- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Cup Lock Scaffolding

Material: Steel Q235,Q345

Size: Standard Size or Customizing Size

Produce Technology: Fully Automatic welding

Surface: Hot Dip Galvanized/Electroplate/Power Coating/Dip Painting

-

1. Cup lock Scaffolding Systems are built to be the most reliable and efficient scaffold available.

2. Safe and convenient, hot-dip galvanized components.

3. Fast-erection systemized access scaffold, Full range of accessories.

-

1. A foothold in the high altitude for construction personnel in the construction

2. Skeleton of peripheral protection.

3. Support the important vertical support of the template.

4. Unloading platform.

-

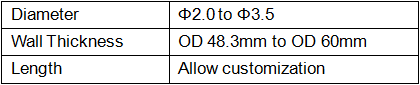

Pipe Diameter: 48.3mmx3.25mm, 48.3mmx2.5mm, 48.3mmx2.0mm 60mmx3.2

Pipe Thickness: 3.25/3.2mm for Standard, 3.25/3.2mm for Ledger, 2.50mm/2.00mm for Brace

Basic Components: Standard, Ledger, Brace, Ladder, Base jack,etc

Standard for steel tubular steel scaffolding: SY/T5768-95, GB/T3091-2001, ASTMA53, BS1387

Safety technical regulations: JGJ 231-2010

-

1. Completely modular structure, reduces the impact of human factors of making the construction quality of the scaffold.

2. Adopts hot dip zinc plating process, effectively prevents the component in the use of internal corrosion caused by the material to decline, to ensure consistency of product performance.

3. Construction is convenient, high efficiency, saving time limit for a project.

4. Substantial savings in steel consumption.

5. Substantial savings in construction time.

Packing Information:

1. Normally scaffolding is loaded to containers in bulk in order to load as more as possible and save sea freight.

2. If customer want to unload by forklift in order to save the labor cost, then we will pack the scaffolding in steel pallet or steel case.

3. Other special requirements can be discussed by both. We can service for you sincerely.

here

for

price