- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Generator

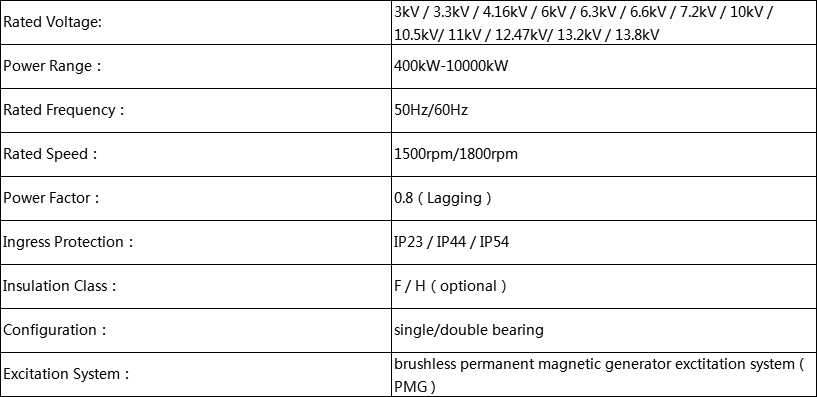

| Rated Voltage: |

3kV / 3.3kV / 4.16kV / 6kV / 6.3kV / 6.6kV / 7.2kV / 10kV / 10.5kV/ 11kV / 12.47kV/ |

|

Power Range: |

400kW-10000kW |

| Rated Speed: | 1500rpm/1800rpm |

|

|

|

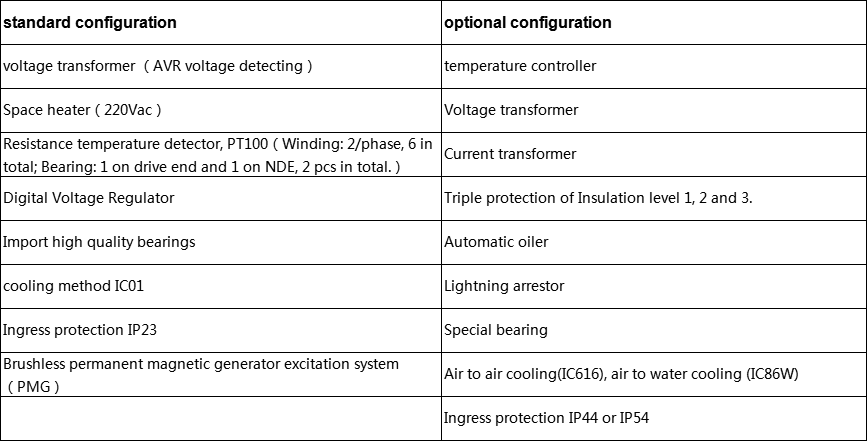

Technical Characteristics

Class F stator is wrapped with class F epoxy mica tape and mould pressed. Class H stator coil is operated with the mature class H insulation technology and impregnated in VPI (vacuum pressure impregnating) system. Both class F and class H stator coil are processed with anti-corona treatment. Meantime, the stator coil is designed with skewed slot structure to effectively reduce harmonic wave. Enhance the mechanical strength on the end of stator winding to effectively prevent and withstand the deformation on the end of stator caused by the sudden load or short circuit.

Triple insulated structure of the rotor coil can effectively improve the rotor turn to turn and interlayer insulation, the damp-proof and anti-corrosion ability. It will enhance the mechanical strength on the end of the winding to prevent the rotor winding from deforming under high rotation speed. Accordingly, the lifespan, reliability and environment adaptability of generator is also substantially improved. The rotating rectifier is designed as bi-section structure which is convenient for maintenance and do not require any knock down on the generator.

5/6 or 2/3 pitch option can decrease the content of voltage harmonic wave and is suitable for nonlinear load application. The standard configuration is temperature sensor, PT100 and space heater.

The power range of ENGGA high voltage generator is from 400kW to 10000kw.

Standard voltage is from 3kV to 13.8kV. Special voltage is available according to customers’ requirement.

50Hz or 60Hz are available.

The standard rotor configuration of high voltage generator is 4 pole salient rotor, with the speed at 1500r/min or 1800r/min. And 6/8/10/12/14 poles low/medium speed high voltage synchronous generator option is available.

THD <2%, TIF <50, THF <2%。

Overload allowance: 10% (1 hour in every 12 hours)

The three phrases short circuit current is more than three times the rated current. (>300% In,10s)

Cooling Structure

Radial and axial ventilation design in interior side ensures the sufficient cooling.

Center Height

The center height is from EG450 to EG1000 and can be customized.

Installation Methord

The standard installation method is IMB20, double bearing configuration (single bearing is optional), and can be customized according to customer’s requirement.

Ingress Protection

The standard ingress protection is IP23. IP44 and IP54 are optional.

Cooling Method

The standard configuration is IC01. The IP54 air-air cooling and air-water cooling is available.

Dynamic Balancing

All rotors have been dynamically balanced at factory before delivery and the accuracy of dynamic balancing conforms to ISO1940.

Over Speed Capacity

The generator maximum over speed is 2160rpm for 2 mins.

Rotation Direction

The standard generator rotation direction is clockwise viewed from the drive end of generator, while counter-clockwise rotation direction is optional according to customer’s requirement.

Terminal Box

The interior modular design of the generator terminal box has reserved the space for future voltage transformer and current transformer mounting. The terminal box of digital voltage regulator and auxiliary terminal box are mounted on the external side of the terminal box, which is convenient for wiring, debugging and the personal safety is assured.

Optional Accessories:

here

for

price