- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Hastelloy G-35

Wire: 0.04-10mm

Strip: 0.05-15mm*3-600mm

Bar: 3mm~800mm;

Hastelloy G-35 Alloy Steel

Equivalent designations: UNS N06035, DIN W. Nr. 2.4643

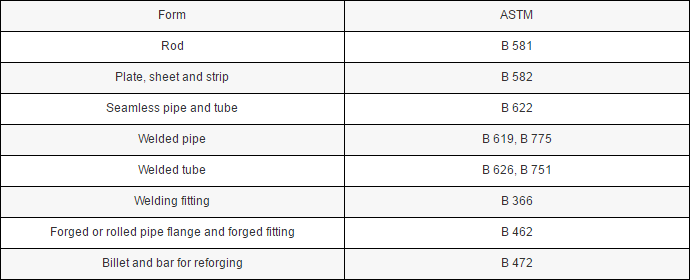

Chemical element for automotive fuse:

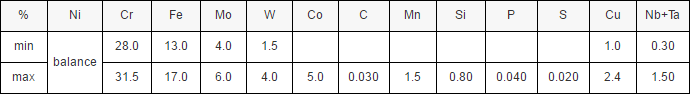

Physical properties:

Processing method:

Raw material→ Smelting→ Drawing→ Rolling→ Annealing→ Finished product→ Detection→ Packing→ Shipping

Packing:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

Advantages and Features:

Hastelloy G-30 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and sulfuric acids. It resists the formation of grain boundary precipitates in the heat-affected zone, making it suitable for use in most chemical process environments in the as-welded condition.

HASTELLOY G-35 alloy (UNS N06035) was designed to resist “wet process” phosphoric acid (P2O5), which is used in the production of fertilizers. Tests in real-world solutions indicate that G-35 alloy is far superior to other metallic materials in this acid. It was also designed to resist localized attack in the presence of chlorides, since this can be a problem beneath deposits in evaporators used to concentrate “wet process” phosphoric acid. Furthermore, G-35 alloy is much less susceptible to chloride-induced stress corrosion cracking than the stainless steels and nickel-chromium-iron alloys traditionally used in “wet process” phosphoric acid.

As a result of its very high chromium content, G-35 alloy is extremely resistant to other oxidizing acids, such as nitric, and mixtures containing nitric acid. It possesses moderate resistance to reducing acids, as a result of its appreciable molybdenum content, and, unlike other nickel-chromium-molybdenum alloys, it is very resistant to “caustic de-alloying” in hot sodium hydroxide.

here

for

price