- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

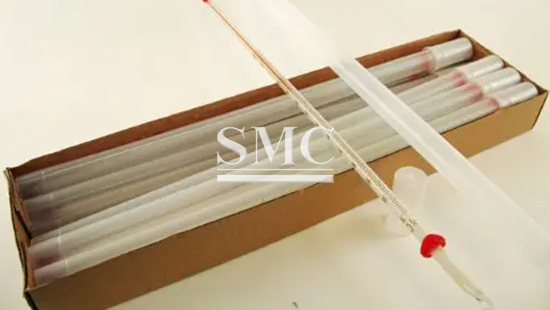

Industrial Glass Thermometer

Cross Section: Round, Triangle

Immersion: Total Immersion, Partial Immersion

MOQ: 1000PCS

Shanghai Metal Corporation is a professional manufacturer and supplier of Industrial Glass Thermometer with high quality and reasonable price.

Glass thermometer is a traditional temperature measurement product that is made through more than ten processes such as manual firing and liquid filling, with low cost, accurate measurement, convenient use, and no need for power supply. Widely used in production and daily life. Using round or triangular glass rods as raw materials and mercury or organic solutions (kerosene, alcohol, etc.) as temperature sensing liquids, various products suitable for different needs are produced.

From the perspective of usage, it can be divided into two types: full immersion thermometers and partial immersion thermometers. Full immersion thermometers require placing all glass thermometers into the object being measured when measuring liquids, while partial immersion thermometers only need to be immersed in the designated position indicated on the thermometer; From the form of the scale surface, it can be divided into acid etched scale and silk screen scale. Acid etched scale is a corrosion carving technique that writes the scale value on a glass rod. Silk screen scale uses silk screen printing technology to print digital line graphics on glass, and then undergoes heat treatment to form a glazed effect in colors such as reddish brown and black. It is resistant to acid, alkali, and oil corrosion. It does not fade, and never wears out.

If you want to know more about Industrial Glass Thermometer price please feel free to contact us, we will reply you within 24 hours

Technical Information of Industrial Glass Thermometer:

|

Technical Information |

||||||

|

Model |

Measuring Range(℃) |

Accuracy(℃) |

Shape |

Total Length(mm) |

Outer Diameter(mm) |

Immersion Depth(mm) |

|

ASTM 1C |

-20~150 |

1 |

Rod |

322±5 |

6~7 |

76 |

|

ASTM 2C |

-5~300 |

1 |

Rod |

390±5 |

6~7 |

76 |

|

ASTM 3C |

-5~400 |

1 |

Rod |

415±5 |

6~7.5 |

76 |

|

ASTM 5C |

-38~50 |

1 |

Rod |

230±5 |

6~8 |

108 |

|

ASTM 6C |

-80~20 |

1 |

Rod |

230±5 |

6~8 |

76 |

|

ASTM 7C |

-2~300 |

1 |

Rod |

385±5 |

6~8 |

Total Immersion |

|

ASTM 8C |

-2~400 |

1 |

Rod |

385±5 |

6~8 |

Total Immersion |

|

ASTM 9C |

-5~110 |

0.5 |

Rod |

290±5 |

6~7 |

57 |

|

ASTM 10C |

90~370 |

2 |

Rod |

290±5 |

6~7 |

57 |

|

ASTM 11C |

-6~400 |

2 |

Rod |

310±5 |

6~8 |

25 |

|

ASTM 12C |

-20~102 |

0.2 |

Rod |

420±5 |

6~8 |

Total Immersion |

|

ASTM 13C |

155~170 |

0.5 |

Rod |

155±5 |

5.5~7 |

Total Immersion |

|

ASTM 14C |

38~82 |

0.1 |

Rod |

375±5 |

6~8 |

79 |

|

ASTM 15C |

-2~80 |

0.2 |

Rod |

395±5 |

6~8 |

Total Immersion |

|

ASTM 16C |

30~200 |

0.5 |

Rod |

395±5 |

6~8 |

Total Immersion |

|

ASTM 17C |

19~27 |

0.1 |

Rod |

375±5 |

6~7 |

Total Immersion |

|

ASTM 18C |

34~42 |

0.1 |

Rod |

275±5 |

6~7 |

Total Immersion |

|

ASTM 19C |

49~57 |

0.1 |

Rod |

275±5 |

6~7 |

Total Immersion |

|

ASTM 20C |

57~65 |

0.1 |

Rod |

275±5 |

6~7 |

Total Immersion |

|

ASTM 21C |

79~87 |

0.1 |

Rod |

275±5 |

6~7 |

Total Immersion |

|

ASTM 22C |

95~103 |

0.1 |

Rod |

275±5 |

6~7 |

Total Immersion |

|

ASTM 23C |

18~28 |

0.2 |

Rod |

212±5 |

5.5~6.5 |

90 |

|

ASTM 24C |

39~54 |

0.2 |

Rod |

237±5 |

5.5~6.5 |

90 |

|

ASTM 25C |

95~105 |

0.2 |

Rod |

212±5 |

5.5~6.5 |

90 |

|

ASTM 26C |

130~140 |

0.1 |

Rod |

463±5 |

6.5~8 |

Total Immersion |

|

ASTM 27C |

147~182 |

0.5 |

Rod |

301±5 |

6.5~7 |

76 |

|

ASTM 28C |

36.6~39.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 29C |

52.6~55.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 33C |

-38~42 |

0.2 |

Rod |

420±5 |

6~7.5 |

50 |

|

ASTM 34C |

25~105 |

0.2 |

Rod |

420±5 |

6~7.5 |

50 |

|

ASTM 35C |

90~170 |

0.2 |

Rod |

420±5 |

6~7 |

51 |

|

ASTM 36C |

-2~68 |

0.2 |

Rod |

395±5 |

6~7 |

45 |

|

ASTM 37C |

-2~52 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 38C |

24~78 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 39C |

48~102 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 40C |

72~126 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 41C |

98~152 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 42C |

95~255 |

0.5 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 43C |

-51.6~-34 |

0.1 |

Rod |

417.5±7.5 |

7~8 |

Total Immersion |

|

ASTM 44C |

18.6~21.4 |

0.05 |

Rod |

305±5 |

6.5~8 |

Total Immersion |

|

ASTM 45C |

23.6~26.4 |

0.05 |

Rod |

305±5 |

6.5~8 |

Total Immersion |

|

ASTM 46C |

48.6~51.4 |

0.05 |

Rod |

305±5 |

6.5~8 |

Total Immersion |

|

ASTM 47C |

58.6~61.4 |

0.05 |

Rod |

305±5 |

6.5~8 |

Total Immersion |

|

ASTM 48C |

80.6~83.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 49C |

20~70 |

0.2 |

Rod |

305±5 |

5.5~6 |

65 |

|

ASTM 52C |

-10~5 |

0.1 |

Rod |

162±5 |

6~6.5 |

Total Immersion |

|

ASTM 54C |

20~100.6 |

0.2 |

Rod |

310±5 |

6~8 |

Total Immersion |

|

ASTM 56C |

19~35 |

0.02 |

Rod |

585±15 |

7~8 |

Total Immersion |

|

ASTM 57C |

-20~50 |

0.5 |

Rod |

287±5 |

6~7 |

57 |

|

ASTM 58C |

-34~49 |

0.5 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 59C |

-18~82 |

0.5 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 60C |

77~260 |

1 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 61C |

32~127 |

0.2 |

Rod |

380±5 |

6~8 |

79 |

|

ASTM 62C |

-37~2 |

0.1 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 63C |

-8~32 |

0.1 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 64C |

25~55 |

0.1 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 65C |

50~80 |

0.1 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 66C |

75~105 |

0.1 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 67C |

95~155 |

0.2 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 68C |

145~205 |

0.2 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 69C |

195~305 |

0.5 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 70C |

295~405 |

0.5 |

Rod |

379±5 |

7~8 |

Total Immersion |

|

ASTM 71C |

-37~21 |

0.5 |

Rod |

355±5 |

6~7 |

76 |

|

ASTM 72C |

-19.4~-16.6 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 73C |

-41.4~-38.6 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 74C |

-55.4~-52.6 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 82C |

-15~105 |

1 |

Rod |

162±3 |

6~7 |

30 |

|

ASTM 83C |

15~75 |

1 |

Rod |

171±3 |

6~7 |

40 |

|

ASTM 84C |

25~80 |

1 |

Rod |

400 |

6~7 |

|

|

ASTM 85C |

40~150 |

1 |

Rod |

340 |

6~7 |

|

|

ASTM 86C |

95~175 |

1 |

Rod |

195±5 |

6~7 |

35 |

|

ASTM 87C |

150~205 |

1 |

Rod |

195±5 |

6~7 |

40 |

|

ASTM 88C |

10~200 |

1 |

Rod |

290±5 |

6~7 |

57 |

|

ASTM 89C |

-20~10 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 90C |

0~30 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 91C |

20~50 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 92C |

40~70 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 93C |

60~90 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 94C |

80~110 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 95C |

100~130 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 96C |

120~150 |

0.1 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 97C |

-18~49 |

0.5 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 98C |

16~82 |

0.5 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 99C |

-50~5 |

0.2 |

Rod |

302.5±2.5 |

6.5~8 |

35 |

|

ASTM 100C |

145~205 |

0.2 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 101C |

195~305 |

0.5 |

Rod |

370±5 |

6~7 |

76 |

|

ASTM 102C |

123~177 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 103C |

148~202 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 104C |

173~227 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 105C |

198~252 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 106C |

223~277 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 107C |

248~302 |

0.2 |

Rod |

395±5 |

6~8 |

100 |

|

ASTM 110C |

133.6~136.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 111C |

170~250 |

0.2 |

Rod |

395±5 |

6~7 |

100 |

|

ASTM 112C |

4~6 |

0.02 |

Rod |

215±5 |

6~7.5 |

Total Immersion |

|

ASTM 113C |

-1~175 |

0.5 |

Rod |

405±5 |

6~8 |

Total Immersion |

|

ASTM 114C |

-80~20 |

0.5 |

Rod |

300±5 |

6~8 |

Total Immersion |

|

ASTM 116C |

18.9~25.1 |

0.01 |

Rod |

609±5 |

7~8.2 |

Total Immersion |

|

ASTM 117C |

23.9~30.1 |

0.01 |

Rod |

609±5 |

7~8.2 |

Total Immersion |

|

ASTM 118C |

28.6~31.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 119C |

-38.3~-30 |

0.1 |

Rod |

420±5 |

6~7 |

100 |

|

ASTM 120C |

38.6~41.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 121C |

98.6~101.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 122C |

-45~-35 |

0.1 |

Rod |

400±5 |

5.5~8 |

Total Immersion |

|

ASTM 123C |

-35~-25 |

0.1 |

Rod |

400±5 |

5.5~8 |

Total Immersion |

|

ASTM 124C |

-25~-15 |

0.1 |

Rod |

400±5 |

5.5~8 |

Total Immersion |

|

ASTM 125C |

-15~-5 |

0.1 |

Rod |

300±5 |

5.5~8 |

Total Immersion |

|

ASTM 126C |

-27.4~-24.6 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 127C |

-21.4~-18.6 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 128C |

-1.4~1.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 129C |

91.6~94.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 130C |

-7~105 |

0.5 |

Rod |

302.5±2.5 |

6.9~7.9 |

Total Immersion |

|

ASTM 132C |

148.6~151.4 |

0.05 |

Rod |

305±5 |

6~8 |

Total Immersion |

|

ASTM 133C |

-38~2 |

0.1 |

Rod |

379±5 |

7~8 |

76 |

|

ASTM 134C |

144~156 |

0.2 |

Rod |

270±10 |

5~8 |

100 |

|

ASTM 135C |

38~93 |

1 |

Rod |

171±3 |

6~7 |

40 |

|

ASTM 136C |

-20~60 |

0.2 |

Rod |

290±5 |

6~8 |

Total Immersion |

|

ASTM 137C |

80~100 |

0.1 |

Rod |

255±5 |

5~8 |

76 |

Packaging of Industrial Glass Thermometer:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price