- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

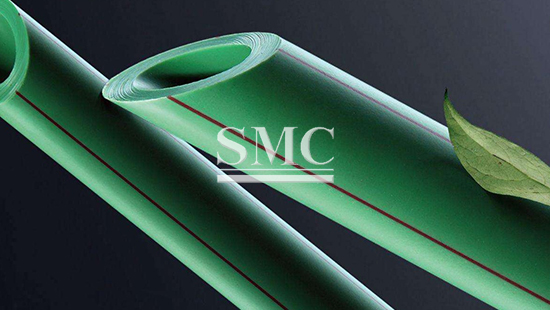

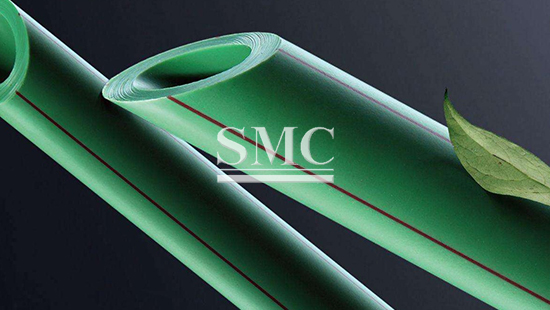

PPR Pipe

Material: Polypropylene Random

Color: Green mainly

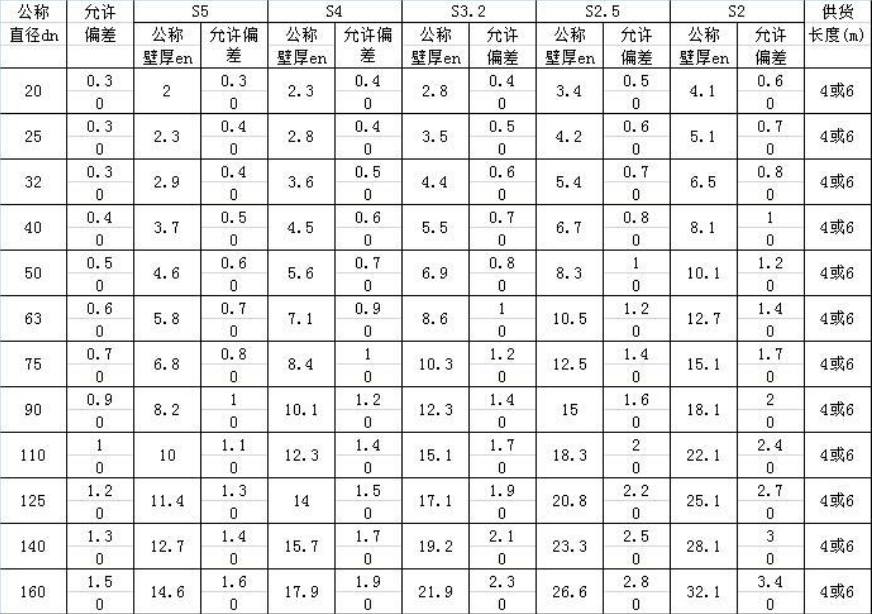

Standard: GB/T18742.2-2002

Length: Customized

Shanghai Metal Corporation is a leading PPR Pipe manufacturer and supplier.

PPR is the acronym for Polypropylene-Random. Commonly known as three-type polypropylene. PPR pipe is the replacement product of UPVC water supply pipe, aluminum-plastic pipe, PE pipe, PE-X pipe and PE-RT pipe. Because it uses random copolymerization technology, the strength and high temperature resistance of polypropylene are well guaranteed, thus becoming the main force of water pipe materials.

If you want to know more about our PPR Pipe or get price please feel free to contact us, we will reply you within 24 hours.

Pipe Installation of PPR Pipe:

Cutting: Cut the pipe, and use a pipe cutter to cut it vertically. If there is no pipe cutter, use other tools to cut the pipe. After cutting, the cutting head should be cleaned.

Heating: When the fusion splicer is heated to the working indicator green light, the pipes and fittings are simultaneously pushed into the melter and heated to 5-7 seconds.

Connection: The heated pipe and fittings are pushed vertically and maintained for more than 10-12 seconds. Do not push too hard when pushing to prevent the pipe head from bending.

Pressure test: In order to ensure the quality of the welding, the pressure test shall be conducted after 24 hours of pipeline connection.

Acceptance: Before the pipeline project is completed and delivered for using, it must be pressure tested for acceptance before it can be sealed for use.

Insulation: Insulation and sun protection measures should be taken when laying outdoors or exposed to freezing indoors.

Packing of PPR Pipe:

Precautions during hot melt:

1. Before heat welding, make sure the pipe and pipe fittings are clean.

2. Pipes and fittings are pushed into the welder mold with both hands.

3. When the pipe and pipe fittings are overheated, the pipe will be deformed in the pipe fittings, and water leakage may occur.

here

for

price