- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

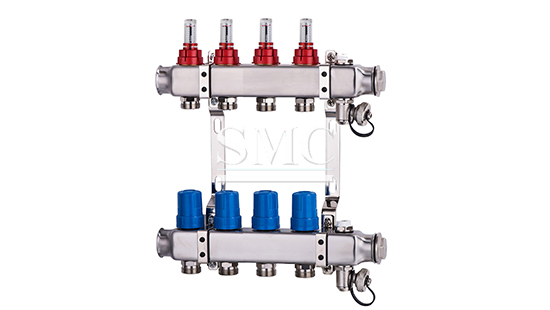

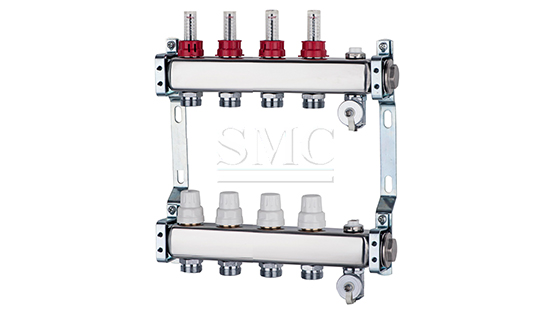

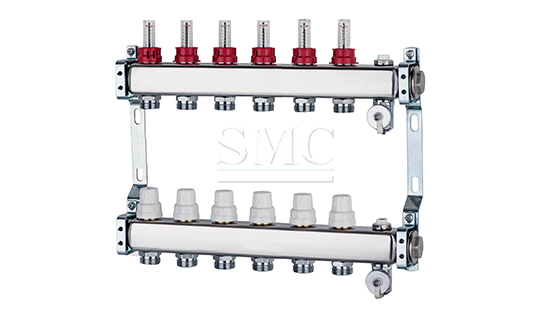

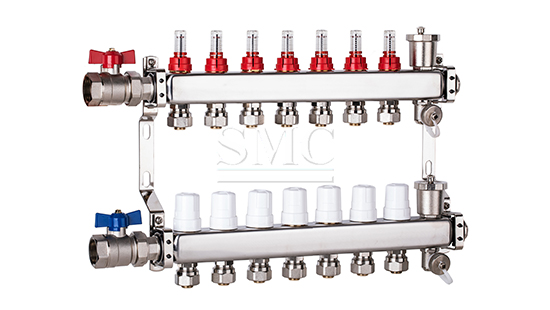

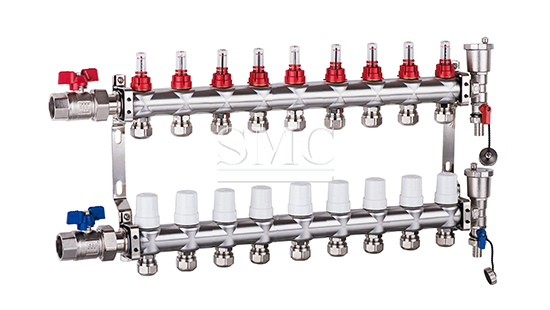

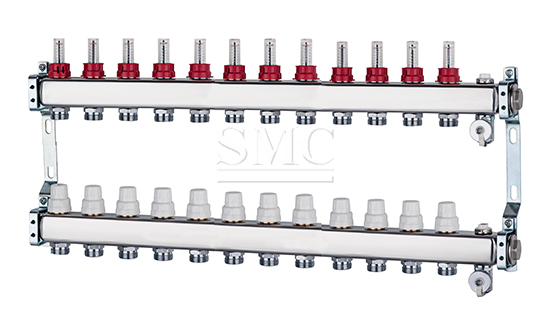

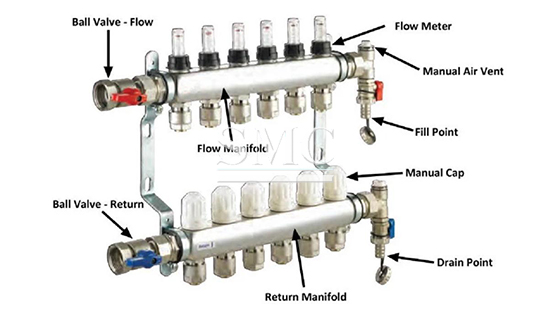

Manifold

Material: Stainless Steel, Brass, Nickel Plating

Function: Water distributor and control heating temperature in Floor Heating System

Port: 2-way, 3-way, 4-way, 5-way, 6way, 8way, 10way… etc.

Shanghai Metal Corporation is a leading Manifold manufacturer and supplier.

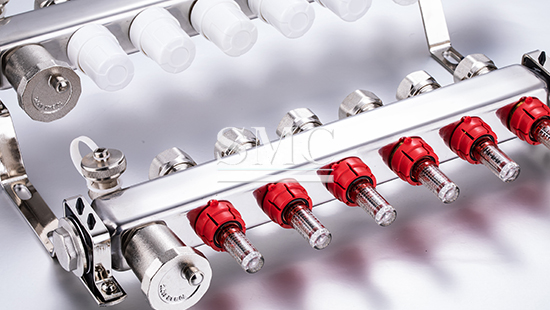

The Manifold is a device used to connect the main heating supply pipe and the return pipe in the floor heating system. It is divided into two parts: Flow Manifold and Return Manifold. The Flow Manifold is a water distribution device used to connect the water supply pipes of various heating pipes in the water system. The Return Manifold is a water collection device used to connect the return pipes of various heating pipes in the water system.

The main function of the Manifold is to distribute the hot water from the pipe network system through the floor heating pipes buried under the floor to the rooms that need floor heating. When the hot water flows in the floor heating pipe, it transfers heat to the floor, and then radiates heat through the floor to the room.

If you want to know more about our Floor Heating Piping System or Manifold price please feel free to contact us, we will reply you within 24 hours.

The following figure shows the basic composition structure of the Manifold:

SMC Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

The installation precautions of Manifold:

1. The manifold should not be installed in the bedroom, living room, nor in the storage room or cabinet.

Because the location of the manifold should be designed for proper control, maintenance, and drainage pipes. If installed in the bedroom, living room, storage room, etc., it will no longer be repaired, which will affect the efficiency and design of the room.

2. Different house structures should be analyzed in detail and treated differently. For semi-overfloor rooms, the manifold is suitable for installation at high or low places; for the type of duplex structure, the manifold is suitable for installation on the corresponding unified main pipes on the upper and lower floors;

3. The manifold should be installed before starting to install the floor heating pipe. The manifold is installed in the switch and special box, usually in the kitchen; the valve under the collector should be installed horizontally at a distance of 30cm or more from the floor; the water supply valve installation In front of the water trap, the return valve is installed under the water trap; the filter is installed in front of the water trap;

4. When installed horizontally, generally the water separator is more suitable for installation on the top, the water collector is installed below, the center distance of 200mm is the best, the center of the water collector should be no less than 300mm from the ground, if installed vertically, the lower end of the water collector is away from the ground It should not be less than 150mm.

5. When installing the water separator plug, wrap the threaded part of the plug with a certain amount of raw material tape, and then screw the plug into the right end of the water separator, because the plug thread of our company is a tapered sealing thread , The threaded joint does not need to be screwed into the main body completely, and the sealing effect can be achieved when the screw is not screwed. If excessive force is used, the main body tube will burst and crack.

6. There is a process of heating. Generally speaking, you cannot feel the temperature immediately after turning on the floor heating. Under normal circumstances, the temperature will be effective after two to three days. The water temperature of the floor heating should not exceed 65 degrees Celsius.

here

for

price