- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Heavy Duty Steel Grating For Ceiling

Bearing bar pitch (mm): 30, 34.3, 40 & 60

Cross bar pitch: 100, 76, 50

Standards: YB/T4001.1-2007, BS4592, AS1657

Specifications of Heavy Duty Steel Grating:

1) The shape of bearing bar: Plain type (may be omitted in the

symbol of steel grating), Serrated type and I-Shape type

2) Bearing bar pitches can be 12.5, 15, 20, 30, 30.16, 32.5,

34.3, 40, 60, 80mm, of which 30mm & 40mmare recommended

3) Cross bar pitches can be 40, 50, 60, 65, 76, 100, 101.6,

120mm are recommended

4) Surface treatment: Hot-dip galvanizing, paint or other

anti-corrosive coatings are available, of which hot-dip galvanizing

is generally recommended

5) Material: Carbon steel/ stainless steel

6) Tolerance

The allowed deviation of length is +0/-5mm, while the allowed deviation of width is +/-5 mm.

The non-perpendicularity of bearing bar is allowed no more than 10% of width of bearing bar.

Cross bar surface should not surpass bearing bar surface 1mm, beginning & end of cross bar

should not surpass the end surfaces of two sides of grating 2mm.

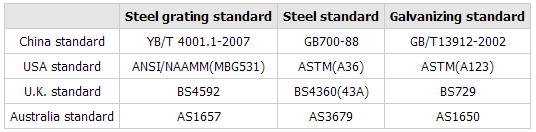

7) Standard:

Popular Types of Heavy Duty Steel Grating:

1) Steel grating with 30mmx50mm bearing bar pitch is the most widely used in industrial area.

Among the general series, it maintains the strongest resistance to impulsive force.

2) Steel grating with 40mmx50mm bearing bar pitch is one of the most economical & lightest

types. It should be the best choice to customer on the occasion when the clear span is small.

3) Steel grating with 60mmx50mm bearing bar pitch & 50mm cross bar pitch is developed

specially for mining industry. As it can avoid the mineral splashing down on board, it’s

appointed to use in fabrication plant, transfer terminal & other areas of mining.

Manufacturing of Heavy Duty Steel Grating

Material → Welding → Cutting → End plate welding → Surface treatment → Final shipment

Saddle Clip Heavy Duty Steel Grating:

Type A saddle clip- composed of a top board with double hooks, a holding down plate with

teeth and M8 inner-hexagon-bolt.

Type B saddle clip- composed of a top board with double hooks (one of hooks can draw

together the two neighboring steel gratings),

and a holding down plate with teeth and a M8 inner-hexagon-bolt.

Type C saddle clip-composed of a top board with double hooks and a M8 hexagon-bolt

can be welded in supporting structure

Packaging of Heavy Duty Steel Grating

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Heavy Duty Steel Grating:

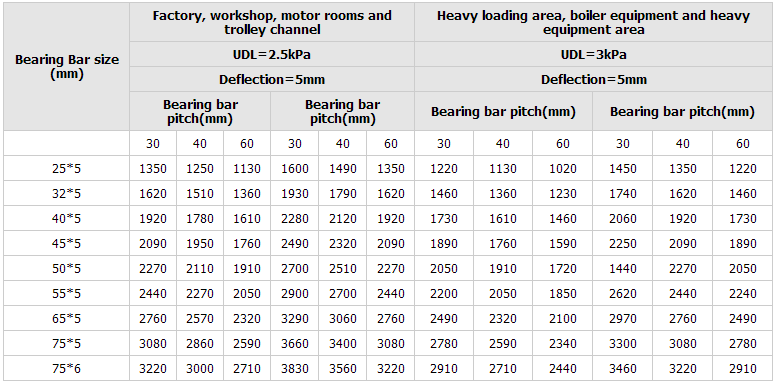

Heavy Duty Steel grating can be used in the fields of heavy loaflooring, catwalk, mezzanines/decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, pedestrian/crowded pedestrian, factory, workshop, motor rooms, trolley channel, heavy loading area, boiler equipment and heavy equipment area, etc.

1) Plain: one of the most widely used gratings, available for flooring, sidewalk, drainage pit cover, stair tread, etc.

2) Serrated: better non-skid property & safety compared with plain grating

3) I-shape: lighter, more economical and practical comparing with plain grating

Instruction of Selecting Heavy Duty Steel Grating:

here

for

price