- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

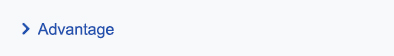

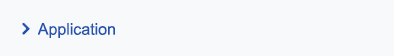

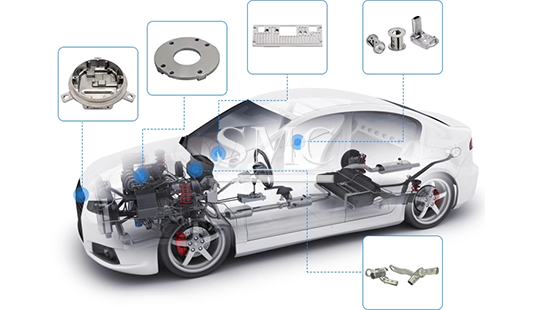

Aluminum Casting Part/ Aluminum Die Casting

Material: Aluminum alloy ADC12, ADC10, A360, A380, A356, A413, LM20, LM24, etc.

Part Weight: from 3g --- 20kg or Customized

Thickness: 0.4mm-20mm or Customized

Deep Processing: CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling

Shanghai Metal Corporation is a leading manufacturer and supplier of aluminum casting parts in China, who is engaged in design and produce aluminum alloy die casting, gravity casting, aluminum profiles, and CNC machining.

We provide all-round production services from the design and development of mould to the forming and post-processing of casting products and surface treatment. The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on.

With over more than 20 years’ experience about development and manufacture management, we can support the DFM report, mold flow analysis and mold design service. Our company's production workshop consists of mould department, die-casting department, processing department, CNC department, paint department, etc. If needed, we can also make exporting die casting mold for customer.

If you want to know more about our aluminum casting parts, aluminum die casting product or other related products, please feel free to contact us, we will reply you within 24 hours.

-

-

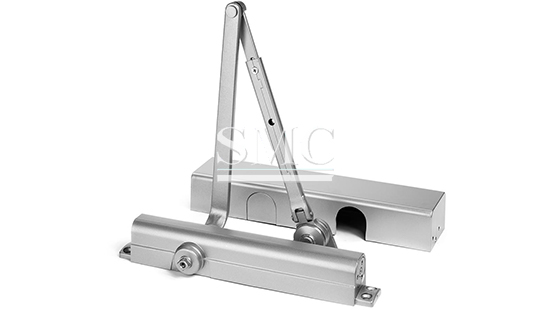

1) High load capacity and accuracy

2) High density and harness

3) Wear and corrosion resistance

4) Precision reference point correction

5) It saves metal materials and labor costs

6) High thermal conductivity

7) Has good fluidity and plasticity

-

1) Automobile and motorcycle accessories

2) Lamp accessories

3) Medical and health care

4) Consumer electronics

5) Hardware parts

6) Communication equipment

-

-

-

1) Sign Drawing (Generally clients provide the drawing or samples)

2) Make Mould

3) Die Casting (Aluminium or Aluminium Alloys)

4) Precision Machining (Burring, Lathe, Milling, etc)

5) Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing

6) Inspection and Packing

1. Machining Equipment: 260 CNC Lathe, 200 Auto Lathe,10 CNC Tapping Center,2 MAZAK five axis CNC, etc

2. Surface Treatment: Chrome Plating, Zinc Plating, Blackening, Nickel plating, Electrophoresis, Anodization, Brushing, Polishing, Blacken, Powder coating, Sandblasting, de-buring, Passivation, etc.

3. Testing Facility: Coordinate Measuring Machine, Projector, Roughness Tester, Hardness Tester, Concentricity Tester, Tool Microscope, Digimatic Micrometer, Inside Micrometer, Dial Indicator, Go No Go Gauge, Dialgage, Eletronic, Digital Display Caliper, Automatic Height Gauge, Precision Level 2 Detector, Precision Block Gauge,00 Levels Of Marble Platform/Ring Gague, etc.

.png)

.png)

1. Plastic bag with the pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

4. Deliver out by sea or air.

5. Or according to customers' requirements.

.png)

.png)

here

for

price

.png)

.png)

.jpg)

.png)