- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Steel Pipe Making Machine

Outer diameter: 5 to 219mm

Wall thickness: 0.2 to 4.0mm

Introduction of Stainless Steel Pipe Making Machine:

Stainless steel pipe making machine is designed for manufacturing stainless steel straight welded pipe for metallurgy, construction, transportation, and machinery and vehicle industries. To be specific, the stainless steel pipe production line can produce round pipe, square and rectangular tube, as well as section steels through cold rolled forming and high frequency welding technology.

This pipe making machine adopts long steel strip as the material to manufacture steel pipes according to requested size by cold rolled forming and argon arc welding method.

-

Structure of Stainless Steel Pipe Making Machine:

1) Double Side Uncoiler

2) 3-Stage Roller Tube/Pipe Making machine

A. Forming

B. Welding

C. Sizing

-

3) Welding Seam Grinding

4) Auto Cutter Unit

5) Electric Control System Equipment

6) Forming Roller

7) Auto Unloading Platform

Production Flow Chart:

Unfolding strip → Branding →Forming →Welding →grinding →Sizing →Straightening → Length fixing →Cutting →Un loading.

First, the coil is set onto the uncoiler, and the steel belt is loosened and rolled into the storage cage, before being transported into the forming machine.

The steel belt is first flattened out, and is processed through rollers to squeeze it to the desired pipe diameter.

The machine then welds, straightens and cuts the pipe to the length set in the automated cut-off machine, and transports the finished pipe to the run out table, where quality inspection can be performed.

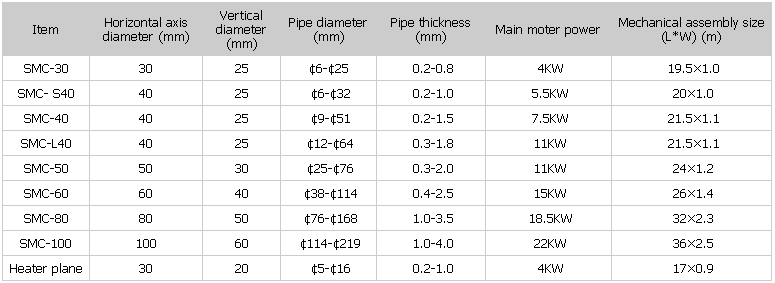

Technical Parameters of Stainless Steel Pipe Making Machine:

here

for

price