- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Stainless Steel Sprocket

Color:nickel white and customed

Standard:DIN GB JIS AISI

Grade:SUS201, SUS304, SUS316 etc.

Shanghai Metal Corporation is a leading Stainess Steel Sprocket manufacturer and supplier.

As a common transmission force device, the stainless steel chain is designed to reduce friction by the “chain” design of the hyperbolic arc. It is used in places where the power is relatively large and the running speed is relatively slow, which is obviously superior to the belt drive, for example. Tanks, pneumatic compressors, etc., but the transmission speed can not be too fast, because the chain is not as flexible as the belt. Stainless steel chains are particularly suitable for cleaning or in demanding areas where certain chemicals are required, as well as in high and low temperature applications.

If you want to know more about our Stainess Steel Fitting products or Stainess Steel Sprocket price please feel free to contact us, we will reply you within 24 hours.

Production Detail of Stainess Steel Sprocket:

We manufacture various chain sprocket and have strong processing capacity to ensure good quality and competitive price.

1. American Standard, European Standards, Japanese Standards

2. Pilot bore, finished bore, taper bore and special bore available

3. Bright surface and high precision

4. Advanced heat treatment and surface treatment crafts

5. Better quality and competitive price.

6. Material C45(1045), low carbon steel, 40Cr, 20CrMnTi, stainless steel such as SS316L, SS316, SS304, SS420, copper etc. available

7. Standard sea worthy package to Europe and American

8. High speed digital gear hobbing machines to guarantee the teeths quality

9. Corrosion resistance treatment available

10. Control on tolerance and easy to install

11. Good material and good treatment to make sure long life span

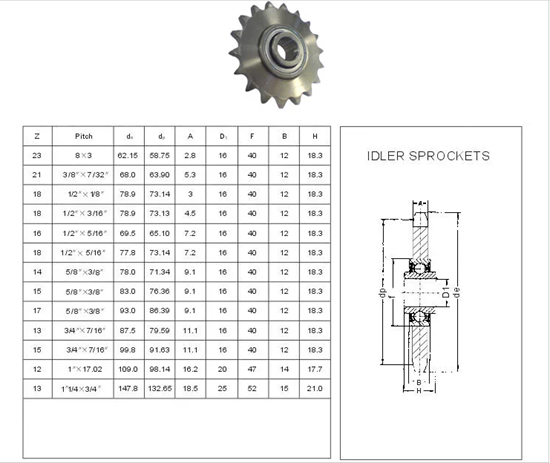

Technical Information of Stainess Steel Sprocket:

Manufacturing method:Forged and then machined, hobbed, if need can also weld

Heat treatment:High frequency quenching and so on

Surface treatment:Oxide black, Galvanized, Nickel plated, Chrome plated, Sandblasting, Painted and so on

Idler Sprockets: Ball Bearing Idler Sprockets have sealed ball bearings with extended inner race and setscrews for securing to the shaft.

Projection From Centerline –Due to dimensional variation among bearing manufacturers this dimension may vary slightly when different brands of bearings are used. If you have a critical application please call for specific dimensions.

Inner Race projection has 2 set screws on long side to secure bearing to shaft.

“Basic Dynamic Ratings”calculated according to AFBMA standard for “Long Rating And Fatigue Life For Ball Bearings”

Accurately machined, medium carbon steel sprockets and precision ground ball bearings are assembled to provide a heavy duty idler for the most severe conditions. The bearings are pre-lubricated and sealed to retain grease and exclude dirt and moisture. They are not re-lubricatable. The extended inner race with setscrew allows fastening to a pin or shaft without collars or spacing devices. It also provides clearance for the chain when bolting the sprocket directly to a frame member or tensioning device. A small sprocket for close quarters and a larger one for heavier service is provided in each pitch. If sizes other than those listed are required, please inquire for quotation.

Packaging of Stainess Steel Sprocket:

Packing Details :plywood case + Steel pallet

We can also customize the packing method according to customers' needs.

Suitable for seaway transportation

More of Stainess Steel Sprocket:

Sprocket application: widely used in chemical industry, textile machinery, food processing, instrumentation, petroleum and other industries such as mechanical transmission

Q1:What is your terms of payment?

A: T/T 30% as deposit, and 70% after recived the cope of the B/L.

Q2:What is your terms of delivery?

A: L/C.T/T.

here

for

price