- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

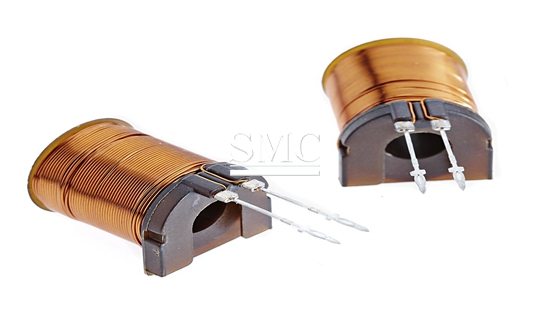

Enameled copper Wire/ Ultra Fine Rectangular Enameled Copper Wire

Shanghai Metal Corporation is a leading enameled copper wire manufacturer and supplier.

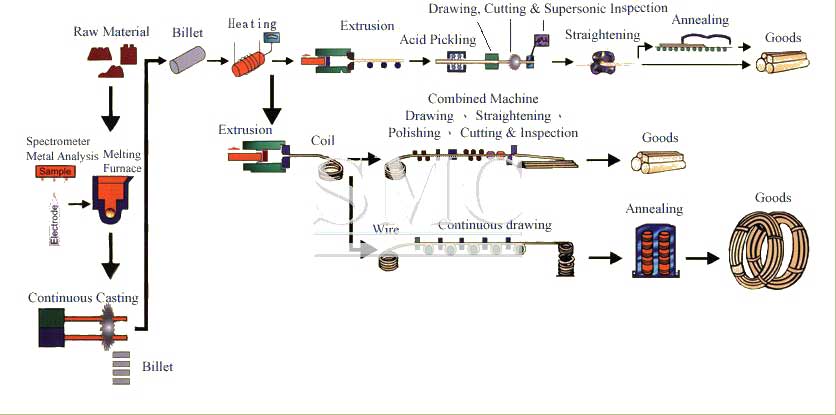

Enamelled wire is a main kind of winding wire. It consists of conductor and insulating layer. After annealing and softening, the bare wire is painted and baked many times. However, it is not easy to produce products that meet both standard requirements and customer requirements. It is affected by raw material quality, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have mechanical, chemical, electrical and thermal properties.

Enamelled wire is the main raw material of electrical machinery, electrical appliances and household appliances. Especially in recent years, the electric power industry has achieved sustained and rapid growth, and the rapid development of household appliances has brought a broader field to the application of enameled wire. Accordingly, higher requirements have been put forward for enameled wire.

If you want to know more about our Enamelled Copper Wire or other copper wire price please feel free to contact us, we will reply you within 24 hours.

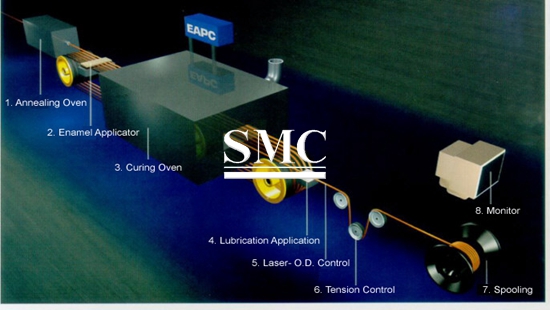

Facility of Round Enameled Copper Wire:

Shanghai Metal Corporation has taken the lead in importing the Enameled Copper Wire production and inspection equipment of the advanced international standards. The annual output of Enameled Copper Wire over 7,000 tons.

Manufacturing of Enameled Wire

Packaging of Enameled Wire

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Enameled Wire:

1) 120 degree flat enameled wire for oil-immersed transformer

2) 130,155,180 degree flate enameled wire are widely used in all kinds of magnet coil

3) 200 degree flat enameled wire works constantly in high temperature

4) 240 degree flat enameled wire for magnet coils of aviation, military and marine application

here

for

price