- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

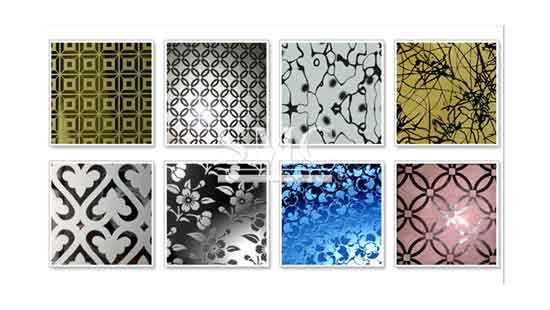

Etched Stainless Steel Sheet for Elevator Hall Door

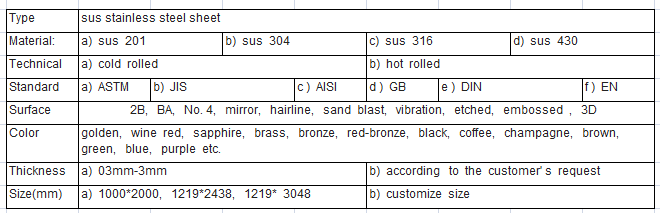

Grade: SUS304, SUS316, etc.

Sizes: 1000mm*2000mm, etc.

Specifications of Etched Stainless Steel Sheet for Elevator Hall Door:

Manufacturing of Stainless Steel Sheet for Elevator Hall Door

1) Raw materials are sending to hot rolling units for rolling into different sizes

2) Hot rolled material is annealing in cold rolled annealing furnace and pickling in acid

3) All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation

4) All sheets are pickled in different tanks and dried on brush roll machine before dispatched

5) These sheets are again annealing and are sent to straighten machine for straightening

6) Inspections are done at various stages. Keep proper control overall internal process via rolling, annealing and pickling by our experienced staff

Packaging of Stainless Steel Sheet for Elevator Hall Door

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Etched Stainless Sheet for Elevator Hall Door:

1) Building applications

a) Column covers

b) Elevator doors

c) Escalators and moving walk cladding

d) Ornamental and decorative cladding

e) Hotel entrances

f) Architectural trims and accents

g) Telephone booth, etc.

2) Home fixture applications:

a) Kitchen appliances

b) Cabinets

c) Doors

d) Mail boxes, etc.

3) Industrial fixtures applications:

a) Medical instruments

b) Electrical products

c) Refrigerator

d) Hardware, etc.

here

for

price