- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

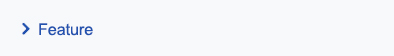

API Oil Drilling Pipe/ Oil Well Drilling Pipe

Diameter of Casing pipe: 4 1/2 "-20", tube:2 3/8 "-5"

Strength grade: API E75-S135 and other materials.

Length range:R1:18-22ft,R II : (27-30ft); R III: (38-45ft)

Shanghai Metal Corporation is a leading API Oil Drilling Pipe manufacturer and supplier.

The API Oil Digging Pipe is mainly used in oil, all-natural gas, coal bed methane, water digging up design, and various other markets. Drill pipes are divided into three categories: square drill pipes, drill pipes and weighted drill pipes. The order of connection is square drill pipe (1 piece) + drill pipe (n pieces, determined by the depth of the well) + weighted drill pipe (n pieces, determined by the design of the combination of drilling tools). Drill pipe is the basic component of the drilling column. Its main role is to transmit torque and transport drilling fluid, and rely on the gradual lengthening of the drill pipe to make the borehole deeper and deeper. Therefore, drill pipe occupies a very important position in oil drilling.

In the corrosive environment, the casing itself is also required to have corrosion resistance. Drill pipe is a steel tube with threads on the end that is used to connect the surface equipment of a drilling rig to the drill milling equipment or bottom hole device located at the bottom end of the drilled well. The purpose of drill pipe is to transport drilling mud to the drill bit and to raise, lower or rotate the bottom hole device with the drill bit. Drill pipe must be able to withstand great internal and external pressure, twisting, bending and vibration. Drill pipe can be used multiple times during the extraction and refining of oil and gas.

If you want to know more about our steel pipe products or API Oil Drilling Pipe price please feel free to contact us, we will reply you within 24 hours.

Specification:

|

Size(inch) |

Weight Designation |

Calculated Plain-End weight |

Outside Diameter |

Wall Thickness |

|||

|

Lb/ft |

Kg/m |

inch |

mm |

inch |

mm |

||

|

2‐3/8 |

6.65 |

6.26 |

9.32 |

2.375 |

60.3 mm |

0.28 |

7.11 mm |

|

2‐7/8 |

10.4 |

9.72 |

14.48 |

2.875 |

73.0 mm |

0.362 |

9.19 mm |

|

3‐1/2 |

9.5 |

8.81 |

13.12 |

3.5 |

88.9 mm |

0.254 |

6.45 mm |

|

3‐1/2 |

13.3 |

12.31 |

18.34 |

3.5 |

88.9 mm |

0.368 |

9.35 mm |

|

3‐1/2 |

15.5 |

14.63 |

21.79 |

3.5 |

88.9 mm |

0.449 |

11.40 mm |

|

4 |

14 |

12.93 |

19.26 |

4 |

101.6 mm |

0.33 |

8.38 mm |

|

4‐1/2 |

13.75 |

12.24 |

18.23 |

4.5 |

114.3 mm |

0.271 |

6.88 mm |

|

4‐1/2 |

16.6 |

14.98 |

22.31 |

4.5 |

114.3 mm |

0.337 |

8.56 mm |

|

4‐1/2 |

20 |

18.69 |

27.84 |

4.5 |

114.3 mm |

0.43 |

10.92 mm |

|

5 |

16.25 |

14.87 |

22.15 |

5 |

127.0 mm |

0.296 |

7.52 mm |

|

5 |

19.5 |

17.93 |

26.71 |

5 |

127.0 mm |

0.362 |

9.19 mm |

|

5 |

25.6 |

24.03 |

35.79 |

5 |

127.0 mm |

0.5 |

12.70 mm |

Strength:

|

Group |

Grade |

Yield Strength |

Tensile Strength |

||||

|

Minimum |

Maximum |

Minimum |

|||||

|

Psi |

Mpa |

Psi |

Mpa |

Psi |

Mpa |

||

|

1 |

E-75 |

75000 |

517 |

105000 |

724 |

100000 |

689 |

|

2 |

X-95 |

95000 |

655 |

125000 |

862 |

105000 |

724 |

|

G-105 |

105000 |

724 |

135000 |

931 |

115000 |

793 |

|

|

S-135 |

135000 |

931 |

165000 |

1138 |

145000 |

1000 |

|

here

for

price