- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

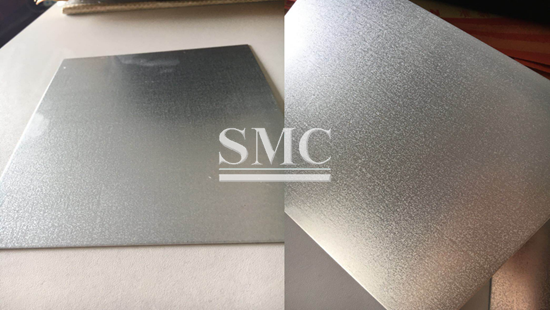

Magnesium Aluminum Zinc Alloy Coated Coil

Thickness: 0.27mm-2.0mm

Width: 1000mm-1250mm

Coating weight: ZM30-ZM275

Product description:

Magnesium Aluminum Zinc alloy coated sheet has excellent corrosion resistance, scratch resistance and good forming ability.

It can be applied in wide range of fields such as road/civil engineering, farming, construction, housing and others.

Shanghai Metal Corporation has succeeded to establish business relationship with clients in Europe and Southeast Asia.

It is chosen to be the newest coated steel material which is widely used in steel structure engineering, power engineering, solar power engineering, etc.

It is available in a very wide range of steel grades: steels for cold forming and deep drawing applications, structural steels and High Strength Low Alloy steels.

Standard:

1) ASTM A1046/A1046M

2) EN 10346

3) Company standard

Specification:

1) Thickness 0.27mm-2.0mm

2) Width 1000mm-1250mm

3) Surface:

- Surface quality: as coated(A), Improved(B), Best quality(C)

- Surface treatment: normal spangle, small spangle

- Surface finish: chromated no oiled

4) Coating weight: ZM30-ZM275

5) Dimensional deviation:

- Conform to EN 10143, ASTM A568

- Conform to company standard

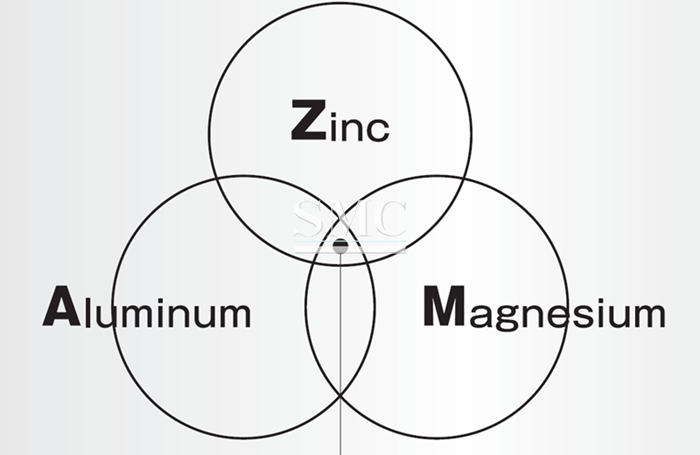

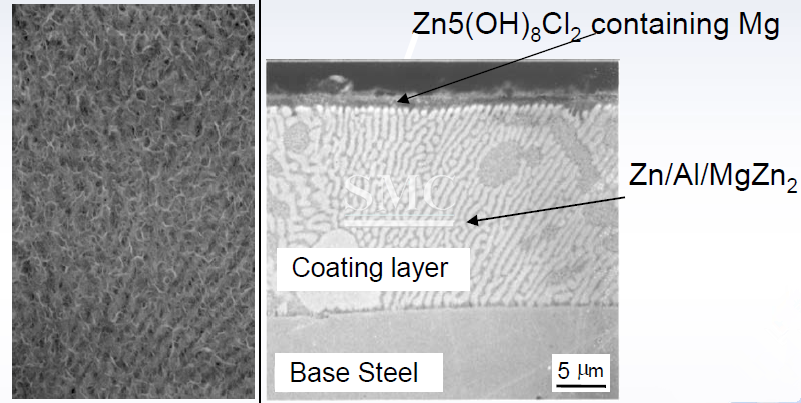

Composition of Coating

Mg-Al-Zn coated sheet is a highly corrosion-resistant hot-dipped coating steel sheet that has a coated layer of Zinc, 13% Aluminum, 3% Magnesium, and Silicon element.

Corrosion Mechanism

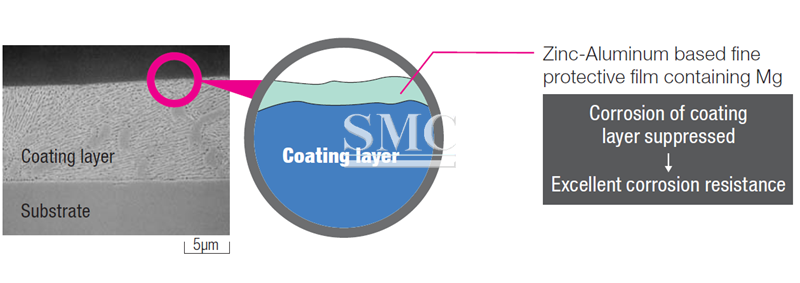

Al & Mg form a fine, tight protective film

Mechanism of corrosion resistance on flat surface

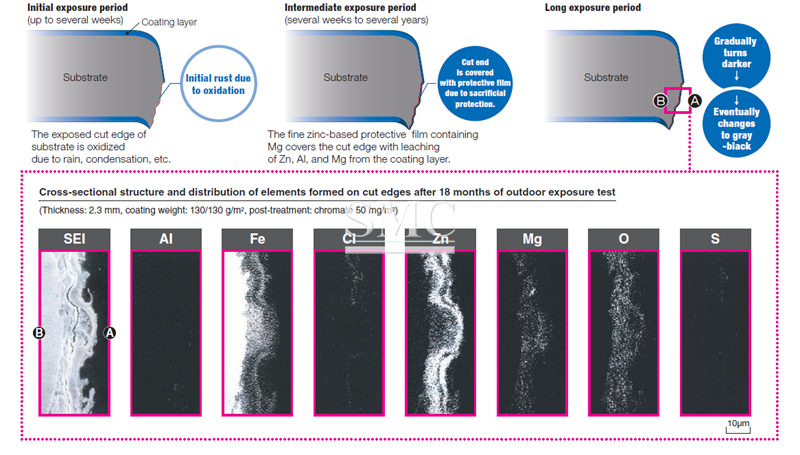

Mechanism of corrosion resistance on cut edge

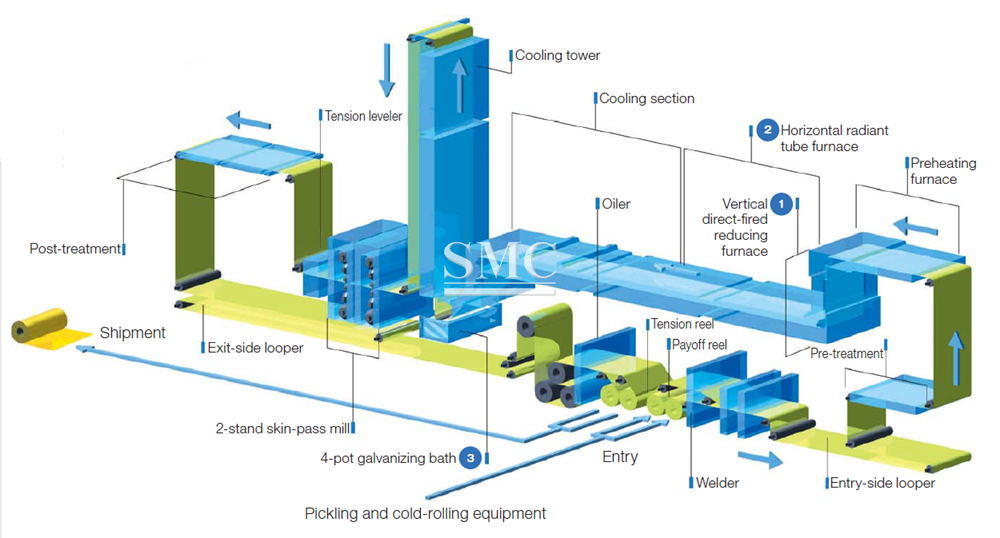

Manufacturing Process

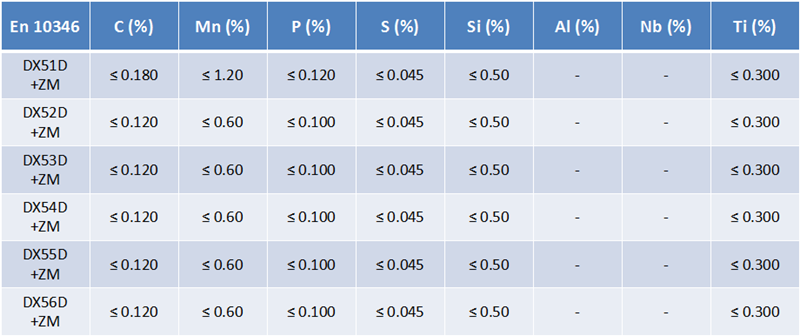

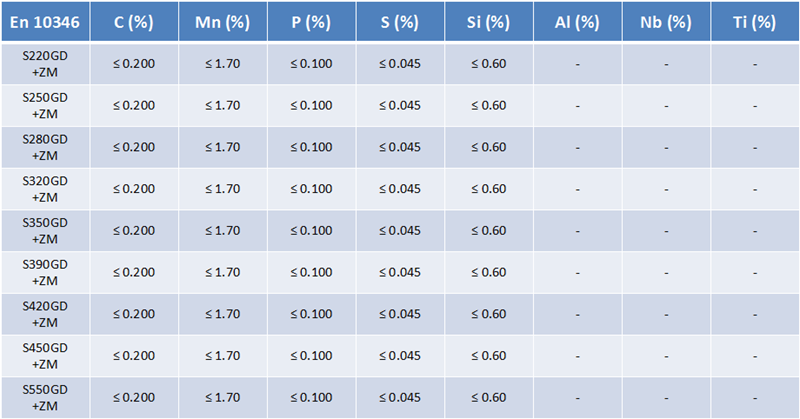

Chemical Composition

Steels for cold forming and deep drawing applications

Structural steels

Application

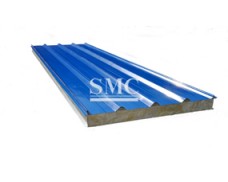

1) Construction: structural or non-structural profiles, roofing & cladding, decking, cable trays, expanded metal, gratings, composite flooring, concrete moulds

2) Road and railway infrastructure: safety barriers, protection equipment, sound insulation wall panels, walls providing protection against hail

3) Agriculture and farming: barns, greenhouse structures, agricultural equipment

4) Solar energy generation: structures for photovoltaic plants

5) Tubular applications: structural tubes for scaffolding, road signals, poles

Advantage

1) Excellent corrosion resistance on both surface and edge. 8-10 times of anticorrosion than GI

2) Excellent forming properties

3) Better welding ability than galvanized sheet and galvalume sheet

4) Less metallic coating with high anti-corrosion

5) Competitive price with high quality

here

for

price