- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Pancake Copper Tube (Copper Tube Coil) for Transformer Components

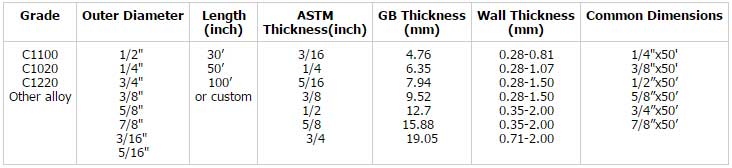

Grade: C11000, C10200, C12200, etc.

OD: 4mm - 22.23mm

Thickness: 0.03'' -0.44''

Length: 15m, 18m, 30m, 50m

Transformer copper content> 99.95%. Not allowed to contain scale, oil, coating, paint and other impurities. Do not contain wool,

car, debris and thickness <1mm copper. The advantages and disadvantages of the transformer can be divided into copper

transformer and half-copper transformer, the transformer coil to determine their own loss of size, the greater the loss of their own

output power less, so the use of copper is the best.

Specifications of Pancake Copper Tube/Copper Tube Coil for Transformer Components:

Features of Pancake Copper Tube/Copper Tube Coil:

1) Good electricity

2) Heat conduction

3) Good elongation

4) Being extruded and processed well

5) Good corrosion-resistance

6) Climate-hardiness

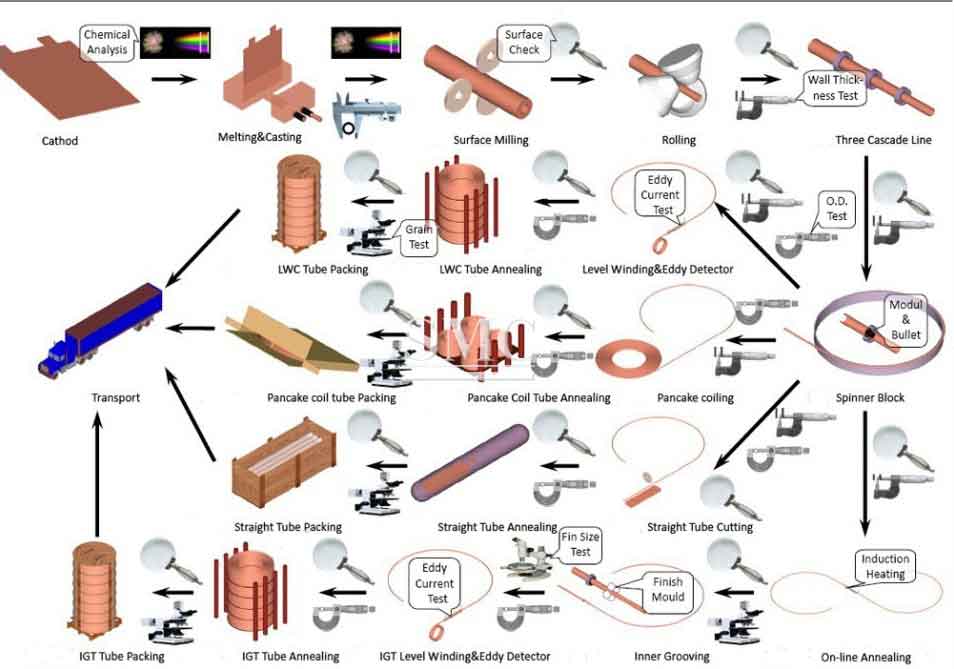

Manufacturing of Pancake Copper Tube/Copper Tube Coil

Packaging of Pancake Copper Tube/Copper Tube Coil

SMC Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) SMC Standard

2) Customization

Our Service

To meet the entirety of our customers business needs, SMC offers its services as a “One-Stop Shop” for business services including Purchasing, Value-Added Manufacturing, Packaging/Labeling, and Delivery. SMC prides itself on achieving superior results and satisfying customer needs. In this, we earnestly strive to fulfill our role as trustworthy and reliable supplier of business services throughout the entire world.

Our Value-Added Manufacturing Services not only save our customer time from having to out-source, but also spare them the cost of dealing with several disparate shops and deadlines.

Applications of Pancake Copper Tube/Copper Tube Coil:

1) Air conditioning/refrigeration

2) Heat exchange use

3) Connecting tube

4) Distribution

5) Fire protection, solar, fuel/fuel Oil

6) Natural gas, liquefied petroleum (LP) gas

7) HVAC, snow melting, drain, waste, vent piping

here

for

price

.jpg)