- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Carbon Steel Pipe/Tube for Oil Drill Pipe

Standard: ASTM A106, P235GH, EN10210, ASTM A572, AS/NZS 1163, AWWA C210, AWWA C200, etc.

Process Method: hot rolling, cold drawn or welded.

Modern drill pipe is made from the welding of at least three separate pieces:

the box tool joint, the pin tool joint and the tube.

The green tubes are received by the drill pipe manufacturer from the steel mill.

The ends of the tubes are then upset to increase the cross sectional area of the ends.

The tube end may be externally upset (EU), internally upset (IU), or internally and externally upset (IEU).

Standard max upset dimensions are specified in API 5DP, but the exact dimensions of the upset

are proprietary to the manufacturer.

After upsetting, the tube then goes through a heat treating process.

Drill pipe steel is commonly quenched and tempered to achieve high yield strengths

(135 ksi is a common tube yield strength).

Packaging of Carbon Steel Pipe/Tube

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

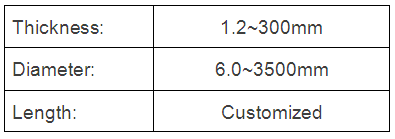

We provide wide range of sizes for different applications:

Surface Treatment: Oiling, Painting, Galvanizing, Anti-corrosion, Polished, etc.

If you have any requests or question, please contact us for more details.

here

for

price