- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

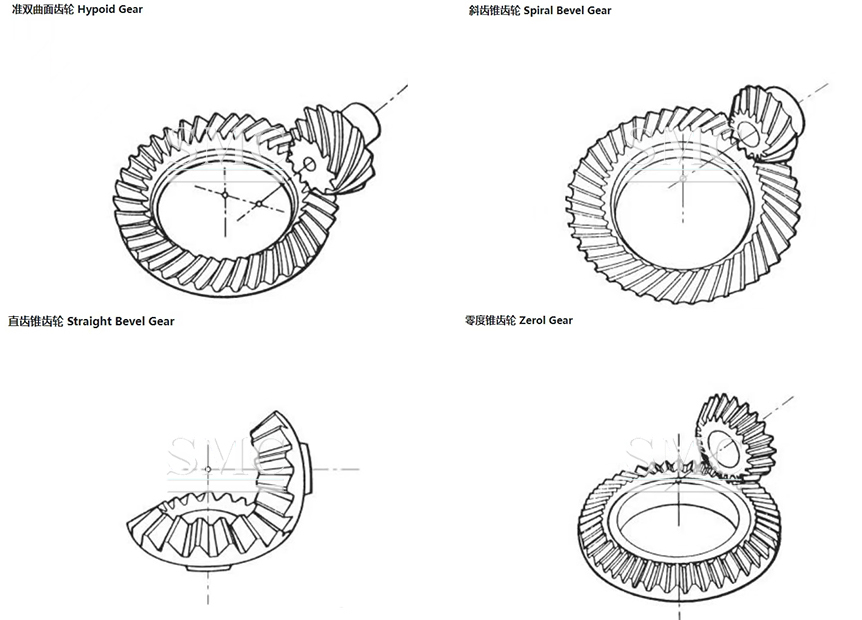

Straight/ Spiral Bevel Gear & Hypoid Gear

Module: M1 - M40

Accuracy Class: DIN 3 - DIN 10, JIS 0 - JIS 4, AGMA 10 - AGMA 15

Transmission Efficiency: 0.94 - 0.98

Diameter: 20mm - 1600mm

Shanghai Metal Corporation is a professional manufacturer and supplier of Straight/ Spiral Bevel Gear & Hypoid Gear with high quality and reasonable price.

Bevel gear refers to a type of bevel gear used for transmission between intersecting axes, mainly for transmitting motion and power between vertical axes. Bevel gears refer to two types: straight bevel gears and spiral bevel gears.

Straight bevel gears are the simplest type of bevel gear to produce and are widely used in various mechanical transmissions. Spiral bevel gears have a helix angle design and a more complex manufacturing process, but their advantage lies in providing higher strength and lower noise.

Hypoid gears look very similar to spiral bevel gears, but their complexity is greater than that of spiral bevel gears. Hypoid gears originated from the development of the automotive industry, as they can increase the diameter of small wheels and achieve double span support. Biasing the small wheels can lower the center of gravity and make the sedan more comfortable; Biasing the small wheel can raise the center of gravity, making the off-road vehicle more capable of overcoming obstacles.

If you want to know more about Straight/ Spiral Bevel Gear & Hypoid Gear price please feel free to contact us, we will reply you within 24 hours

Technical Information of Straight/ Spiral Bevel Gear & Hypoid Gear:

|

Detailed Information of Common Codes |

||||||||||||

|

Code |

Ratio |

Module |

Teeth |

Spiral |

Bore Diameter |

Addendum Circle |

Installation Distance |

Total Length |

Hub Length |

Teeth Width |

Keyway |

Backlash |

|

M2-30 |

1.5 |

M2 |

30 |

R |

20-22 |

61.36 |

40 |

26.8 |

14 |

11 |

6*2.8 |

0.06-0.16 |

|

M2-20 |

1.5 |

M2 |

20 |

L |

15-18 |

43.49 |

45 |

24.96 |

13.33 |

11 |

5*2.3 |

0.06-0.16 |

|

M2.5-30 |

1.5 |

M2.5 |

30 |

R |

22-25 |

76.74 |

50 |

33.6 |

18 |

14 |

6*2.8 |

0.07-0.17 |

|

M2.5-20 |

1.5 |

M2.5 |

20 |

L |

18-20 |

54.43 |

55 |

30.08 |

15.17 |

14 |

6*2.8 |

0.07-0.17 |

|

M3-30 |

1.5 |

M3 |

30 |

R |

25-30 |

92.21 |

60 |

40.34 |

21 |

17 |

8*3.3 |

0.08-0.18 |

|

M3-20 |

1.5 |

M3 |

20 |

L |

22-25 |

65.58 |

65 |

35.17 |

17 |

17 |

6*2.8 |

0.08-0.18 |

|

M4-30 |

1.5 |

M4 |

30 |

R |

35-40 |

122.91 |

70 |

43.99 |

21 |

23 |

10*3.3 |

0.12-0.27 |

|

M4-20 |

1.5 |

M4 |

20 |

L |

30-35 |

87.34 |

85 |

45.53 |

21.67 |

23 |

8*3.3 |

0.12-0.27 |

|

M5-30 |

1.5 |

M5 |

30 |

R |

80+ |

- |

70 |

35.53 |

- |

28 |

- |

0.14-0.34 |

|

M5-20 |

1.5 |

M5 |

20 |

L |

35-40 |

109.2 |

105 |

55.05 |

25.67 |

28 |

10*3.3 |

0.14-0.34 |

|

M6-30 |

1.5 |

M6 |

30 |

R |

90+ |

- |

80 |

38.86 |

- |

34 |

- |

0.16-0.36 |

|

M2-40 |

2 |

M2 |

40 |

L |

20-22 |

81.06 |

45 |

31.83 |

18 |

14 |

6*2.8 |

0.06-0.16 |

|

M2-20 |

2 |

M2 |

20 |

R |

15-18 |

44.2 |

55 |

28.16 |

13.75 |

14 |

5*2.3 |

0.06-0.16 |

|

M2.5-40 |

2 |

M2.5 |

40 |

L |

25-28 |

101.29 |

50 |

33.35 |

16 |

17 |

8*3.3 |

0.07-0.17 |

|

M2.5-20 |

2 |

M2.5 |

20 |

R |

20-22 |

55.12 |

65 |

30.01 |

13.25 |

17 |

6*2.8 |

0.07-0.17 |

|

M3-40 |

2 |

M3 |

40 |

L |

30-35 |

121.57 |

60 |

39.81 |

21 |

20 |

8*3.3 |

0.08-0.18 |

|

M3-20 |

2 |

M3 |

20 |

R |

22-25 |

66.03 |

80 |

38.9 |

18.25 |

20 |

6*2.8 |

0.08-0.18 |

|

M4-40 |

2 |

M4 |

40 |

L |

80+ |

- |

60 |

32.08 |

- |

27 |

- |

0.12-0.27 |

|

M4-20 |

2 |

M4 |

20 |

R |

30-35 |

88.46 |

100 |

45.38 |

17.5 |

27 |

8*3.3 |

0.12-0.27 |

|

M5-40 |

2 |

M5 |

40 |

L |

90+ |

- |

70 |

35.2 |

- |

34 |

- |

0.14-0.34 |

|

M5-20 |

2 |

M5 |

20 |

R |

40-45 |

109.91 |

125 |

57.11 |

21.75 |

34 |

12*3.3 |

0.14-0.34 |

|

M6-40 |

2 |

M6 |

40 |

L |

110+ |

- |

80 |

37.89 |

- |

40 |

- |

0.16-0.36 |

Packaging of Straight/ Spiral Bevel Gear & Hypoid Gear:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price