- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Steel Wire Rope/ Steel Cable

Material: High Carbon Steel, Alloy Steel, Stainless Steel, etc.

Application: Elevator, crane lifting, hanging basket, aircraft, marine, logging

Shanghai Metal Corporation is a professional manufacturer and supplier of Steel Wire Rope/ Steel Cable with high quality and reasonable price.

Wire rope is made of plaiting strands of wire – normally medium carbon steel – into a thick cable. The strands are formed around a core. The strands in wire ropes are made of wore twisted together. Strands with smaller diameter wires are less abrasion resistant and more fatigue resistant. Strands made with thicker length of wore are more abrasion resistant and less fatigue resistant. The strands are in turn twisted to form steel wire ropes of different sizes, depending on the desired strength of the steel wire rope.

Steel wire ropes are consumables which may be discarded when worn out. Steel wire ropes are used in mooring, towing and lifting systems.

If you want to know more about Steel Wire Rope/ Steel Cable price please feel free to contact us, we will reply you within 24 hours

The following abbreviations are commonly used to specify a wire rope:

|

Abbr. |

Description |

|

FC |

Fibre core |

|

FSWR |

Flexible steel wire rope |

|

FW |

Filler wire |

|

IWR |

Independent wire rope |

|

IWRC |

Independent wire rope core |

|

J |

Jute (fibre) |

|

LH |

Left hand lay |

|

LL |

Lang's lay |

|

NR |

Non-rotating |

|

OL |

Orcfnary lay |

|

RH |

Right hand lay |

|

S |

Seale |

|

SF |

Seale filler wire |

|

SW |

Seale Warrington |

|

SWL |

Safe working load |

|

TS |

Triangular strand |

|

W |

Warrington |

|

WF |

Warriflex |

|

WLL |

Waiting load limit |

|

WS |

Warrington Seale |

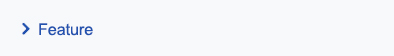

Different Cross-sectional Views of Special Wire Ropes:

|

8X19S+FC, 8xl9W+Fc, 8x25FI+Fc |

||||||||

|

Structure |

8xl9S+Fc |

8xl9W+Fc |

8x25Fi+Fc |

|||||

|

Nominal diameter |

Weight |

Minimum breaking force /kN |

||||||

|

mm |

kg/100m |

Dual Intensity /MPa |

Single Intensity /MPa |

|||||

|

1180/1770 |

1320/1620 |

1370/1770 |

1570/1770 |

1570 |

1620 |

1770 |

||

|

8.1 |

21.8 |

25.7 |

26.5 |

28.1 |

30.8 |

29.4 |

30.4 |

33.2 |

|

9 |

27.5 |

32.5 |

|

35.6 |

38.9 |

37.3 |

— |

42 |

|

9.5 |

30.7 |

36.2 |

37.3 |

39.7 |

43.6 |

41.5 |

42.8 |

46.8 |

|

10.1 |

34 |

40.1 |

41.3 |

44 |

48.1 |

46 |

47.5 |

51.9 |

|

11.1 |

41.1 |

48.6 |

50 |

53.2 |

58.1 |

55.7 |

57.4 |

62.8 |

|

12 |

49 |

57.8 |

59.5 |

63.3 |

69.2 |

66.2 |

68.4 |

74.7 |

|

12.7 |

54.8 |

64.7 |

66.6 |

70.9 |

77.5 |

74.2 |

76.6 |

83.6 |

|

13.1 |

57.5 |

67.8 |

69.8 |

74.3 |

81.2 |

77.7 |

80.2 |

87.6 |

|

14 |

66.6 |

78.7 |

81 |

86.1 |

94.2 |

90.2 |

93 |

102 |

|

14.3 |

69.5 |

82.1 |

|

— |

98.3 |

— |

— |

— |

|

15 |

76.5 |

90.3 |

— |

98.9 |

108 |

104 |

— |

117 |

|

16.1 |

87 |

103 |

106 |

113 |

123 |

118 |

122 |

133 |

|

17.5 |

104 |

123 |

— |

— |

147 |

— |

— |

— |

|

18 |

110 |

130 |

134 |

142 |

156 |

149 |

154 |

168 |

|

19.1 |

123 |

145 |

149 |

159 |

173 |

166 |

171 |

187 |

|

20 |

136 |

161 |

165 |

176 |

192 |

184 |

190 |

207 |

|

20.6 |

144 |

170 |

— |

— |

204 |

— |

— |

— |

|

22.1 |

165 |

194 |

200 |

213 |

233 |

223 |

230 |

251 |

|

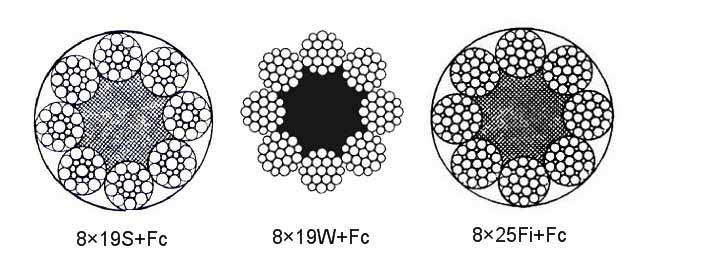

JIS Series of product structure—IWRC 6xFI(29)、IWRC 6xWS(31)、IWRC 6xWS(36) Breaking load |

|||

|

The implementation of this family of products Q/320202AABL01-2006 Enterprise Standard (JISG3525: 1998) |

|||

|

|

Steel Plug 29 Wire 6 Unit |

Steel Western Watts Unit 31 Wire 6 Unit |

Steel Western Watts 36 Wire 6 Unit |

|

Structure tag |

IWRC 6xFi(29) |

IWRC 6xWS(31) |

IWRC 6xWS(36) |

|

Nominal diameter |

Breaking load kN |

weight |

|

|

mm |

Smooth, galvanized |

kg/m |

|

|

|

B |

|

|

|

10 |

66.2 |

0.430 |

|

|

11.2 |

83 |

0.539 |

|

|

12.5 |

103 |

0.672 |

|

|

14 |

130 |

0.843 |

|

|

16 |

169 |

1.100 |

|

|

18 |

214 |

1.390 |

|

|

20 |

265 |

1.720 |

|

|

22.4 |

332 |

2.160 |

|

|

25 |

414 |

2.690 |

|

|

28 |

519 |

3.370 |

|

|

30 |

596 |

3.870 |

|

|

31.5 |

657 |

4.270 |

|

|

33.5 |

743 |

4.830 |

|

|

35.5 |

834 |

5.420 |

|

|

37.5 |

931 |

6.050 |

|

|

40 |

1060 |

6.880 |

|

|

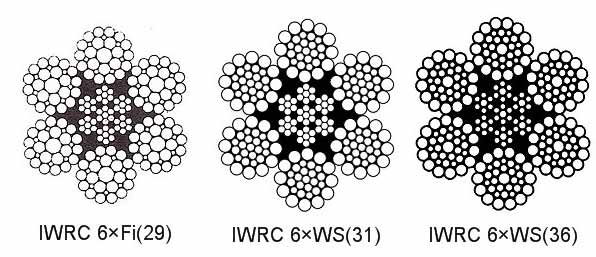

34x7+Fc, 34X7+IWS, 36x7+Fc, 36x7+IWS Mechanical Properties |

||||||||||||

|

Frame |

34x7+Fc |

34x7+IWS |

36x7+Fc |

36x7+IWS |

||||||||

|

Nominal wire rope diameter |

Reference weight |

Nominal tensile strength of steel wire rope/MPa |

||||||||||

|

mm |

kg/100m |

1570 |

1670 |

1770 |

1870 |

1960 |

||||||

|

|

|

Minimum pull rope breaking/kN |

||||||||||

|

|

Fiber Core |

Steel core |

Fiber Core |

Steel core |

Fiber Core |

Steel core |

Fiber Core |

Steel core |

Fiber Core |

Steel core |

Fiber Core |

Steel |

|

16 |

99.8 |

110 |

124 |

128 |

132 |

136 |

140 |

144 |

147 |

152 |

155 |

160 |

|

18 |

126 |

139 |

157 |

162 |

167 |

172 |

177 |

182 |

187 |

193 |

196 |

202 |

|

20 |

156 |

172 |

193 |

200 |

206 |

212 |

218 |

225 |

230 |

238 |

241 |

249 |

|

22 |

189 |

208 |

234 |

242 |

249 |

257 |

264 |

272 |

279 |

288 |

292 |

302 |

|

24 |

225 |

248 |

279 |

288 |

296 |

306 |

314 |

324 |

332 |

343 |

348 |

359 |

|

26 |

264 |

291 |

327 |

337 |

348 |

359 |

369 |

380 |

389 |

402 |

408 |

421 |

|

28 |

306 |

337 |

379 |

391 |

403 |

416 |

427 |

441 |

452 |

466 |

473 |

489 |

|

30 |

351 |

387 |

435 |

449 |

463 |

478 |

491 |

507 |

518 |

535 |

543 |

561 |

|

32 |

399 |

440 |

495 |

511 |

527 |

544 |

558 |

576 |

590 |

609 |

618 |

638 |

Packing of Steel Wire Rope:

Shangahi Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Service

To meet the entirety of our customers business needs, SMC offers its services as a “One-Stop Shop” for business services including Purchasing, Value-Added Manufacturing, Packaging/Labeling, and Delivery. SMC prides itself on achieving superior results and satisfying customer needs. In this, we earnestly strive to fulfill our role as trustworthy and reliable supplier of business services throughout the entire world.

Our Value-Added Manufacturing Services not only save our customer time from having to out-source, but also spare them the cost of dealing with several disparate shops and deadlines.

Application of Steel Wire Rope:

- Construction and Offshore rigging

- Marine Industry and Ministry of Defence divisions

- be used for elevator, crane lifting, hanging basket, colliery steel, seaport, and oilfield.

here

for

price