- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Steel Wire Rope/Steel Cable for Marine Industry

Material: Galvanised, ungalvanised or stainless steel, etc.

Application: Elevator, crane lifting, hanging basket

Steel wire rope is used across a wide spectrum of industries for many applications. A steel wire rope is made up of steel wires that are twisted to form strands. The strands are in turn twisted to form steel wire ropes of different sizes, depending on the desired strength of the steel wire rope. Steel wire ropes are consumables which may be discarded when worn out. Steel wire ropes are used in mooring, towing and lifting systems.

Specification of Steel Wire Rope:

1) Size : From 3mm to 80mm

2) Material of Steel Wire Rope: Galvanized and ungalvanized or stainless steel, etc.

3) Core : IWRC, FC and WSC

4) Tensile Strength : 1960 N/mm2 (EIPS) and 2160 N/mm2 (EEIPS)

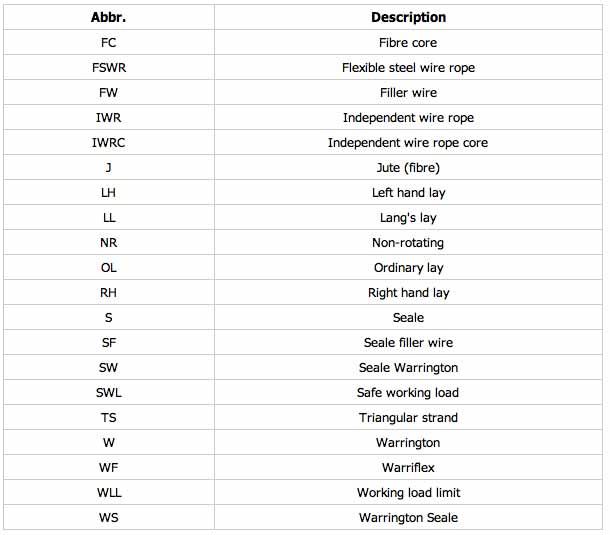

The following abbreviations are commonly used to specify a wire rope:

Wire Rope range:

1) 9×19S+IWR, 9×19W+IWR, 9×21Fi+ IWR, 9×19S+9×7+Fc

2) 9×19W+9×7+Fc, 9×21Fi+9×7+Fc

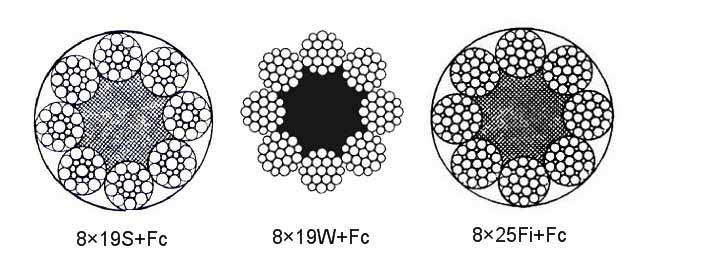

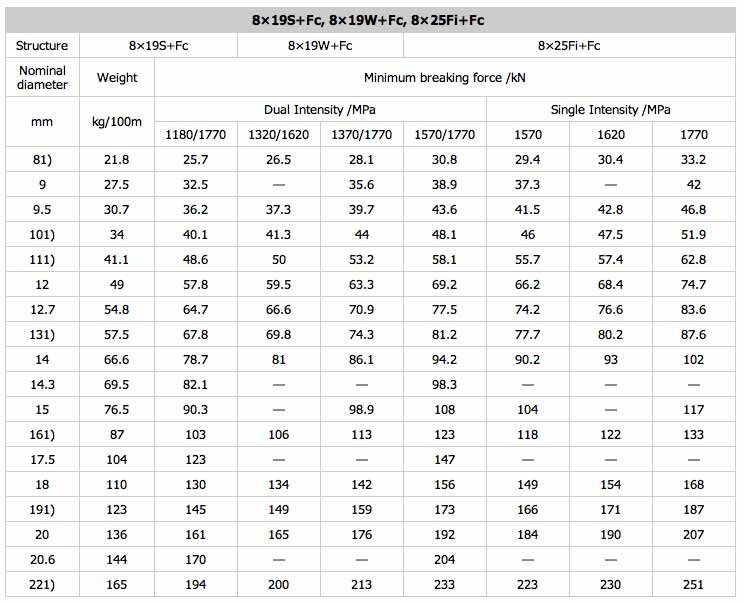

3) 8×19S+Fc, 8×19W+Fc, 8×25Fi+Fc

4) IWRC 6×Fi(29)、IWRC 6×WS(31)、IWRC 6×WS(36)

5) 34×7+Fc, 34×7+IWS, 36×7+Fc, 36×7+IWS

6) 17×7+Fc, 17×7+IWS, 18×7+Fc, 18×7+IWS, 18×19+Fc, 18×19+IWS

7) 18×19S+Fc, 18×19S+IWS, 18×19W+Fc, 18×19W+IWS, etc.

Different Cross-sectional Views of Special Wire Ropes:

Packaging of Steel Wire Rope

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Wire rope is made of plaiting strands of wire – normally medium carbon steel – into a thick cable.

The strands are formed around a core. The strands in wire ropes are made of wore twisted together.

Strands with smaller diameter wires are less abrasion resistant and more fatigue resistant.

Strands made with thicker length of wore are more abrasion resistant and less fatigue resistant.

Applications of Steel Wire Rope:

1) Construction and offshore rigging

2) Marine Industry and Ministry of Defence divisions

3) elevator, crane lifting, hanging basket, colliery steel, seaport, and oilfield

Modern ships, since roughly 1940, have been produced almost exclusively of welded steel.

Early welded steel ships used steels with inadequate fracture toughness,

which resulted in some ships suffering catastrophic brittle fracture structural cracks

(see problems of the Liberty ship).

Since roughly 1950, specialized steels such as ABS Steels

with good properties for ship construction have been used.

Although it is commonly accepted that modern steel has eliminated brittle fracture in ships,

some controversy still exists.

Brittle fracture of modern vessels continues to occur from time to time

because grade A and grade B steel of unknown toughness or

fracture appearance transition temperature (FATT) in ships' side shells

can be less than adequate for all ambient conditions.

here

for

price