- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Steel Fiber

Length to diameter ratio:30~100

Shanghai Metal Corporation is a leading manufacturer and supplier of steel fiber .

Steel fiber refers to the ratio of length to diameter is 40 to 80mm. (The ratio of fiber length to diameter) made by cutting thin steel wire, cold-rolled strip, steel ingot milling, or rapid condensation of molten steel. When the fiber section is non-circular, the equivalent section circle is converted The diameter of the area). The properties of steel fibers produced by different preparation methods are different. Although steel fiber has not been around for a long time, its application has become more and more extensive, and increasingly types.

We can produce many types of steel fiber meeting your requirements.

Shanghai Metal Corporation is a professional manufacturer and supplier of steel fiber.We also supply stainless steel fiber, ceramic fiber.

If you want to know more about our steel fiber product or other material price, please feel free to contact us, we will reply you within 24 hours.

Technical Information of Steel Fiber:

There are four main manufacturing methods for steel fiber used in steel fiber concrete

1. Wire cutting method

Generally, cold drawn steel wires with a small diameter of 0.4-0.8mm are used as raw materials, and the steel wires are cut into short fibers according to the specified length. The tensile strength of steel fiber produced by this method is much higher than that of steel fiber processed by other methods, reaching 1000-2000MPa.

2. Thin plate shearing method

The sheet shearing method is a method of cutting cold-rolled sheet steel into steel fibers.

Before cutting, use a special small slitting machine to cut the thin cold-rolled coils into strip coils. The width of the strip coils is the same as the length of the steel fiber, and then the strip coils are continuously fed into the rotary cutter or ordinary punching machine for cutting. , The axis of the rotary tool and the feed direction of the sheet are perpendicular to each other.

3. Steel ingot milling method

The raw material used is steel fiber made of thick steel plate or steel ingot, which is cut with a rotating flat-edged iron knife. When cutting, the steel fiber will produce very plastic deformation and twist between the shafts, which can increase the bonding force with concrete and other substrates.

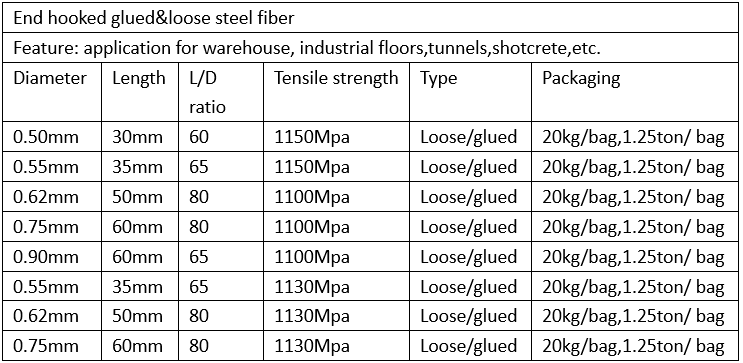

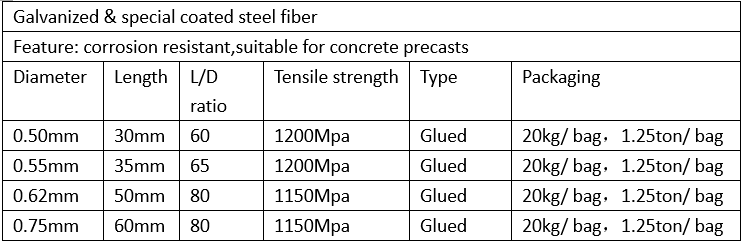

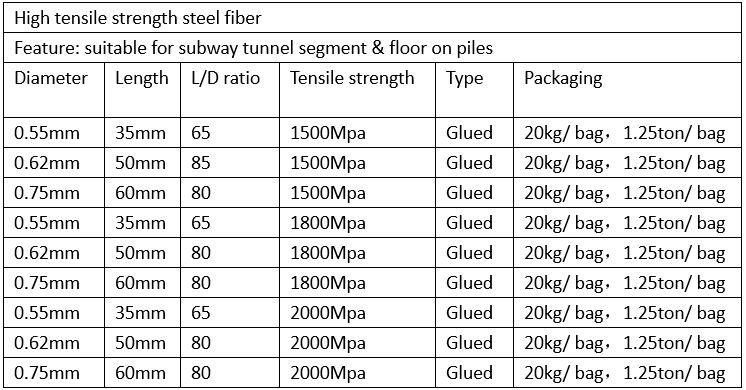

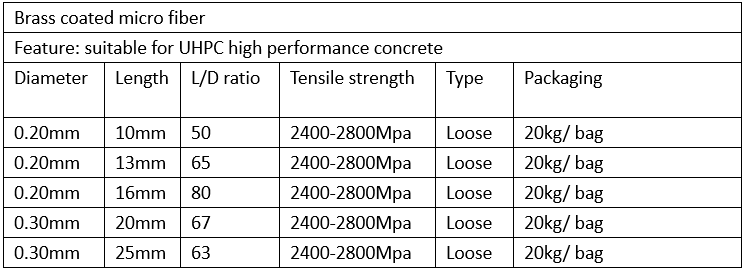

Specification of Steel Fiber:

If you are interested in steel fiber, please feel free to let us know your require of color, size and shapes.

Packaging of steel fiber:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Advantages:

1. Reinforcing concrete with Steel fibers results in durable concrete with a high flexural and fatigue flexural strength, improved abrasion, spalling and impact resistance.

2. The elimination of conventional reinforcement, and in some cases the reduction in section thickness can contribute to some significant productivity improvements. Steel fibers can deliver significant cost savings, together with reduced material volume, more rapid construction and reduced labour costs.

3. The random distribution of Steel fibers in concrete ensures that crack free stress accommodation occurs throughout the concrete. Thus micro cracks are intercepted before they develop and impair the performance of the concrete.

4. Steel fibers are a far more economical design alternative.

Disadvantages:

1. Steel fibers will not float on the surface of a properly finished slab, however, rain damaged slabs allow both aggregate and fibers to be exposed and will present as aesthetically poor whilst maintaining structural soundness.

2. Fibers are capable of substituting reinforcement in all structural elements (including primary reinforcement), however, within each element there will be a point where the fibre alternative’s cost saving and design economies are diminished.

3. Strict control of concrete wastage must be monitored in order to keep it at a minimum. Wasted concrete means wasted fibers.

here

for

price