- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Cold Heading Quality Steel Wire Rod for Automobile (CHQ Wire Rod)

Cold Heading Quality Steel Wire Rod (CHQ Wire Rod) involves particular raw materials

and chemistry to withstand swedging and heading and forming with great quality.

It is suitable for fastener and cold heading applications such as bolts, nuts, screws, rivets, nails, etc.

Specifications of Cold Heading Quality Steel Wire Rod (CHQ Wire Rod):

1) Brand: SMC

2) Wire diameter: 5.5mm - 30mm

3) Coil weight: 2,000kg

4) Grade: SUJ2, SWCH6A-10A, SWCH12A-45K, SCM415-420, SCM435-440,

SCr415-440, SWCH6A-22A, SWCH6A, SNCM240, SCr415-420, SCr435-440,

SCM415-420, SCM435-440, SCr415-420, SCM415-420, etc.

5) Technic Process: Pickling & coating, Intermediate drawing, Spheroidized annealing, Skin pass

6) Diameter tolerance: +/-0.04mm for below 10mm, and above 10mm +/-0.55mm

Process of Cold Heading Quality Steel Wire Rod:

Pickling & coating

The hot-rolled coil or wire rod passes through the pickling line,

where hydrochloric acid solution is used to remove surface scale for

clean surface finish before further processing and to form a lubrication film

on the surface to reduce the coefficient of friction in the drawing and

cold working process. The Gantry Crane moves between the tank during the process.

Intermediate drawing

This process which produces half-finished products for the following stage

improves the spherodized ratio during spheroidized annealing. The wire

drawing machine composed of Supply Stand ,Drawing Drum, Take up

stages produces half-finished coil products.

Spheroidized annealing

This annealing process with the purpose of obtaining spheroidized

carbides facilitates the cold works. Once inserted in the heat treatment

furnace, the process takes place in the order of controlled heating up to

a given time, temperature and furnace atmosphere, along with maintenance

at such temperature during a certain period and cooling controlled in accordance

with the purpose intended. This process is controlled by automatic heat cycle.

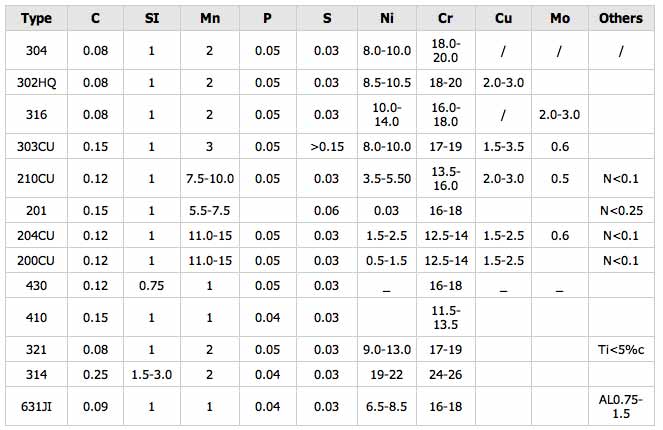

Chemical composition of Cold Heading Quality Steel Wire Rod:

Packaging of Cold Heading Quality Steel Wire Rod

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Features of Cold Heading Quality Steel Wire Rod:

1) High strength and hardness

2) High production efficiency

3) Low cost and strong fatigue resistance

4) Grain flow which improves the finished part grain structure

Applications of Cold Heading Quality Steel Wire Rod:

1) Automative:

a) Engine: spark plug shell, cylinder head bolt, piston rod, etc.

b) Steering system (ball joint stud, tie rod pin, pinion, etc.)

c) Wheel: hub bolt, nut, etc.

2) Airplanes: High-tension bolts for wings

3) Bearing : roller bearing, ball bearing, etc.

4) Construction: fastener bolt, etc.

5) Electronic parts: Material for Switch Relay

6) Industrial machines & Electronic parts : fastener bolt, nut, screw, etc.

here

for

price