- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

LWC Copper Tube Coil for Transformer Components

Grade: C12200, C10200

Outside diameter: 4mm - 22.3mm

Thickness: 0.3mm - 1.5mm

Coil weight: customized

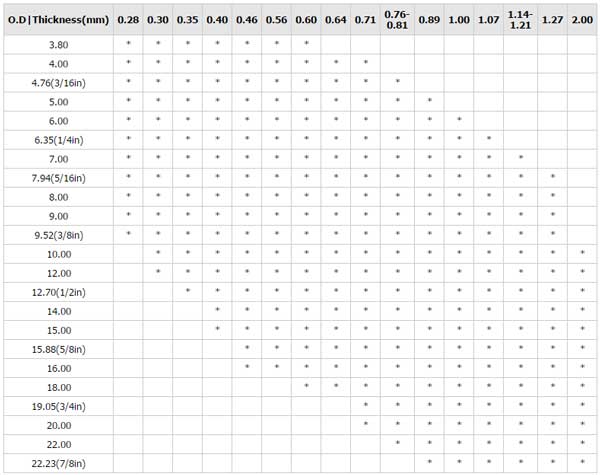

Specifications of LWC Copper Tube Coil for Transformer Components:

LWC Copper Tubes feature minimum copper content of 99.9% as per IS-191 and are available in Forged / Hot Rolled / Extruded as well as Cold worked finish in different dimensions and specifications. These are also available in hard, half-hard as well as soft conditions. As the tubes comprise DE-oxidized copper, it is not affected through reducing atmosphere and is well suited for welding and brazing applications.

General Properties:

1) Grade: C11000, C12200, C10200

2) Outside diameter: 4mm - 25.4mm

3) Thickness: 0.28mm - 2.0mm

4) Coil weight: 80kg - 100kg - 150kg - 200kg - 250kg - 300kg – 500kg

5) Temper:soft, half hard soft, half hard, hard

6) Standard : ASTM B-280, EN-12735, JISH-3300

7) Material: Phosphorus DE-oxidized Copper and Oxygen Free Copper

Grade of LWC copper tube coil:

1) Phosphorus Deoxidized Copper

2) Oxygen Free Copper

3) UNS C12200, C10200

Level Wound Copper Tube Coil for reference only

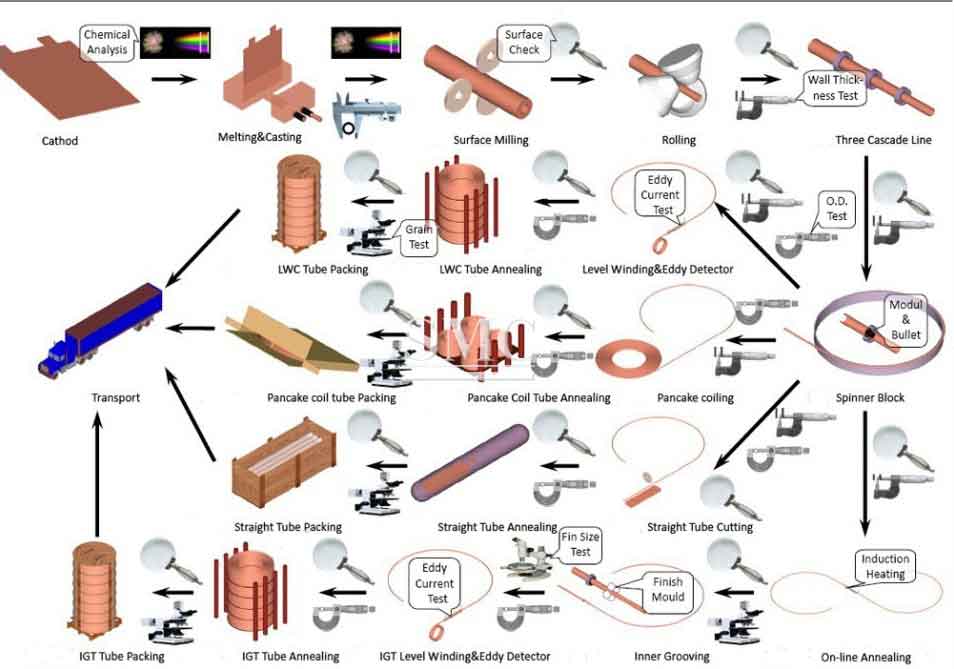

Manufacturing of LWC Copper Tube Coil

Packaging of LWC Copper Tube Coil

SMC Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) SMC Standard

2) Customization

Applications of Level Wound Copper Tube Coil:

1) Air conditioner and refrigerator

2) Water tube service & distribution

3) Handling of fire protection, solar, fuel/fuel oil

4) Handling of natural gas, liquefied petroleum (LP) gas

5) Handling of HVAC, drain applications

6) Handling of waste, vent piping needs

7) Re-drawing use

8) Heat exchange use

9) Gas services for heating and cooking

10) Oil services for heating

11) Chilled water and refrigeration

12) Fire sprinkler systems

13) Air conditioning

14) Handling of steam

15) Medical gases

16) Pneumatic

17) Hydraulics

here

for

price