- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Cross-Linked Polyethylene (XLPE)

Chemical Formula: (C₂H₄)n

Cross-Linking Degree: Adjustable

Heat Resistance Range: -40°C to 90°C (long-term)

Compressive Strength: High

Cross-linked polyethylene (XLPE) is a modified form of polyethylene (PE), achieved through a cross-linking process that improves its material properties. By using high-energy radiation (such as gamma rays or electron beams) or cross-linking agents, polyethylene’s molecular chains are interconnected into a three-dimensional network, resulting in significant enhancements in its mechanical strength, chemical resistance, creep resistance, electrical properties, and heat tolerance. XLPE’s heat resistance is especially notable, as it increases the material’s thermal stability from 70°C to over 100°C, expanding its range of applications significantly.

XLPE is widely used in electrical cables, pipes, films, and foam products, offering excellent durability and performance in various industries. In summary, cross-linked polyethylene (XLPE) represents a significant advancement in polymer materials, offering a perfect blend of enhanced mechanical properties, superior heat resistance, and excellent chemical stability. This innovative material is ideal for a wide range of applications, including electrical cables, pipes, and foamed plastics, providing long-lasting performance in demanding environments. Whether you're looking to improve the durability of your products or require advanced heat-resistant solutions, XLPE is an outstanding choice.

If you are interested in incorporating XLPE into your projects, please feel free to contact us. Our team is ready to assist you with any inquiries and provide timely support within 24 hours. For any questions or specific needs regarding XLPE, don’t hesitate to reach out. We are dedicated to offering customized solutions to meet your unique requirements and help you achieve the best results in your applications.

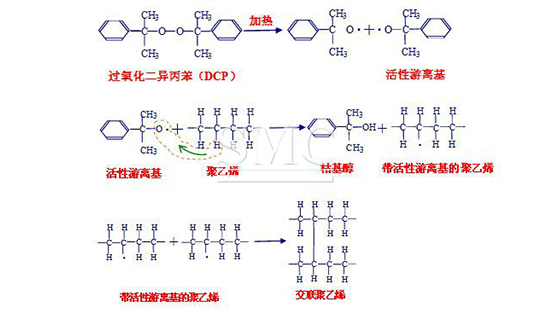

(1) Cross-Linking Principle:

Polyethylene (PE) is a polymer composed of linear molecular chains. When heated, the intermolecular forces weaken, causing the material to deform, which limits its heat resistance. Cross-linking polyethylene forms chemical bonds between the molecules, creating a three-dimensional network structure that prevents molecular displacement and significantly improves its heat resistance and mechanical properties.

Cross-linking can be achieved through physical methods (such as radiation) or chemical methods, with common techniques including high-energy irradiation, peroxide cross-linking, and silane cross-linking.

(2) Cross-Linking Methods:

-IXPE Physical Cross-Linking (Radiation Cross-Linking): This method involves irradiating polyethylene products (such as wire coatings, films, and thin-walled pipes) with gamma rays or high-energy electrons. The radiation creates free radicals in the polymer chain, initiating cross-linking. This method is beneficial for controlling the cross-linking degree and ensuring high-quality production.

- XPE Chemical Cross-Linking (Peroxide Cross-Linking): This technique uses peroxides to generate free radicals through thermal decomposition, which then triggers the cross-linking reaction, forming a network structure. This method is commonly used in medium-to-high voltage cable production, where enhanced mechanical and electrical properties are required.

- Silane Cross-Linking: Silane cross-linking uses vinyl silane compounds to react with molten polyethylene, creating a silane-grafted polymer. The polymer then undergoes a water-induced hydrolysis reaction that results in a cross-linked structure. This method is cost-effective, easy to control, and produces high-quality, durable products.

here

for

price