- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Chrome Plated Round Bar/Piston Rod/Linear Shaft

Shanghai Metal Corporation is a leading Chrome Plated Round Bar/Piston Rod/Linear Shaft manufacturer and supplier.

The surface of Chrome Plated Round Bar/Piston Rod/Linear Shaft is polished by special grinding and hard chromium plating technology, and then by mirror polishing. It is wear-resistant and corrosion-resistant. It is suitable for all kinds of hydraulic cylinders, optical axles, piston rods, packaging, woodworking, textile, printing and dyeing machinery, die-casting machine, injection molding machine, and other mechanical guide rods, Jack rods, etc.

If you want to know more about our Chrome Plated Round Bar/Piston Rod/Linear Shaft please feel free to contact us, we will reply you within 24 hours.

Technical information of Chrome Plated Round Bar/Piston Rod/Linear Shaft:

2.1 CHEMICAL COMPOSITION

|

Material |

C% |

Mn% |

Si% |

S% |

P% |

V% |

Cr% |

|

CK45 |

0.42-0.50 |

0.50-0.80 |

≤0.04 |

≤0.035 |

0.035 |

|

≤ 0.25 |

|

ST52 |

≤0.22 |

≤1.6 |

≤0.55 |

≤0.04 |

≤0.04 |

|

|

|

20MnV6 |

0.16-0.22 |

1.30-1.70 |

0.10-0.50 |

≤0.035 |

≤0.035 |

0.10-0.20 |

≤0.30 |

|

42CrMo4 |

0.38-0.45 |

0.60-0.90 |

0.15-0.40 |

≤0.035 |

≤0.035 |

0.07-0.12 |

0.90-1.20 |

|

40Cr |

0.37-0.45 |

0.50-0.80 |

0.17-0.37 |

≤0.035 |

≤0.035 |

|

0.80-1.10 |

2.2 MECHANICAL PROPERTIES

|

Material |

T.S N/MM2 |

Y.S N/MM2 |

E%(MIN) |

CHARPY |

CONDITION |

|

CK45 |

610 |

355 |

15 |

>41J |

NORMALIZE |

|

CK45 |

800 |

630 |

20 |

>41J |

Q + T |

|

ST52 |

500 |

355 |

22 |

|

NORMALIZE |

|

20MnV6 |

750 |

590 |

12 |

>40J |

NORMALIZE |

|

42CrMo4 |

980 |

850 |

14 |

>47J |

Q + T |

|

40Cr |

1000 |

800 |

10 |

|

Q + T |

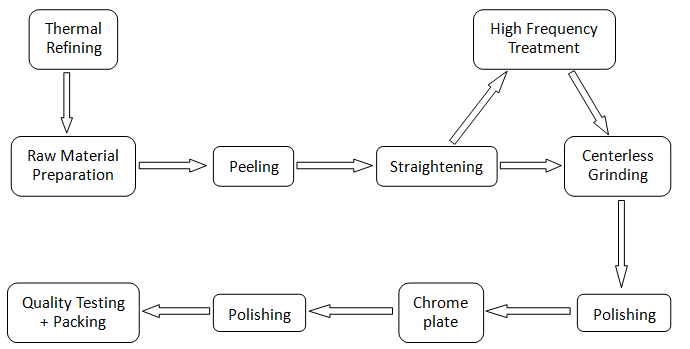

2.3 WORK FLOW

Packaging of Chrome Plated Bar/Linear shaft (Hard shaft/Flexible shaft):

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

A. Wooden Case

B. Carton Packing

C. Straw Rope

D. Air Cushion (film) Bag

The linear shaft can be divided into hard shaft and soft shaft according to the hardness of heat treatment.

Hard shaft is quenched by high frequency quenching on surface, and its surface hardness is generally about HRC60. Hard shafts are suitable for use with linear bearings.

Flexible shaft is not quenched by high frequency, the hardness is generally HB200~300, equivalent to HRC25 or so. Soft shafts are not suitable for use with linear bearings.

here

for

price