- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Cold Rolled Steel Coil

Thickness: 0.18mm - 3.5mm

Width: 1000/ 1219/ 1250/ 1500/ 1800mm

Coil ID: 508mm/ 610mm

-

Classification

Specification

Typical grade

Standard

Automobile

Low carbon steel, deep drawing IF steel, high strength IF steel, high strength low alloy steel, dual phase steel, bake hardening steel, TRIP steel

DC01-DC06 CR220IF HC340LA 590DP 220P1 CR220BH CR420, STKM 11A

EN10130 EN10268 JIS G 3141 JIS G 3135 Q/TB303 Q/HG031

Home Appliance

Low carbon steel, IF steel, Al-killed steel

DC01-DC06 SPCC-J1 SPCC-J2 SPCD SPCE

Q/HG 009 EN10130 JISG3141 GB/T 5213 ASTMA1008M

Special Purpose

Flux cored welding wire slideway steel, steel sheet for security door chain steel

TYH THD SPCC-SC TLA

2016JX(027) JT010-2013 Commercial sheet Low carbon steel SPCC DC01 Q/HG006 EN10130 GB/T5213-2008

Commercial

Low carbon steel

SPCC DC01

Q/HG006 EN10130 GB/T5213-2008

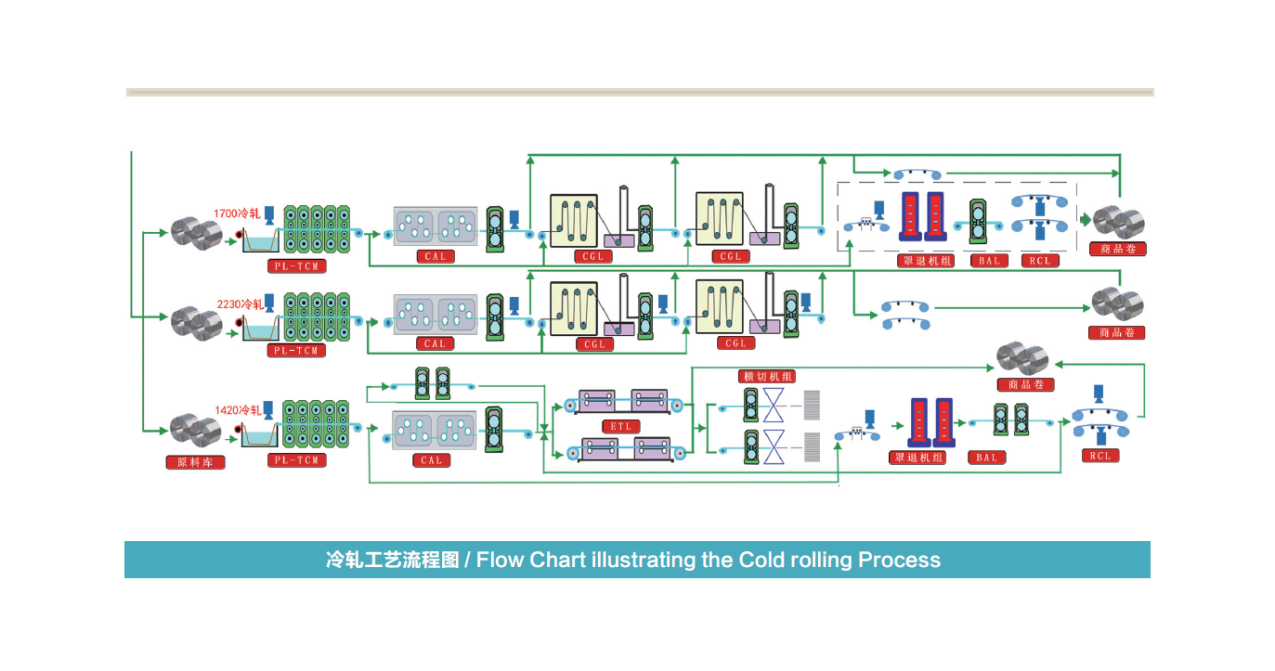

Production process of Cold Rolled Steel Coil:

Chemical Components:

|

Grade |

Chemical Components |

||||

|

c |

Mn |

P |

S |

Alt |

|

|

SPCC |

≤0.12 |

≤0.50 |

≤0.035 |

≤0.025 |

≥0.020 |

|

SPCD |

≤0.10 |

≤0.45 |

≤0.030 |

≤0.025 |

≥0.020 |

|

SPCE |

≤0.08 |

≤0.40 |

≤0.025 |

≤0.020 |

≥0.020 |

Mechanical Properties:

|

Grade |

Strength |

||||

|

YS |

TS |

Elongation(%) |

|||

|

MPA |

δ |

S |

P |

||

|

SPCC DC01 |

130-260 |

270-410 |

28 |

|

|

|

SPCD DC03 |

120-240 |

270-390 |

34 |

|

|

|

SPCE SPCEN |

<210 |

270-370 |

38 |

|

|

|

DC04 DC05 |

<210 |

270-370 |

38 |

|

|

|

AISI1006 |

275-365 |

275-380 |

34 |

32 |

30 |

|

AISI 1008 |

275-390 |

275-410 |

32 |

30 |

28 |

|

AISI 1010 |

295-410 |

295-430 |

30 |

29 |

28 |

|

AISI 1020 |

355-490 |

355-500 |

26 |

25 |

24 |

|

AISI 1045 |

|

530-685 |

|

|

16 |

|

AISI 1050 |

|

540-715 |

|

|

14 |

|

AISI 1060 |

|

550-775 |

|

|

12 |

|

ST33 S185JR |

185-195 |

315-430 |

33 |

|

|

|

ST37 S235JR |

215-235 |

375-500 |

25 |

|

|

|

ST37 S355JR |

275-325 |

510-680 |

18 |

|

|

Thickness Tolerance:

|

Thickness (mm) |

Tolerance allowed(min) |

|

0.20-0.50 |

+/-0.05 |

|

0.50-0.65 |

+/-0.06 |

|

0.65-0.90 |

+/-0.07 |

|

0.90-1.00 |

+/-0.09 |

|

1.10-1.20 |

+/-0.10 |

|

1.20-1.40 |

+/-0.12 |

|

1.40-1.50 |

+/-0.13 |

|

1.50-1.80 |

+/-0.14 |

|

1.80-2.00 |

+/-0.15 |

|

2.50-3.00 |

+/-0.20 |

Width Tolerance:

|

Width(mm) |

Tolerance allowed (mm) |

|

≤200 |

+2.0/-1.0 |

|

>200-300 |

+2.5/-1.0 |

|

300-400 |

+3.0/-2.0 |

|

400-600 |

+3.5/-2.5 |

|

600-1000 |

+6/-0 |

|

>1000 |

+10/-0 |

Reference list of supply standards and steel grades as well as those equivalent or close to them:

|

Standard No. |

Q/BQB 418-2003 |

JFS A2001-1998 |

Q/BQB 418-1999 |

|

Steel Grade |

B340/590DP |

JSC590Y |

B340VK |

|

B400/780DP |

JSC780Y |

B400VK |

Mechanical performances:

|

Steel Grade |

Yield Strength |

Tensile |

Elongation(Lo=50mm) |

180°Bending Test |

||

|

Nominal Thickness mm |

||||||

|

0.60~<1.0 |

1.0~<1.6 |

1.6 |

Bending Center Diameter |

|||

|

B340/590DP |

340-500 |

590 |

16 |

18 |

20 |

0.5a |

|

B400/780DP |

400-590 |

780 |

- |

14 |

16 |

1.0a |

Surface quality:

|

Grade |

Code No |

Features |

|

Relatively high-grade finishing surface |

FB(O3) |

It is allowed for the existence of a few surface defects which will not affect forming and coating & plating adhesiveness such as minor scratch, impression, pit, roll mark and oxidation tint. |

|

High-grade finishing surface |

FC(O4) |

One side of relatively good quality is free from any remarkable defect visible and the other side must reach FB requirements at least. |

Packaging of Cold Rolled Steel Coil:

Products of Shanghai Metal Corporation are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

here

for

price