- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

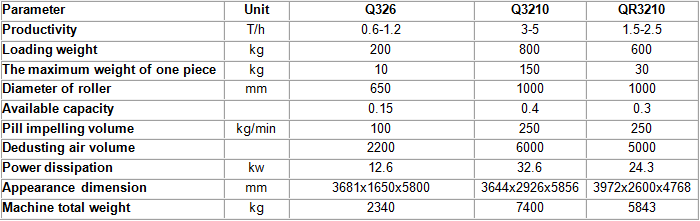

Shot Blasting Machine

Parameter: 0.6-1.2/3-5/1.5-2.5 T/h

This series is used for surface cleaning, rust removing, and surface intensification of each kind of middle and small scale casting, forging and so on. It is suitable for different production scale, can be stand-alone use and many units can also be used in conjunction with the continuous conveyor components, composing the production of clean-up lines.

Q32 series abrade cleaning up machine has the advantages of advanced design, reasonable structure small energy consumption and high efficiency.

This machine normally used for blasting of casting, forging, spare parts. After the power supply is opened, start the dust collector and elevator ect, the preparation work completed. The workpieces put into the cleaning chamber and landed on the rubber crawler. Then, close the door of cheaning chamber, start the blasting wheel and shot gate, begin to shot blasting. At the same time, the crawler rolls around, causing the workpiece to roll continuously to ensure that it is cleaned evenly. Splashed steel shot will into screw conveyor through the holes of rubber crawler, and into the bottom of elevator, then lift it vertically to the top separator. Finally, the steel shot that has been separated and purified will into the shot blasting wheel through shot gate. Blasting time (according to the workpiece situation setting) controlled by time relay. After finished, the shot gate and blasting wheel will stop running. Then, open the cleaning chamber door, let the track rotated backward, so that the workpieces have been cleaned will be discharge.

here

for

price