- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

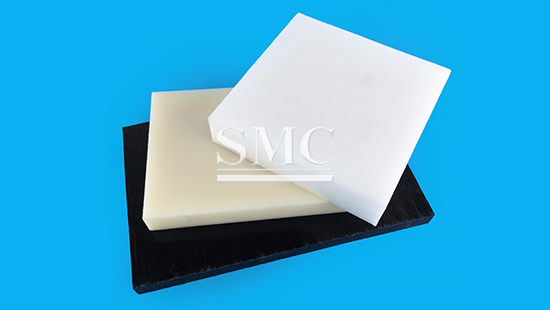

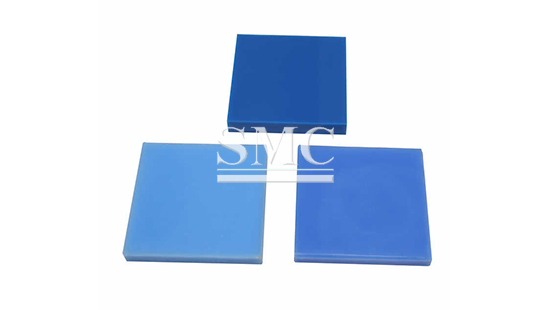

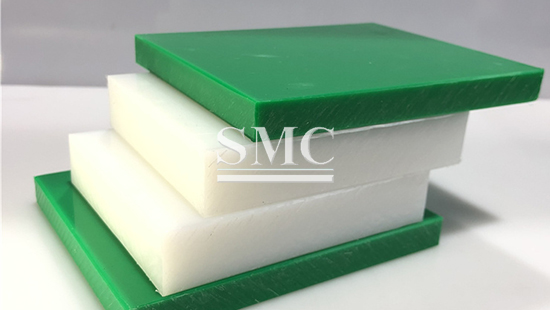

POM Sheet/ Plate

Material: Paraformaldehyde Copolymer & Homopolymer

Thickness: 1-200mm

Size: 620 x 1220mm or Customized

Shanghai Metal Corporation is a leading manufacturer and supplier of POM (Paraformaldehyde Copolymer & Homopolymer) sheets. POM is a thermoplastic engineering plastics with high melting point and high crystallinity, a yellowish or white crystalline polymer with smooth and dense surface. According to the chemical structure of molecular chain, it can be divided into polyformaldehyde copolymer and polyformaldehyde homopolymer.

Shanghai Metal Corporation has a complete quality control system. Our POM sheets are made of CELANESE brand raw material, have excellent mechanical properties, after full annealing, the stress relieving is eliminated and the dimensional stability is high. In order to ensure zero defect and zero complaints, we monitor and control every link from raw materials to production, to the warehousing and shipment of finished products. The inspection includes the appearance data of the product, including the length, width, thickness, weight, flatness, hardness, surface and cross section. In addition, according to customer requirements and application conditions, we have well-equipped facilities to test the physical and chemical properties of the products, such as the impact strength, aging resistance, flame retardancy, etc.

If you want to know more about our products or POM sheet price, please feel free to contact us. We will reply you within 24 hours.

|

Physical Property of POM Sheet |

||||

|

Property |

Standard |

Unit |

Value |

|

|

Physical Properties |

||||

|

Density |

ISO 1183 |

g/cm3 |

1.42 |

|

|

Water absorption |

ISO 062 |

% |

0.7 |

|

|

Mechanical Properties |

||||

|

Tensile Strength at yield |

ISO 527 |

Mpa |

63 |

|

|

Tensile Strength at break |

ISO 527 |

Mpa |

/ |

|

|

Elongation at break |

ISO 527 |

% |

>30 |

|

|

Modulus of elasticity after tensile test at 23℃ |

ISO 527 |

Mpa |

/ |

|

|

Modulus of elasticity after flexural test at 23℃ |

ISO 178 |

Mpa |

2600 |

|

|

Firction coefficient |

DIN 53375 |

|

0.35 |

|

|

Charpy impact strength |

ISO 179/1EA |

kj/m2 |

7 |

|

|

Hardness-Rockwell |

ISO 2039-2 |

|

135 |

|

|

Hardnes-Shore D |

DIN 55305 |

|

85 |

|

|

Thermal Properties |

||||

|

Heat deflection temperature-HDT/A |

ISO 75-2 |

℃ |

110 |

|

|

Max. service temperature-short term |

|

℃ |

140 |

|

|

Max. service temperature-long term |

|

℃ |

/ |

|

|

Thermal conductivity at 23℃ |

DIN11359 |

W/(k*m) |

0.31 |

|

|

Coefficient of linearthermal expansion |

DIN11359 |

10-4*k-1 |

1.1 |

|

|

Electrical Properties |

||||

|

Dielectric constant at 1MHz |

IEC 60250 |

106HZ |

3.8 |

|

|

Dielectric loss factor at 1MHz |

IEC 60250 |

106HZ |

0.005 |

|

|

Surface resisivity |

IEC 60093 |

Ohm (Ω) |

106-109 |

|

|

Volume resisivity |

IEC 60093 |

Ohm (Ω) |

106-109 |

|

|

Dielectirc stregnth |

IEC 60243-1 |

KV/mm |

>37 |

|

|

Miscellaneous Data |

||||

|

Flammability |

UL94 |

|

HB |

|

|

NOTE: The information contained herein are typical values intended for reference by our factory and comparison purpose only. They should not be used as a basis for design specifications or qualtity control. SMC will not provide any legally binding guarantee of certain properties nor any suitability. |

||||

Packaging

1. Trimmed/Untrimmed, with PVC edges.

2. Covered by PE film or craft paper with logo.

3. Packed in wooden case.

here

for

price