- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Cold Rolled Steel Coil for Food Can

Thickness: 0.18mm - 3.5mm

Width: 600/1000/1250/1500mm

Coil ID: 508mm/610mm

Specifications of Cold Rolled Steel Coil:

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing, etc.

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002, JIS G3445

3) Thickness: 0.18mm - 3.5mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

5) Coil ID: 508mm/610mm or per customer's request

Cold rolling is used to further treat hot rolled steel sheet to increase its strength and its strength-to-weight ratio

and enable it to hold tighter tolerances during fabricating and machining. In addition, cold rolling is used to smooth

and finish the surface of hot rolled steel. The processes used to improve the surface finish

and to size the cold rolled sheet more precisely include chemical or mechanical descaling and cold rolling or polishing.

When the protective oxide surface normally found on hot rolled sheets is removed during cold rolling,

it leaves a surface finish that is considered perishable. Great care must be taken during handling, storage,

and shipment to preserve and protect this smooth, slick, surface.

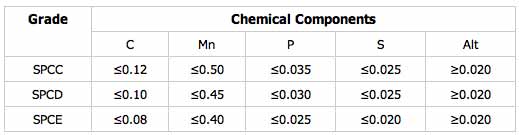

Chemical Components:

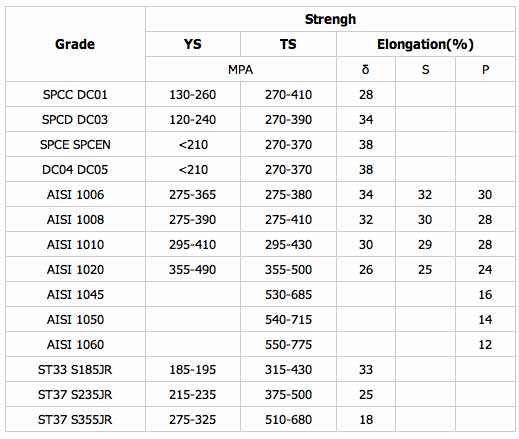

Mechanical Properties:

Packaging of Cold Rolled Steel Coil

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Cold Rolled Steel Coil:

Cold rolled steel sheet is used for engineered products that require tight tolerances and coated surfaces. These include:

1) Appliances, including stoves, ovens, refrigerators, washers, dryers and small appliances

2) Exposed automotive and aircraft components

3) Building frames

4) Deep-drawn shells

5) Stamped parts

here

for

price