- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Chromium Zirconium Copper Bar

Shanghai Metal Corporation is a leading Chromium zirconium copper bar manufacturer and supplier.

The chromium-zirconium copper rod (CuCrZr) is composed of three kinds of metals, which has high hardness, good wear resistance and explosion resistance, and high softening temperature (hardness >75HRB; after 2 hours at 550 °C, the quenching cooling is not lower than the original hardness. More than 15%; the average value of three-point conductivity is ≥44MS/M measured by eddy current conductivity meter.) It is a good welding material with good crack resistance. Common grades are QCr1-0.15 and QCr0.6-0.4. , QCr0.5, C18150, C18200 and so on. We also can provide Chromium Zirconium Copper Electrode Cap.

If you want to know more about our copper bar products or Chromium zirconium copper bar price please feel free to contact us, we will reply you within 24 hours.

-

1) Grade: C18150,C18200,C1500;C18000

2) Length:2~3.6 meter

3) Diameter: 2~100mm

4) High strength(Rm:≥450Mpa,HRB:70-86)

5) High conductivity(conductivity IACS%:75-83

-

-

-

1) High strength: tensile strength> 450Mpa

2) High hardness:HRB70-86 HB120-165

3) High conductivity: conductivity> 75%

4) High softening point:475-600°C

5) High wear resistant high heat-resisting

6) High anti-deformation ability

-

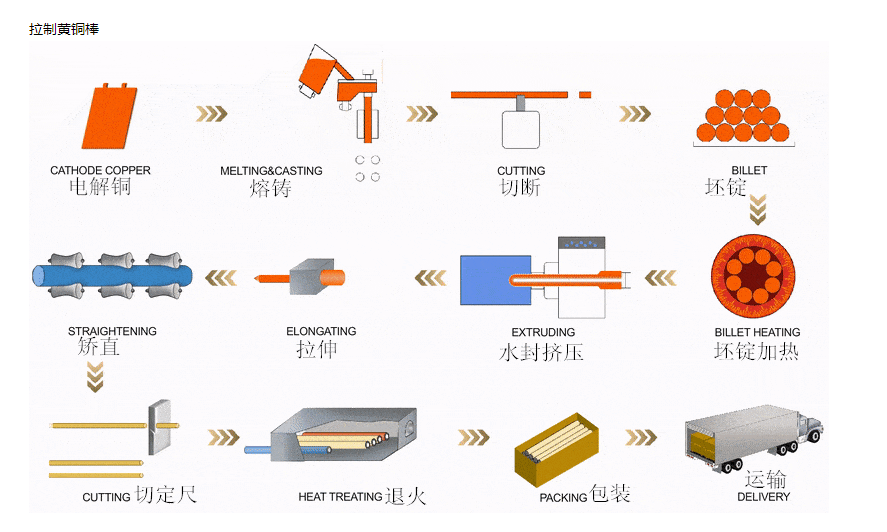

1) Material Melting

2) Casting

3) Extruding

4) Drawing

5) Straightening

6) Annealing

-

-

-

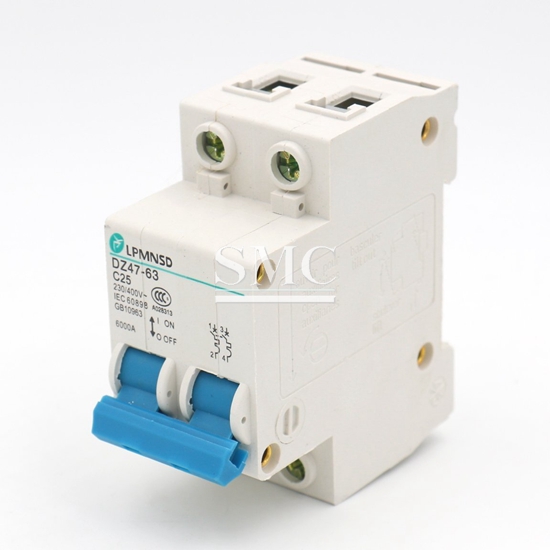

1Widely used for automobile and spaceship stencil plate and contact welding stainless steel. Ideal electrode material for seal welder, high-voltage switch welding material and circuit breaker material, best high-strength, high conductivity and high melting-point material used for continuous crystallization device in metallurgical trade, and widely used for lead frame.

-

1) Hardness

2) Tensile Strength

3) Elongation

4) Metal-Detector

5) Conductivity

6) Chemical Content

-

Chemical Composition of Chromium zirconium copper bar:

1. C18150/CuCr1Zr/CW106C

Cr:0.50-1.50%; Zr:0.05-0.25% ;Cu:balance

Cu+Cr+Zr:99.5%min

2.C18200/CuCr/CW105C

Cr:0.60-1.20%;Cu:balance

Cu+Cr:99.5%min

3.C18000/CuNi2CrSi/CW111C

Cr:0.10-0.80%;Ni:1.80-3.0%;Si:0.40-0.8%;Cu:balance

Cu+Cr+Ni+Si:99.5%min

4.C15000/CuZr/CW120C

Zr:0.15-0.20%

Cu:balance

Cu+Zr:99.5%min

Characteristics of Chromium zirconium copper bar:

High strength(Rm:≥450Mpa,HRB:70-86),high conductivity(conductivity IACS%:75-83),heat wear resisting, distortion prevention

Features of Chromium zirconium copper bar:

1.high strength: tensile strength> 450Mpa

2.high hardness:HRB70-86 HB120-165

3.high conductivity: conductivity> 75%

4.high softening point:475-600°C

5.high wear resistant high heat-resisting

6.High anti-deformation ability

7.long serving life

Packaging of Chromium Zirconium Copper Bar :

Application of Chromium zirconium copper bar:

Widely used for automobile and spaceship stencil plate and contact welding stainless steel. Ideal electrode material for seal welder, high-voltage switch welding material and circuit breaker material, best high-strength, high conductivity and high melting-point material used for continuous crystallization device in metallurgical trade, and widely used for lead frame.

Advantages of Chromium zirconium copper bar:

1.We can provide specific forms according to customers' requests

2.We are also a manufacturer,so we can provide the products in conformity with your requirements

3.Our company has rich technical force and advanced production equipment and coordinated advanced test equipment and method

here

for

price