- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

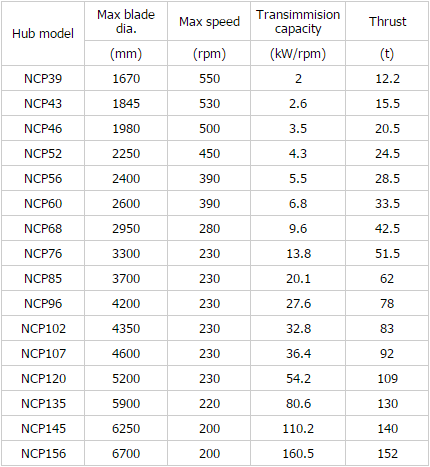

NCP Series Controllable Pitch

Material: Copper

Certification: ISO9001:2000

Blades: 4

Diameter (mm): 1120-6700mm

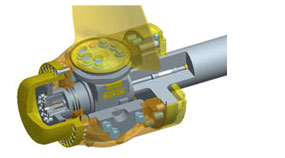

To meet the harsh ocean environment, NGC engineers take full consideration of reliabilities during the hydrodynamic calculation, structural design and material selection, which make our controllable pitch propellers are featured with good reliability, simple configuration and maintenance friendly, etc. The hub is designed with large diameter servo piston, and the hydraulic force of the piston works on the yoke, so as to decrease the work oil pressure required by the hydraulic system.

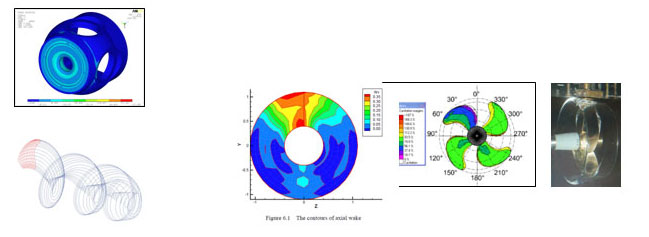

Combining the test to the propeller design, we apply the large skew propeller and optimal disc ratio solutions to lower down the cavitations and vibration of the propeller, in this way, not only the navigation speed and towing force can be satisfied, but also the operation performance and economical efficiency of the ship is improved.

During the shaft line design, the engineers take account of the negative influence to the shaft strength, vibration and alignment caused by the bending stress load change, propeller stress, gear meshing load and the bending stress of main engine crank shaft, and the calculation result fits more with real work condition.

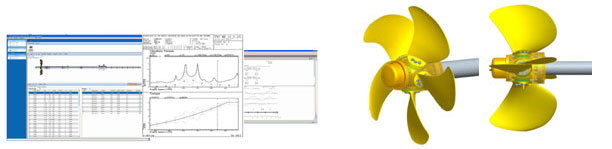

During the navigation, if the feathering CPP does not work, the blades can be adjusted to the downstream condition to decrease the resistance effectively.

NCP series controllable pitch propeller diagram:

Hydraulic system of NCP series CPP is composed of OD box and hydraulic power pack, and the power pack is split into two types: single pump and double pump. The single pump power pack is the standby, main pump is the pump driven by the gearbox. There are two sets of electric pumps in double pump power pack, which can transform between one another automatically.

The OD box can be mounted in front of the gearbox or on the shaft line. These two arrangements of gearboxes are attested to be very reliable and flexible to maneuver.

here

for

price