- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

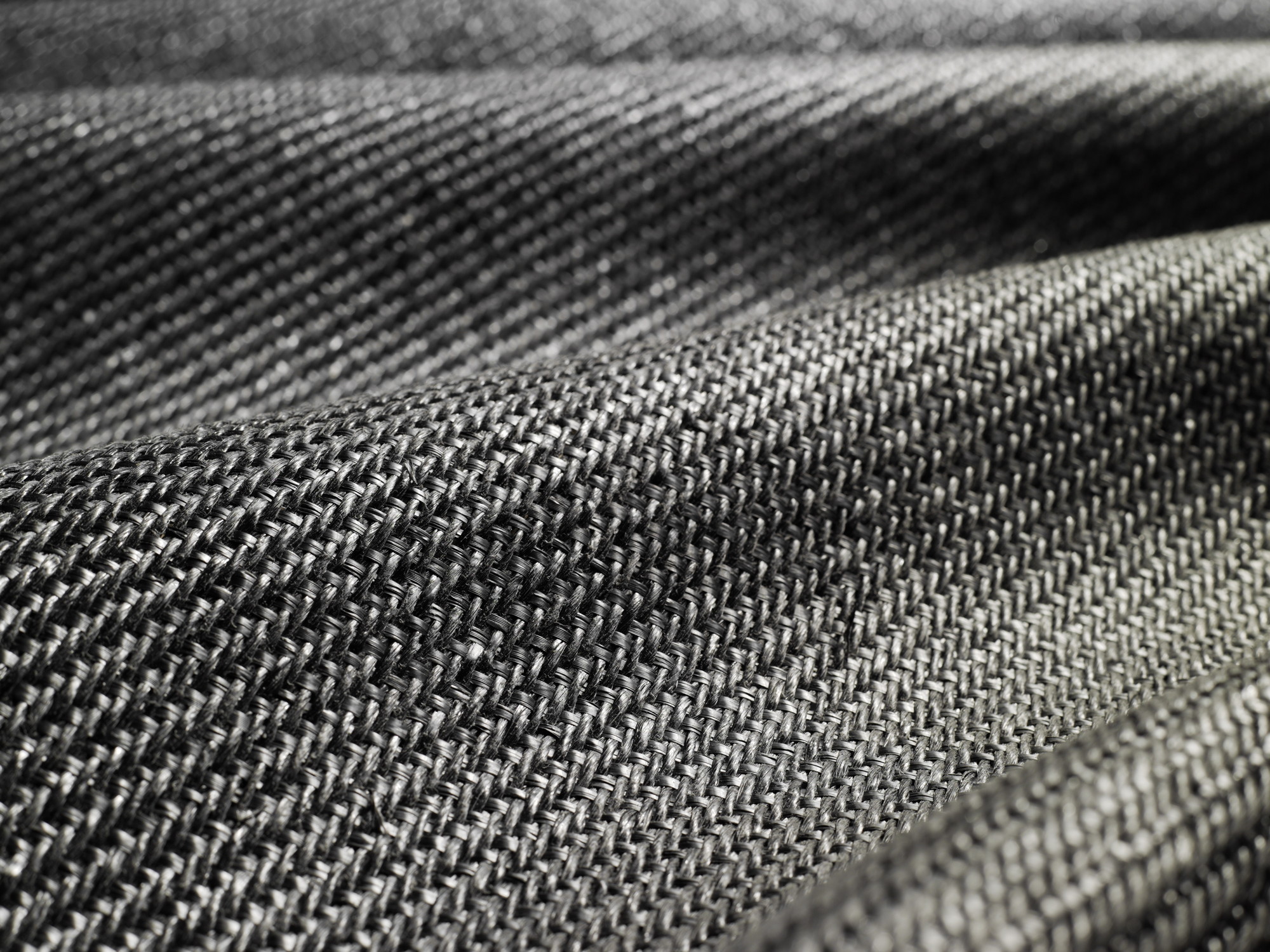

What permeable geosynthetic comprised solely of textiles means and what are the types of it?

History

According to the historical record, it is believed that the first applications of geotextiles were woven industrial fabrics used in 1950’s. One of the earliest documented cases was a waterfront structure built in Florida in 1958. Then, the first nonwoven geotextile was developed in 1968 by the Rhone Poulence company in France. It was comparatively thick needle-punched polyester, which was used in dam construction in France during 1970.

In fact, the geotextile is one of the members of the geosynthetic family.

What is geotextile?

As we know, the prefix of geotextile, geo, means earth and the ‘textile’ means fabric. Therefore, according to the definition of ASTM 4439, the geotextile is defined as follows:

"A permeable geosynthetic comprised solely of textiles. Geotextiles are used with foundation, soil, rock, earth, or any other geotechnical engineering-related material as an integral part of human-made project, structure, or system."

According to The ASAE (Society for Engineering in Agricultural, Food, and Biological Systems) , geotextile as a "fabric or synthetic material placed between the soil and a pipe, gabion, or retaining wall: to enhance water movement and retard soil movement, and as a blanket to add reinforcement and separation."

A geotextile should consist of a stable network that retains its relative structure during handling, placement, and long-term service. Other terms that are used by the industry for similar materials and applications are geotextile cloth, agricultural fabric, and geosynthetic.

The types of geotextile

In general, the vast majority of geotextiles are made from polypropylene or polyester formed into fabrics as follows woven monofilament, woven multifilament, woven slit-film monofilament, woven slit-film multifilament, nonwoven continuous filament heat bonded, nonwoven continuous filament needle-punched, nonwoven staple needle-punched, nonwoven resin bonded, other woven and nonwoven combinations, knitted.

Raw material of geotextile

The four main polymer families most widely used as the raw material for geotextiles arepolyester, polyamide, polypropylene, polyethylene.

The oldest of these is polyethylene, which was discovered in 1931 in the research laboratories of the ICI. Another group of polymers with a long production history is the polyamide family, the first of which was discovered in 1935.The next oldest of the four main polymer families relevant to geotextile manufacture is polyester which was first announced in 1941.The most recent polymer family relevant to geotextiles to be developed was polypropylene, which was discovered in 1954.

The basic properties of geotextile

The properties of polymer material are affected by its average molecular weight (MW ) and its statistical distribution. Increasing the average MW results in increasing tensile strength,elongation,impact strength, stress crack resistance, heat resistance,

Narrowing the molecular weight distribution results in increased impact strength, decreased stress crack resistance, decreased process ability,

Increasing crystalline results in increasing stiffness or hardness, increasing heat resistance, increasing tensile strength, increasing modulus, increasing chemical resistance, decreasing diffusive permeability, decreasing elongation or strain at failure, decreasing flexibility, decreasing impact strength, decreasing stress crack resistance.

Functions

There are at least 80 specific applications areas for geotextiles that have been developed; however, the fabric always performs at least one of five discrete functions:

Separation

Geotextiles function to prevent mutual mixing between 2 layers of soil having different particle sizes or different properties.

Drainage

The function of drainage is to gather water, which is not required functionally by the structure, such as rainwater or surplus water in the soil, and discharge it.

Filtration

Filtration involves the establishment of a stable interface between the drain and the surrounding soil. In all soils water flow will induce the movement of fine particles. Initially a portion of this fraction will be halted at the filter interface; some will be halted within the filter itself while the rest will pass into the drain. The geotextile provides an ideal interface for the creation of a reverse filter in the soil adjacent to the geotextile. The complex needle-punched structure of the geotextile provides for the retention of fine particles without reducing the permeability requirement of the drain.

Reinforcement

Due to their high soil fabric friction coefficient and high tensile strength, heavy grades of geotextiles are used to reinforce earth structures allowing the use of local fill material.

Protection

Erosion of earth embankments by wave action, currents and repeated drawdown is a constant problem requiring the use of non-erodible protection in the form of rock beaching or mattress structures. Beneath these is placed a layer of geotextile to prevent leaching of fine material. The geotextile is easily placed, even under water.