- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

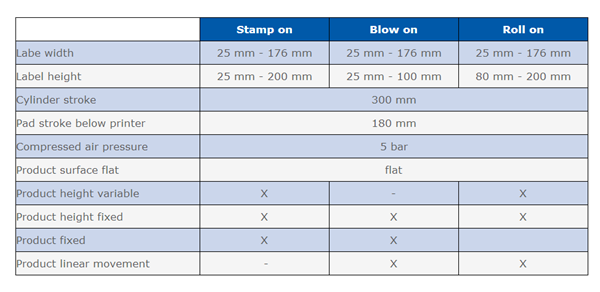

Label Printer& Applicator

Cylinder stroke: 300mm

Pad stroke below printer: 180mm

This applicator is an optional device to use with label printers of the Compa or Compa II series for automatically applying the printed label onto the product. The labels are transferred with a pad, which moves between the two positions, starting position and labeling position, by a compressed-air driven pneumatic cylinder. In the starting position, the label is picked up from the printer. A sensor at the cylinder signals when the pad is in the starting position. The label is removed from the carrier ribbon directly at the dispense edge of the printer. It is sucked on the pad by a vacuum via drillings at the bottom of the pad. For support, the label is also blown against the pad (supporting air) with an air current coming from a blow tube. The correct transfer of the label is controlled by a vacuum sensor.

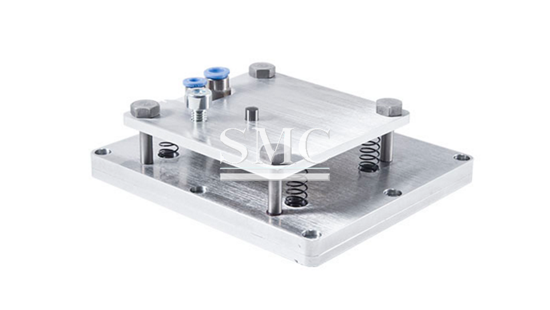

Tamp Pad

During the print and apply cycle the product remain fixed. The universal tamp is covered by a foil. According to the size of the label the holes can be pierced. The tamp pads are customized to the dimensions of the label sizes on request.

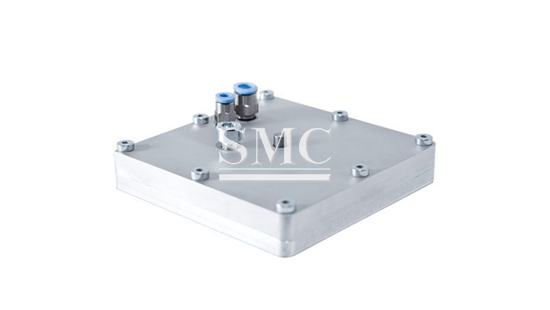

Blow Pad

For non-applying pressure to sensitive products the label can be blown onto the product with the supporting air jet stream. The print and apply cycle performs in a fixed position or in a linear movement of the product. The blow pad moves to a preadjusted position approx. 10mm away from the product.

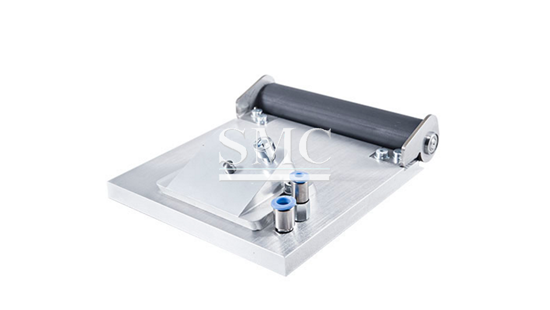

Roll-on Pad

In the starting position the label is forwarded until touching the roller of the roll on pad. At the labelling position the roller is pressed onto the product. Then the label is applied and rolled on by the movement of the product.

here

for

price