- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

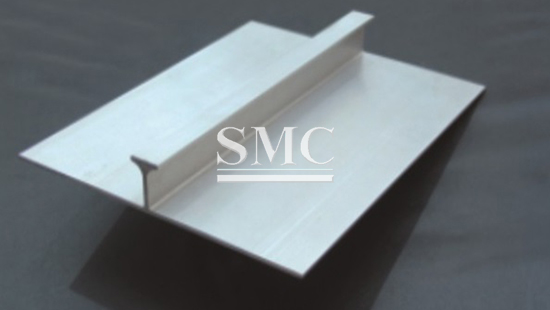

Ultra Wide Extruded Reinforced Sheet

Welding method: Friction stir welding

Material: Aluminum alloy LF6

Normal width: 250mm, 380mm, Up to 600mm

Shanghai Metal Corporation is one of the leading and reliable manufacturers and exporters of Ultra-wide Extruded Reinforced Sheet in China. We provide the high quality matched products and excellent services for various industries.

Shanghai Metal Corporation is one of the leading and reliable manufacturers and exporters of Ultra-wide Extruded Reinforced Sheet in China. We provide the high quality matched products and excellent services for various industries.

If you want to know more about our Ultra-wide Extruded Reinforced Sheet, please feel free to contact us, we will reply you within 24 hours.

1, LF6 aluminum alloy ingot is pretreated, and the pretreated ingot is homogenized and annealed at 450-480°C for 12h, and then placed in the extrusion barrel of the extruder.

2. Heat the product mold in the extrusion cylinder to 450-500°C, control the temperature of LF6 aluminum alloy ingot to 380-410°C, control the temperature of extruder outlet to 300-340°C, and clamp the working table with the product mold and the extrusion cylinder.

3, The extrusion barrel in the extruder runs toward the product mold at an extrusion speed of 2.5-3.5m/min, extrudes the LF6 aluminum alloy ingot, and the LF6 aluminum alloy ingot is extruded out of the die hole of the product mold to obtain the LF6 aluminum alloy reinforced plate slat, in which the LF6 aluminum alloy ingot is heated by a segmented gradient heating method, and the head of the extruding barrel is heated at a temperature of 440-460°C, and the middle of the heating The head of the extrusion cylinder is heated at a temperature of 440-460°C, the middle is heated at a temperature of 440-460°C, and the tail is heated at a temperature of 370-390°C.

4, The LF6 aluminum alloy with ribbed plate slat made in step C is quenched, and the quenching method is the synchronous method of air cooling and atomized cooling, and the temperature of the quenched LF6 aluminum alloy with ribbed plate slat is 120-130°C.

5, The quenched LF6 aluminum alloy reinforced plate slat is subjected to aging heat treatment, the aging temperature is 180-220°C, and the aging time is 3-8h.

6, Welding for large width LF6 aluminum alloy strip plate.

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price