- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Tin Coated/Plated Copper Strip (Copper Strip Tin Coated) for Can Packaging

Base material thickness: 0.1mm - 0.8 mm

Reflow Tin Plating: Sn 0.8μm - 2.0μm

Base Material: Brass /Bronze /Copper /Lead Frame

Copper strips are tin plated and reflow-processed to improve their properties such as solderability, electric connectivity, and corrosion resistivity. These are highly reliable materials that were reflow processed after being tin-plated to prevent the generation of tin whiskers, which used to be a weakness of tin plating. Their press workability does not change after tin plating and they can be formed into complicated product shapes.

Specifications of Tin Plated Copper Strip:

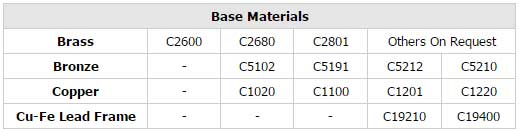

1) Grade

a) Brass: C2600, C2680, C2801

b) Bronze: C5102, C5191, C5212, C5210

c) Copper: C1020, C1100, C1201, C1220

d) Cu-Fe Lead Frame: C19210, C19400

2) Base Materials: Brass Bronze Copper Cu-Fe Lead Frame

3) Base material thickness: 0.1mm - 0.8mm

4) Width: Max. 300mm

5) Coil Weight: Max. 2400kg; Coil: 8kg/mm

6) Pre-plating: Cu: 0.4μm - 0.6μm

7) Reflow Tin Plating : Sn 0.8μm - 2.0μm

8) Standard: JIS H3100 Standard, Meets ROHS requierments

9) Chemical Composition:

Features of Tin Plated Copper Strip:

1) Eliminating detrimental "tin whisker"

2) Improving conductivity

3) Corrosion-resistance

4) Insertion force

5) Malleability for electrical connectors are additional benefits

Differences between Hot-dip Process and Reflow process:

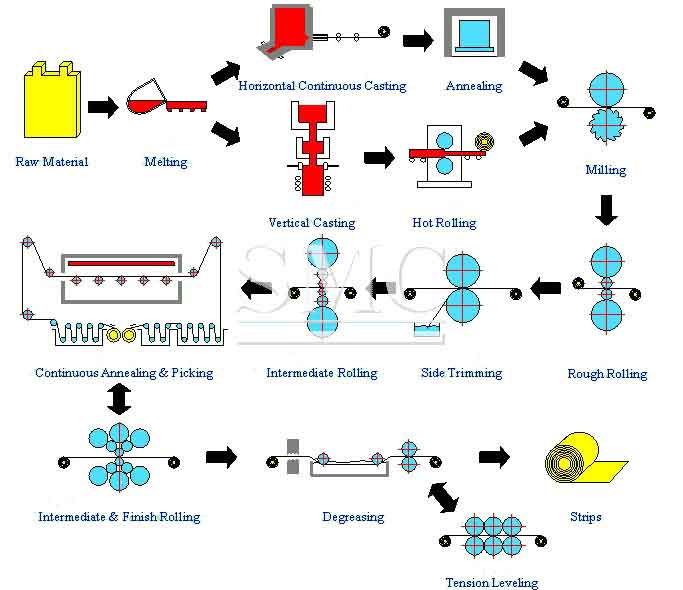

Manufacturing of Tin Plated Copper Strip

Packaging of Tin Plated Copper Strip

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Tin Plated Copper Strip:

1) Auto spare parts

2) Lead frames

3) Solar panel battery

4) Electronic devices for the telecommunications

5) Appliance

6) Connectors

7) Semiconductor

8) Electromagnetic shielding

here

for

price

.jpg)