- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Turnbuckle

Material: Stainless Steel 316 or Carbon Steel

Size: 1/4 inch 4 inch - 2-3/4×24 inch

Turnbuckles are the device for tightening a rod or wire rope. Its parts are sleeves with a screwed connection at one end and a swivel at the other. The ends are hook, eye, and clevis. The turn-buckle can be connected at any convenient place in the rod or rope, and several may be used in series if required.

-

Stainless Steel - from small turnbuckles to larger assemblies 316L stainless turnbuckles offer high corrosion resistance and durability with standard UNC threading to interchange turnbuckle hardware. Stainless steel turnbuckles offer the highest resistance to high chloride or high moisture environments.

-

Pipe - pipe turnbuckles are a version of stainless steel manufacturing but the body of the turnbuckle is enclosed in stainless steel pipe for cosmetic reasons such as wire railings so that threads are not visible unlike standard turnbuckle hardware. UNC threaded so the fittings can be interchanged with standard turnbuckle fittings.

-

Galvanized Turnbuckles - hot dip galvanized steel for durability, resistance to corrosives, and weather resistance. Made for in-line or straight pull applications only.

-

1. Mining

2. Marine Application

3. Crane Operation

4. Electronic power

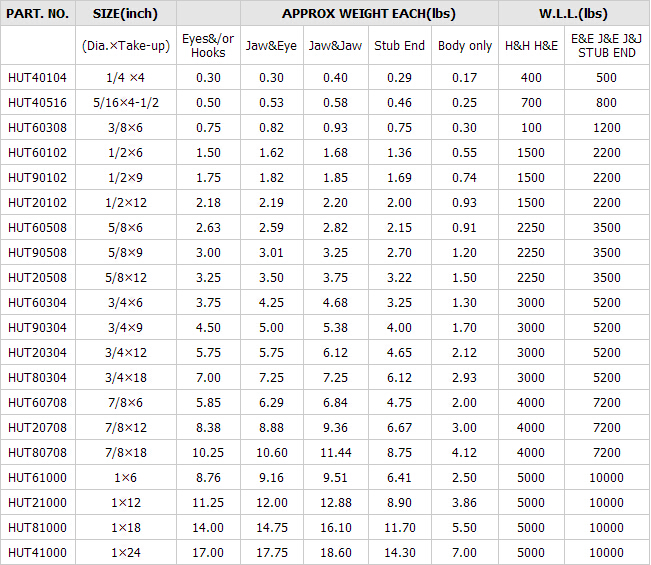

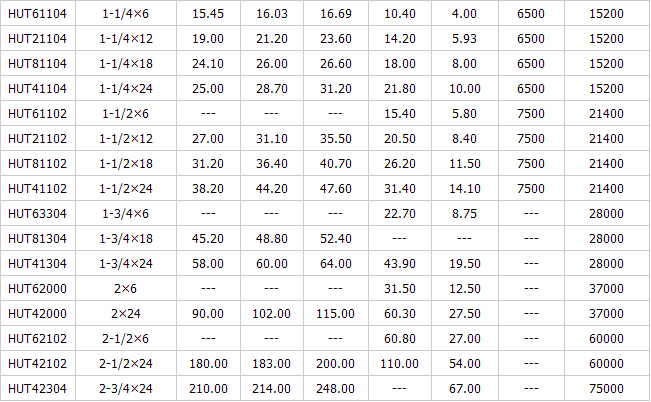

Data of Turnbuckle:

The table below shows standard sizes. Other sizes are available on request and can be manufactured to order.

Option of Turnbuckle:

However, the most prevalent choice is a sleeve with screwed connections of opposite hands (left and right) at each end so that by turning the sleeve, the connected parts will be drawn together, taking up slack and producing tension.

•Deck Toggle - a "T" shaped bar sits inside a mounting bracket with holes on either side. This configuration allows the turnbuckle assemblies to rotate 180 degrees within the mounting bracket. This type of fitting is often used to attach to deck posts.

•Drop Pin - these turnbuckle tie downs have a rotating pin on the end that flips flat into the body of the pin to thread through a hole and then can be extended perpendicular to the body for a secure hold. This end fitting offers an excellent clean look. •Eye - solid loop end for wire rope turnbuckle with no vulnerable connection points to allow cable to slip through. Elongated eye version minimizes stress on the turnbuckle component.

•Fork or Jaw -rigging turnbuckles with wishbone shaped anchor point fitted with a nut and bolt or pin and cotter turnbuckle assembly, this type of fitting is ideal for situations where the anchor point is fixed and will not work with an eye or the anchor point needs to be secured from slipping off the fitting.

•Hook - stainless turnbuckle ending in an open hook. Hooked ends of the turnbuckle may open the same direction or in opposite directions depending on your rigging requirements. This fitting offers the quickest option for attachment and release. •Lag Screw - the threaded screw end of these turnbuckles allow for permanent, secure attachment to your anchor points.

•Stub End - these rigging turnbuckles are used where a connecting point is not needed like most turnbuckle ends, but rather are used to separate or push apart objects. •Swage Stud - swage stud turn buckle fittings offer a solid corrosion resistant end point that is threaded to accept wires directly into the fitting and swaged to secure them permanently.

•Threaded Rod - turnbuckle hardware end fitting with standard threads that easily form a direct connection to a post or other mounting surface.

here

for

price