- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

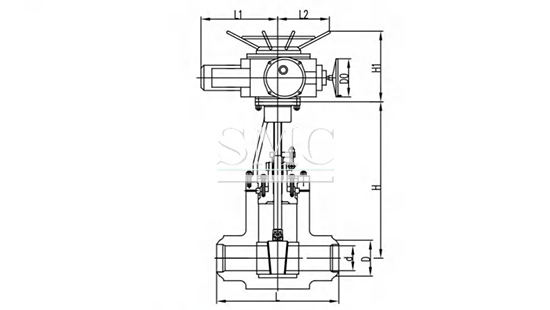

Gate Valve

Material: Carbon steel, Stainless steel, Alloy steel

Size: DN15-DN1000

Suitable medium: Water, Steam, and Oil products

Shanghai Metal Corporation is a professional manufacturer and supplier of Gate Valve with high quality and reasonable price.

The main function of a gate valve is to cut off the flow of the medium inside the pipeline. In the pipeline system, when it is necessary to inspect, maintain or replace equipment on a certain section of the pipeline, the gate valve can be closed to isolate the pipeline from other parts and ensure operational safety. In some special pipeline systems, gate valves can also be used in conjunction with check valves to prevent medium back flow. When the medium in the pipeline tends to flow back, the gate valve can be closed in time to prevent the medium from flowing back and protect the safety of equipment and pipeline systems.

If you want to know more about Gate Valve price please feel free to contact us, we will reply you within 24 hours

Technical Information of Gate Valve:

|

DN |

Z960Y-200 A105 |

||||||||||

|

d(mm) |

D(mm) |

L(mm) |

H(mm) |

H1(mm) |

DO(mm) |

L1(mm) |

L2(mm) |

配管piping |

电动装置 |

装置kg |

|

|

175 |

163 |

223 |

500 |

800 |

350 |

305 |

529 |

410 |

219x16 |

SMC-0 |

650 |

|

200 |

184 |

250 |

550 |

936 |

400 |

305 |

623 |

429 |

245×18 |

SMC-1 |

820 |

|

250 |

230 |

330 |

650 |

1170 |

450 |

458 |

697 |

457 |

325×25 |

SMC-2 |

1268 |

|

275 |

251 |

362 |

650 |

1266 |

610 |

458 |

697 |

47 |

356x26 |

SMC-2 |

1309 |

|

300 |

273 |

383 |

750 |

1460 |

500 |

610 |

838 |

540 |

377x28 |

SMC-3 |

2186 |

|

350 |

300 |

433 |

800 |

1630 |

600 |

610 |

923 |

565 |

426x30 |

SMC-4 |

3086 |

|

400 |

343 |

487 |

850 |

1810 |

650 |

610 |

923 |

565 |

480x35 |

SMC-4 |

4036 |

|

450 |

385 |

538 |

850 |

1916 |

1000 |

760 |

807 |

955 |

530x40 |

SMC-5 |

5426 |

|

Z960Y-250 A105 |

|||||||||||

|

125 |

111 |

172 |

400 |

612 |

350 |

305 |

529 |

410 |

168×16 |

SMC-0 |

430 |

|

150 |

136 |

198 |

500 |

750 |

400 |

305 |

623 |

429 |

194x20 |

SMC-1 |

610 |

|

175 |

157 |

223 |

500 |

838 |

400 |

305 |

623 |

429 |

219×22 |

SMC-1 |

782 |

|

200 |

178 |

250 |

550 |

946 |

450 |

458 |

697 |

457 |

245×25 |

SMC-2 |

880 |

|

225 |

200 |

278 |

550 |

1030 |

450 |

458 |

697 |

457 |

273×28 |

SMC-2 |

1030 |

|

250 |

222 |

330 |

650 |

1252 |

500 |

610 |

838 |

540 |

325×32 |

SMC-3 |

1780 |

|

300 |

263 |

383 |

750 |

1556 |

600 |

610 |

923 |

565 |

377x36 |

SMC-4 |

3208 |

|

350 |

289 |

433 |

800 |

1781 |

650 |

610 |

923 |

565 |

426×40 |

SMC-4 |

4737 |

|

400 |

330 |

487 |

850 |

1936 |

650 |

760 |

807 |

565 |

480×45 |

SMC-5 |

6488 |

Packaging of Gate Valve:

Products of Shanghai Metal Corporation are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

NOTICE:

1. Storage and installation: Gate valves should be stored in a dry warehouse and are strictly prohibited from being stored outdoors. When stored for a long time, regular inspections should be carried out, and the surface dirt should be removed and the rust inhibitor replaced every 6 months. During installation, the gate valve should be installed on a horizontal pipeline, with the driving device facing upwards and the valve stem perpendicular to the medium pipeline. Before installation, the pipes, valve chambers, sealing surfaces, and all exposed surfaces of the transmission pair should be cleaned of dirt and mud, and ensure that all bolts are evenly tightened.

2. Precautions for use: Gate valves cannot be used as regulating valves and can only be in the fully open or fully closed state. Otherwise, the sealing surface will be subject to erosion and mechanical wear by the medium, resulting in compromised tightness. When opening and closing gate valves, the force should be stable and even, and impact force should not be used. Under high pressure difference, the gate valve is prone to damage in a semi open and semi closed state, so it cannot be used for throttling or regulation and must be fully opened or fully closed at once.

3. Maintenance and upkeep: Regular inspection and maintenance are key to preventing leaks. Regularly clean and lubricate sealing components to prevent leakage caused by dirt or wear. Valves should be regularly inspected for wear on the sealing surface, wear on the trapezoidal threads of the valve stem and stem nut, accumulation of dirt between the valve body sealing surface and the gate sealing surface, and failure of the packing and gasket during use. After valve maintenance, a sealing test must be conducted.

here

for

price