- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Galvalume Roofing Sheet for Roofing

Thickness: 0.15mm - 0.8mm

Standard: JIS3321/ASTM A792M

Aluminum-zinc Coating: 40g/m2 - 275g/m2

Galvalume Roofing Sheet is a flat carbon steel product coated on both sides with an aluminium-zinc alloy. The coating is composed of 55% aluminium, 43.4% zinc and 1.6% silicon and applied by means of a continuous hot dip galvanising process. Galvalume Sheet is available in a wide range of steel grades: steels for cold forming and deep drawing applications, and structural steels.

The excellent corrosion resistance of Galvalume Sheet is a result of the properties of its two metallic constituents: the barrier effect of the aluminium present on the surface of the coating and the sacrificial protection of zinc.

The characteristic spangled silver colour of Galvalume Sheet gives it a very attractive appearance. Thanks to a thin transparent layer of aluminium oxide on the top surface of the coating, this appearance is preserved over time.

Specifications of Galvalume Roofing Sheet:

1) Chemical Composition: 55% Aluminum, 43.4% Zinc, 1.6% Silicon

2) Substrate: Galvalume steel sheet & Pre-painted galvalume steel sheet

3) Standard: JIS3321/ASTM A792M

4) Alu-zinc Coating: 40g/m2 - 275g/m2

5) Galvalume Steel Thickness: 0.15mm - 0.8mm, all available

6) Prepainted Galvalume Steel Thickness: 0.16mm - 0.8mm, all available

7) Aluminum Coating: AZ50/AZ100/AZ150/AZ185

8) Spangle: regular spangle, minimized spangle, zero spangle

9) Surface treatment: Chemical treatment, oil, dry, anti-finger print

10) Features: long-term resistance to atmospheric corrosion, bright surface, paintability, durability and versatility

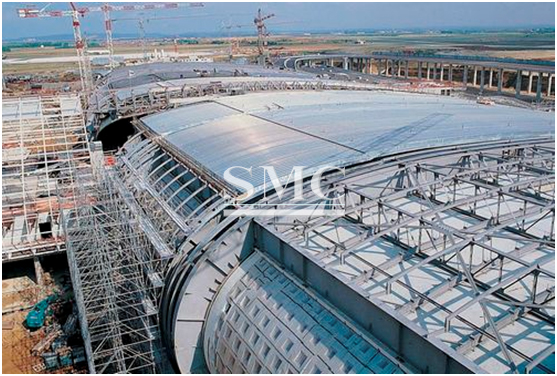

11) Applications: It is used as the wall or roofing of factories, warehouses, garages, exhibition centers, cinemas, etc.

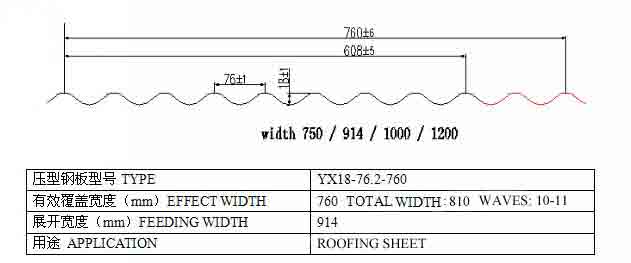

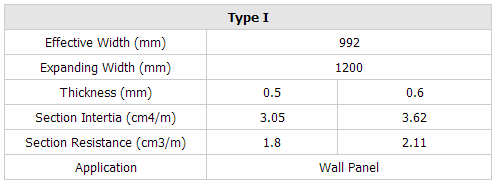

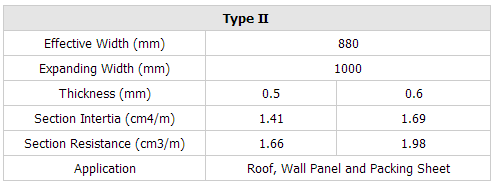

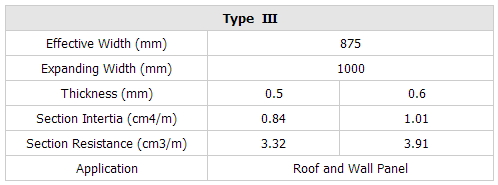

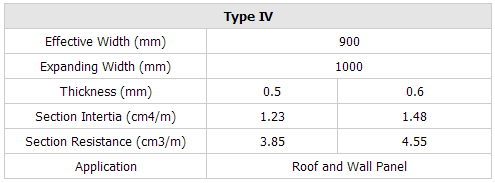

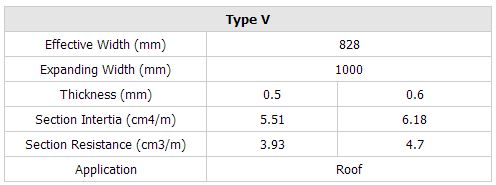

Types of Galvalume Roofing Sheet:

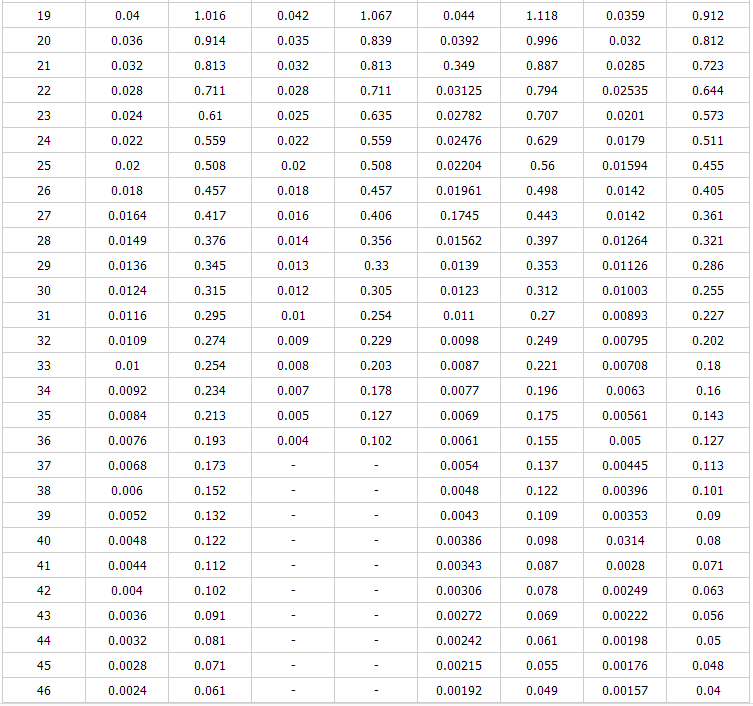

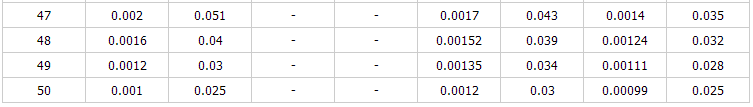

SMC Standard Sheet Metal Gauge:

Forming and joining

The forming and joining techniques currently used for uncoated steel sheets are also suitable for Galvalume Roofing Sheet.

The coating thickness must therefore be compatible with both the desired degree of corrosion protection and the requirements of the forming and welding processes envisaged. Forming performance is improved if Galvalume Roofing Sheet is coated with an thin organic coating.

Painting

Galvalume Sheet can be painted after degreasing and surface treatment when delivered oiled. Galvalume Sheet coated with an thin organic coating can be painted directly, without any prior surface treatment. However, the paint must be compatible with the resin.

Weldability

In electrical resistance welding, the welding current must be suitably regulated and regularly adjusted. Electrode life can be extended by regularly stepping up the welding current and periodically dressing (machining) the electrodes.

Coating weight and typical thickness

Packaging of Galvalume Roofing Sheet

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Storage and shipping

Galvalume Roofing Sheet is supplied passivated or oiled to temporarily limit any risk of black rust formation. During transport and storage, all necessary precautions must be taken to keep the material dry and to prevent the formation of condensation.

Applications of Galvalume Sheet:

Galvalume Sheet coated steels are used widely in both indoor and outdoor:

1) Construction: roofing, cladding, structural sections, composite panels, tiles, etc.

2) Appliances: washing machines, tumble dryers, refrigerators, toasters, microwave ovens, etc.

3) Miscellaneous: boiler casings, air ducts, electrical cabinets, lighting, computer casings, etc.

Features of Galvalume Roofing Sheet:

1) Good corrosion resistance at high temperatures

2) Good abrasion resistance because of its surface hardness

3) Excellent thermal and light reflectivity

4) Galvalume Roofing Sheet can be supplied oiled and/or with a chemical surface treatment, or with an thin organic coating

here

for

price