- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

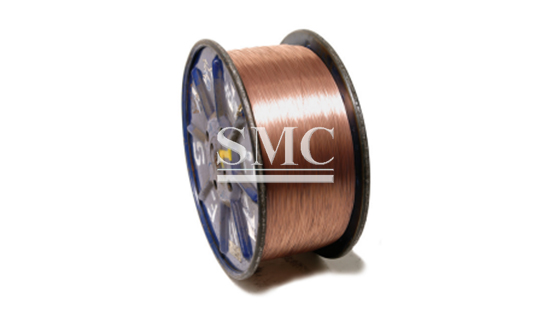

Bronze-Plated Steel Tire Bead Wire

Base Material: High carbon steel

Coating Material: Bronze

Standard: ASTM-D-1871 .ETC

Wire diameter: Ø1.55 mm~Ø1.65 mm and Ø0.78 mm~Ø0.96 mm

Shanghai Metal Corporation is a leading Bronze-Plated Steel Tire Bead Wire manufacturer and supplier.

The main reinforcing element of the bead part of tires is a bead ring made of steel wire coated with bronze to provide chemical bond with rubber. Bead wire contains of fiber stands disposed so as to provide both high strength and certain degree of flexibility needed for mounting and dismounting tires. Carcass layers are wrapped around the bead wire fixing carcass layers and holds the assembly on the wheel rim, thereby preventing the tire from rolling or sliding, providing road performance of the tire. Bead wire for bias and bias-belted tires is used on both sides of the tire. In cast tires bead wire is used for fixing the tire to the rim.

If you want to know more about our Bronze-Plated Steel Tire Bead Wire price please feel free to contact us, we will reply you within 24 hours.

|

Diameter(mm) |

Tolerance(mm) |

Tensile Strength Level |

Tensile Strength (Mpa) |

Breaking Force(N) |

Elongation(%) |

Torsion |

Yield Ratio(%) |

Straightness |

|

0.89 |

±0.02 |

NT |

≥1900 |

≥1180 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2150 |

≥1340 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

|

0.95 |

±0.02 |

NT |

≥1850 |

≥1310 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2100 |

≥1490 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

|

0.96 |

±0.02 |

NT |

≥1850 |

≥1340 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2100 |

≥1520 |

≥5.0% |

≥50(200d) |

85% |

≤600 |

|

|

1.00 |

±0.02 |

NT |

≥1850 |

≥1450 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2080 |

≥1630 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

|

1.20 |

±0.02 |

NT |

≥1800 |

≥2035 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2050 |

≥2320 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

|

1.26 |

±0.02 |

NT |

≥1790 |

≥2230 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2050 |

≥2555 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

|

1.30 |

±0.02 |

NT |

≥1790 |

≥2375 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2050 |

≥2720 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

|

1.42 |

±0.02 |

NT |

≥1785 |

≥2825 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2030 |

≥3210 |

≥5.0% |

≥22(100d) |

85% |

≤600 |

|

|

1.55 |

±0.02 |

NT |

≥1780 |

≥3360 |

≥5.0% |

≥20(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2015 |

≥3800 |

≥5.0% |

≥20(100d) |

85% |

≤600 |

|

|

1.60 |

±0.02 |

NT |

≥1780 |

≥3580 |

≥5.0% |

≥20(100d) |

85% |

≤600 |

|

±0.02 |

HT |

≥2010 |

≥4040 |

≥5.0% |

≥20(100d) |

85% |

≤600 |

|

|

1.65 |

±0.02 |

NT |

≥1780 |

≥3805 |

≥5.0% |

≥20(100d) |

85% |

≤600 |

|

1.83 |

±0.03 |

NT |

≥1770 |

≥4650 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

±0.03 |

HT |

≥2005 |

≥5270 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

|

2.00 |

±0.03 |

NT |

≥1680 |

≥5275 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

±0.03 |

HT |

≥1850 |

≥5810 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

|

2.03 |

±0.03 |

NT |

≥1680 |

≥5435 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

±0.03 |

HT |

≥1850 |

≥5985 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

|

2.20 |

±0.03 |

NT |

≥1630 |

≥6190 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

|

±0.03 |

HT |

≥1820 |

≥6915 |

≥5.0% |

≥16(100d) |

85% |

≤600 |

Package: Carton packed on the pallet, or according to customer’s requirement

here

for

price