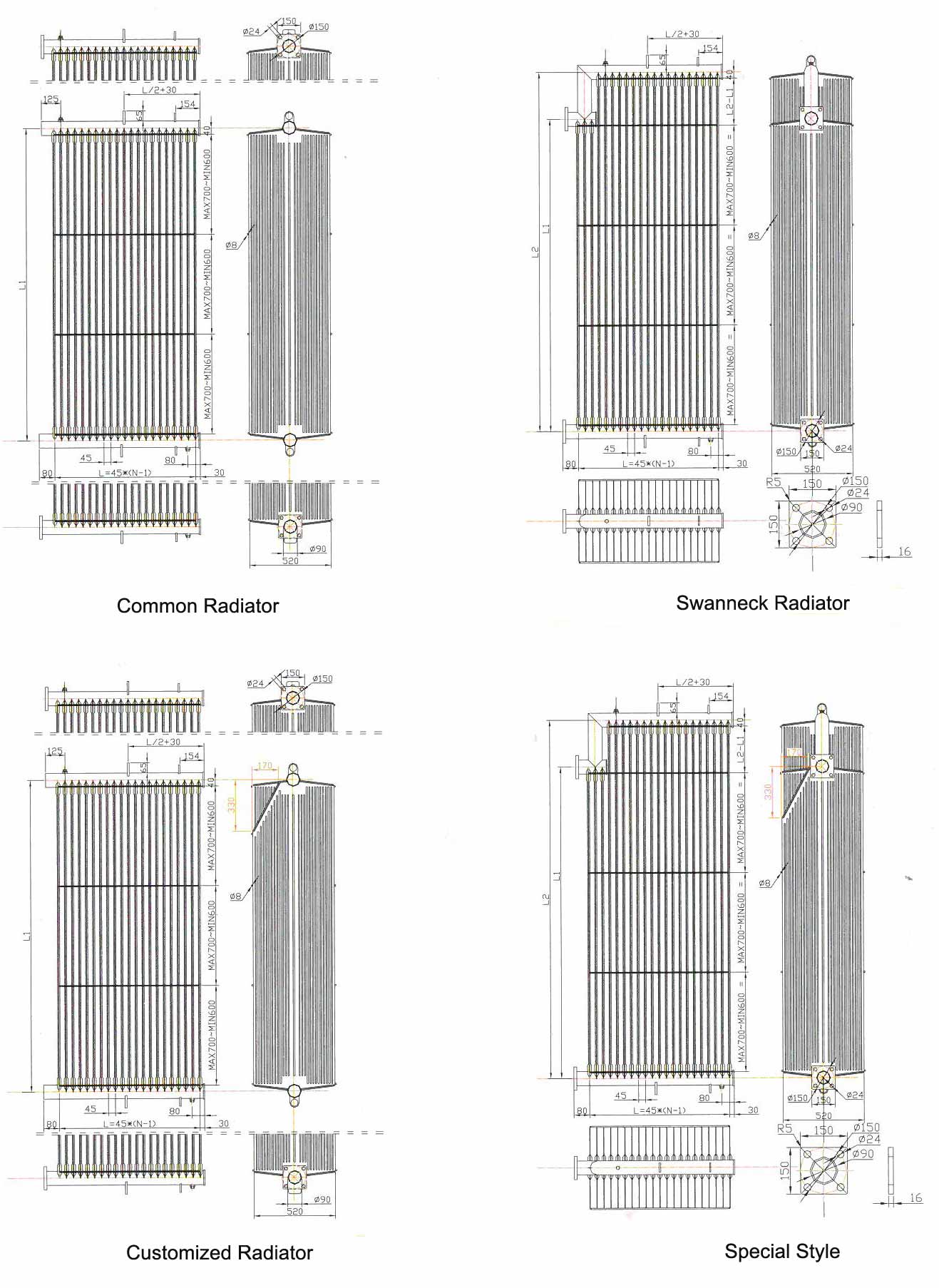

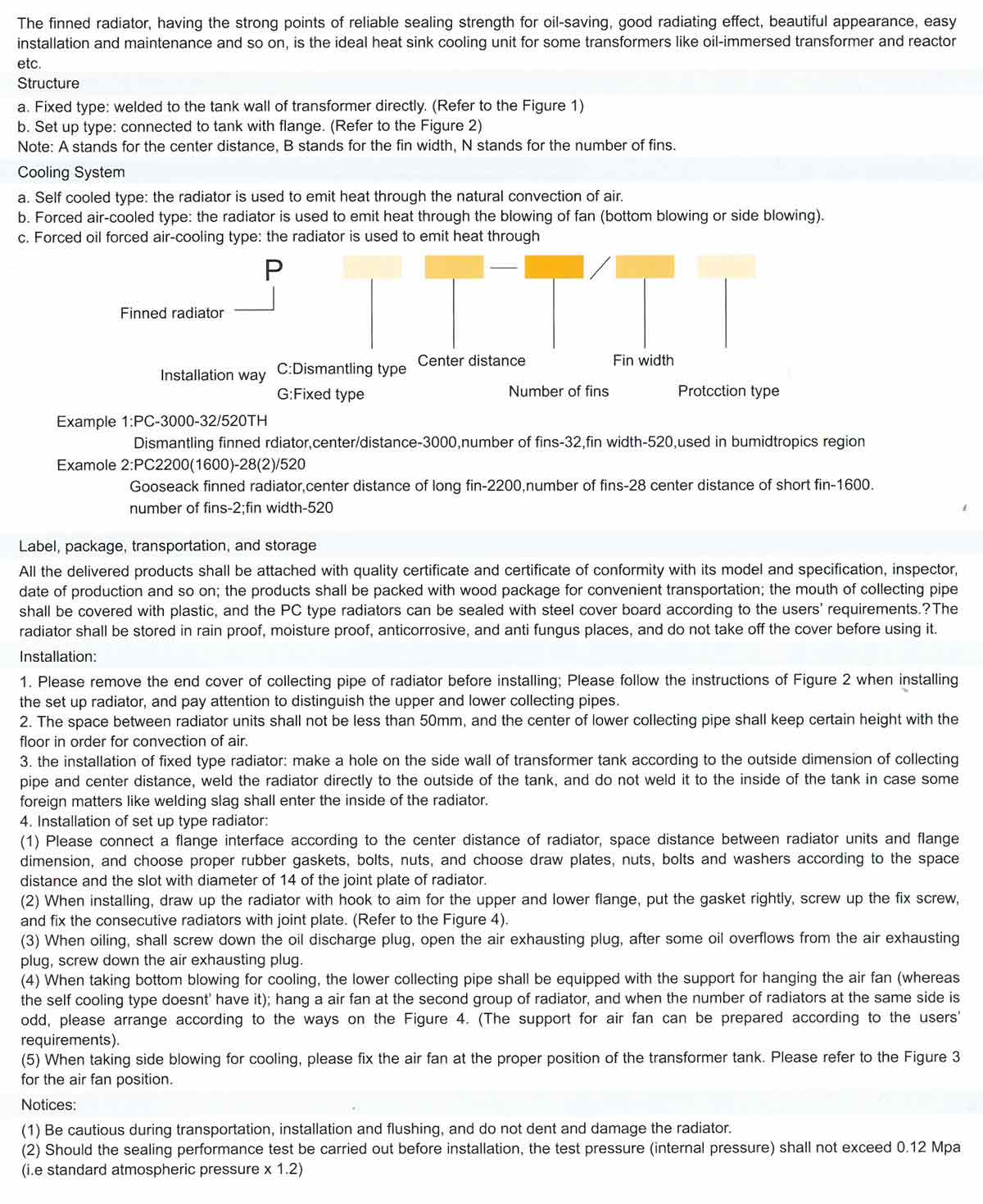

Structure type:

(1) fixed(PG type, without flange)

(2) demountable(PC type, connected with flange)

External surface: Hot-dip galvanized, powder coating

Radiator type:

Technical parameters for typical element widths:

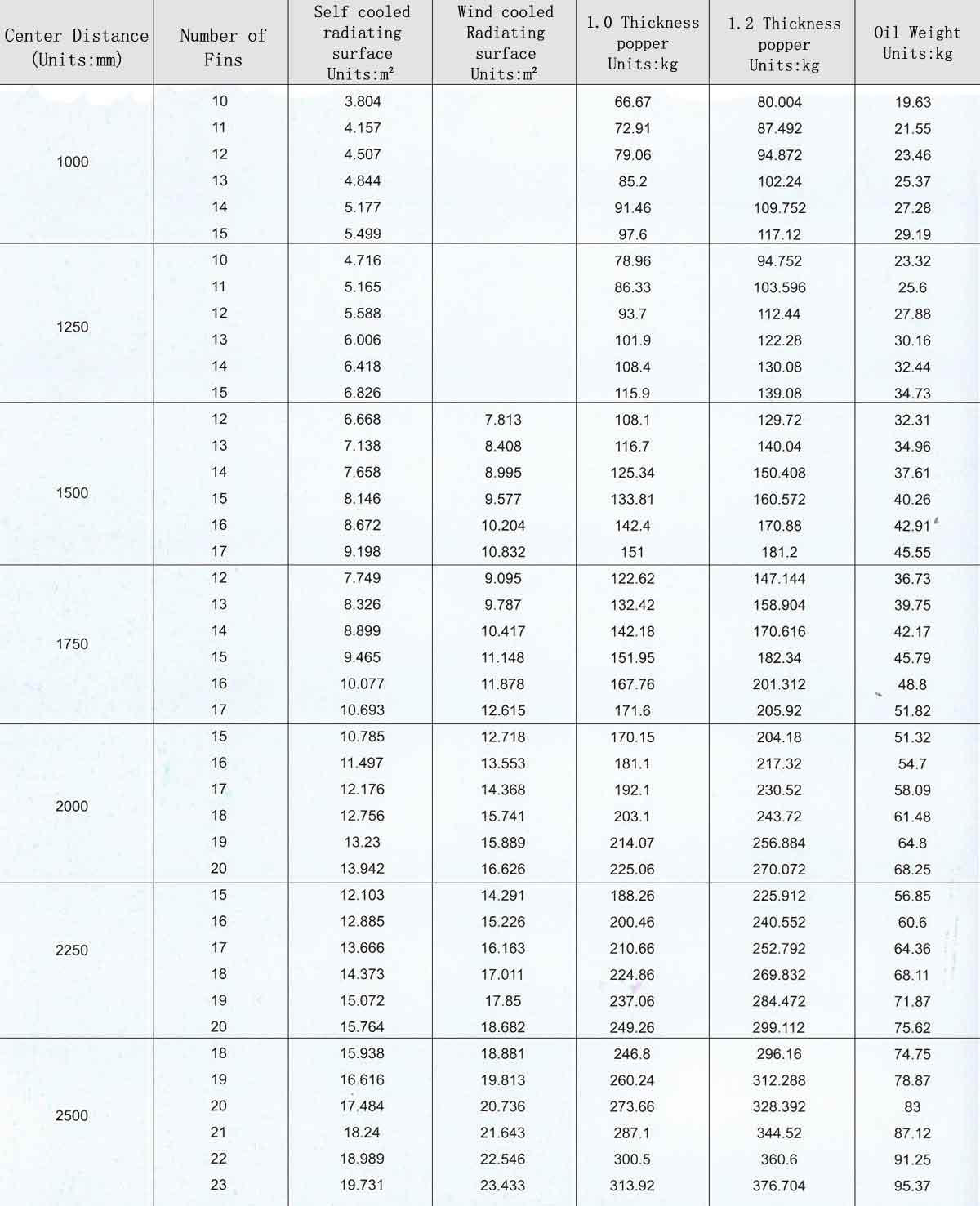

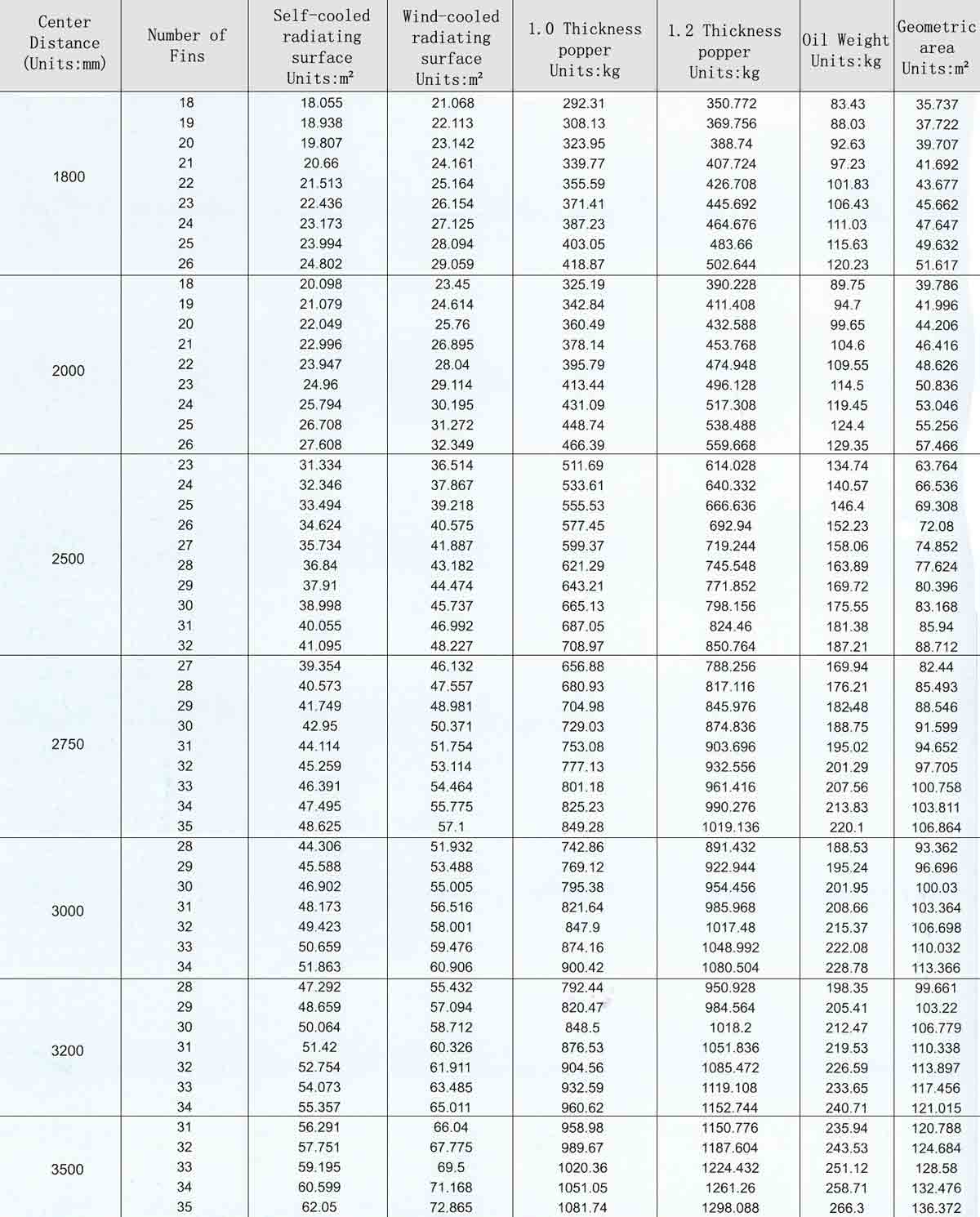

Parameters of 310mm plate type radiator:

Parameters of 480mm plate type radiator:

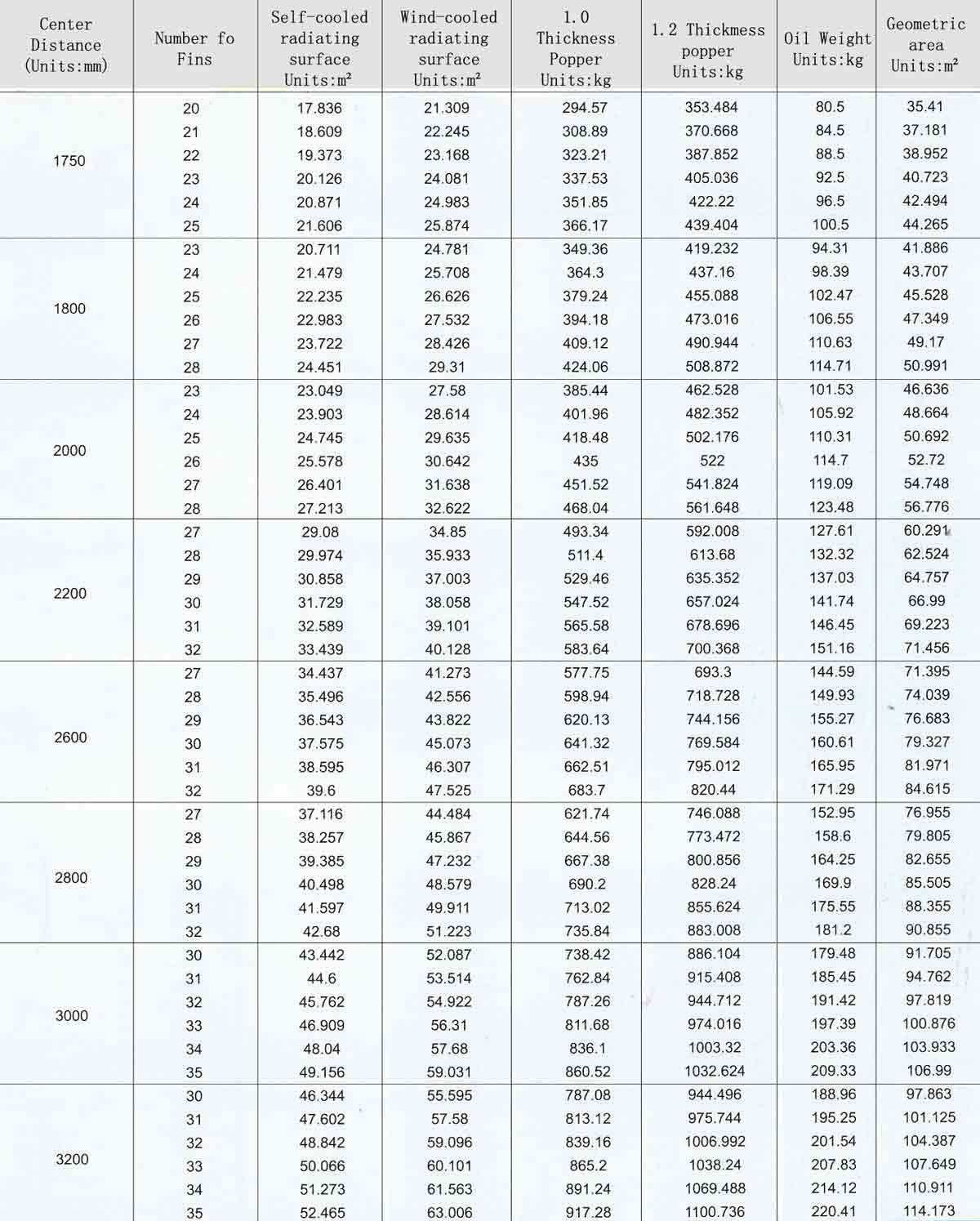

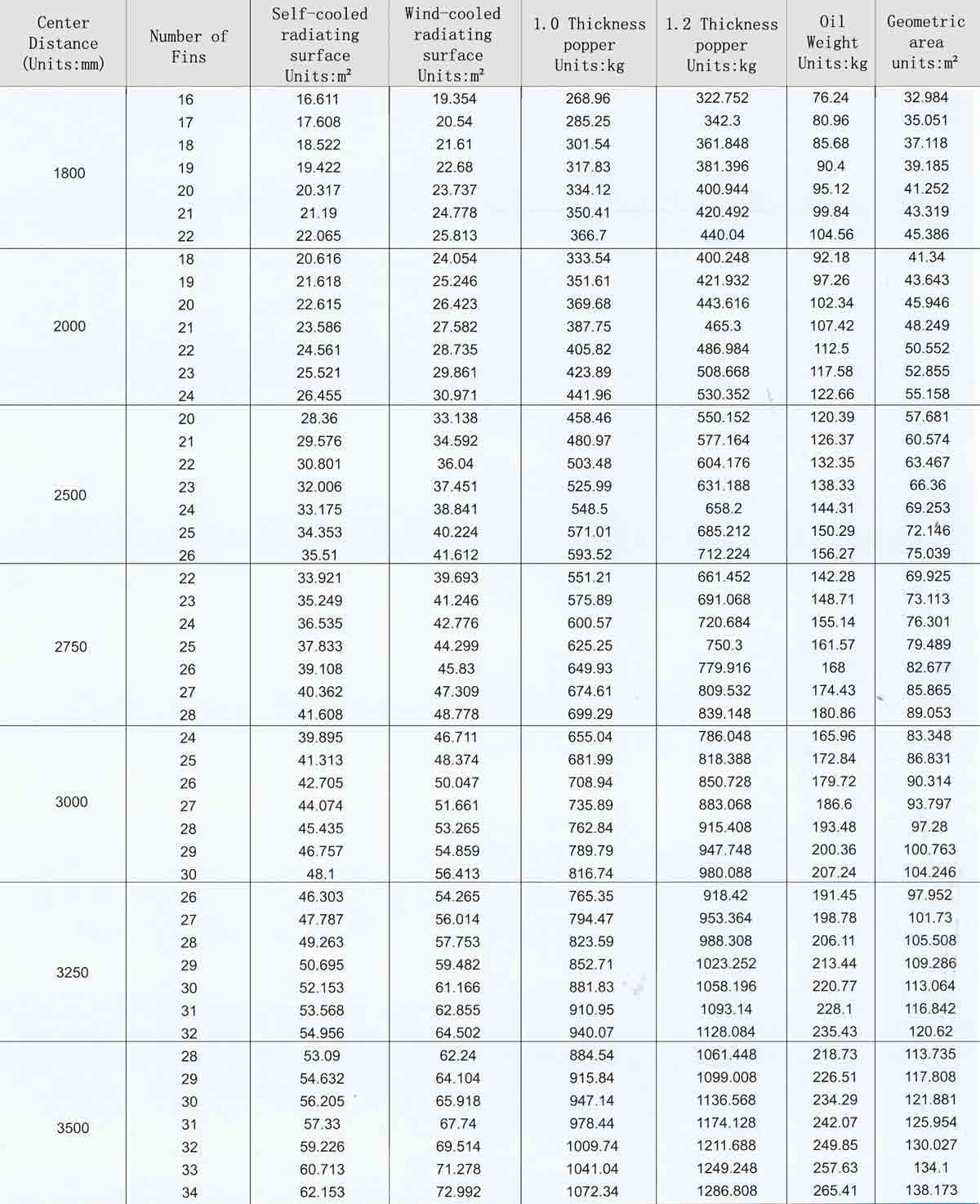

Parameters of 520mm plate type radiator:

Parameters of 535mm plate type radiator:

Instructions & Installation of Finned Radiator For Transformer:

here

for

price