- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

PVDF Painted Steel Coil

Thickness: 0.3mm ~ 2.0mm

Standard: ASTM/ JIS/ GBT/ EN etc

Width: 600mm ~ 1500mm

Shanghai Metal Corporation is a professional manufacturer and supplier of PVDF painted Steel Coil with high quality and reasonable price.

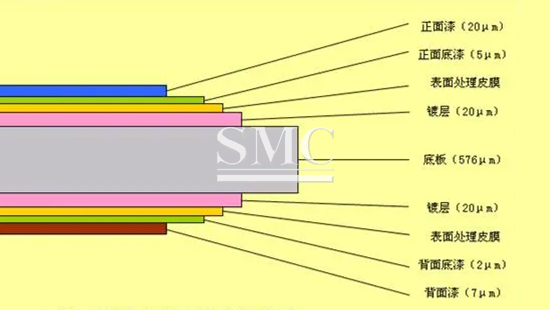

PVDF painted steel coil adopts high-performance polyvinylidene fluoride resin coating or (called fluorocarbon resin), and uses KYNAR500 with a content of at least 70% Or HYLAR5000 as top coat with two sides, double baking and double coating; The substrate can be hot-dip galvanized, coated with 5% aluminum zinc, and coated with 55% aluminum zinc respectively. The three types of PVDF painted steel products not only has excellent property of weather resistance, corrosion resistance, chemical and solvent resistance, heat resistance but also has good UV resistance, pollution resistance and durable & long-lasting aesthetic colors.

If you want to know more about PVDF painted Steel Coil price please feel free to contact us, we will reply you within 24 hours

Technical Information of PVDF Painted Steel Coil:

|

Top paint |

Paint thickness/ μm |

Pencil hardness |

180° bend |

Impact(J) |

Salt pray resistance |

|

PE |

≥20 |

≥F |

≤4T |

≥9 |

≥1000hours |

|

SMP |

≥20 |

≥F |

≤4T |

≥9 |

≥1000hours |

|

HDP |

≥20 |

≥HB |

≤4T |

≥9 |

≥1500hours |

|

PVDF |

≥20 |

≥HB |

≤4T |

≥9 |

≥2000hours |

|

Base metal of Prepainted steel |

Application |

||||

|

Hot-dip Zinc |

Hot-dip Zinc-Fe alloy |

Hot-dip Al-Zinc alloy |

Hot-dip Z-Al alloy |

Eletro-galvanized |

|

|

TDC51D+Z |

TDC51D+ZF |

TDC51D+AZ |

TDC51D+ZA |

TDC01+ZE |

CQ |

|

TDC52D+Z |

TDC52D+ZF |

TDC52D+AZ |

TDC52D+ZA |

TDC03+ZE |

DQ |

|

TDC53D+Z |

TDC53D+ZF |

TDC53D+AZ |

TDC53D+ZA |

TDC04+ZE |

DDQ |

|

TDC54D+Z |

TDC54D+ZF |

TDC54D+AZ |

TDC54D+ZA |

/ |

EDDQ |

|

TS250GD+Z |

TS250GD+ZF |

TS250GD+AZ |

TS250GD+ZA |

/ |

Structure |

|

TS280GD+Z |

TS280GD+ZF |

TS280GD+AZ |

TS280GD+ZA |

/ |

Structure |

|

/ |

/ |

TS300GD+AZ |

/ |

/ |

Structure |

|

TS320GD+Z |

TS320GD+ZF |

TS320GD+AZ |

TS320GD+ZA |

/ |

Structure |

|

TS350GD+Z |

TS350GD+ZF |

TS350GD+AZ |

TS350GD+ZA |

/ |

Structure |

|

TS550GD+Z |

TS550GD+ZF |

TS550GD+AZ |

TS550GD+ZA |

/ |

Structure |

|

Base metal of Prepainted steel |

Application |

||||

|

Hot-dip Zinc |

Hot-dip Zinc-Fe alloy |

Hot-dip Al-Zinc alloy |

Hot-dip Z-Al alloy |

Eletro-galvanized |

|

|

TDC51D+Z |

TDC51D+ZF |

TDC51D+AZ |

TDC51D+ZA |

TDC01+ZE |

CQ |

|

TDC52D+Z |

TDC52D+ZF |

TDC52D+AZ |

TDC52D+ZA |

TDC03+ZE |

DQ |

|

TDC53D+Z |

TDC53D+ZF |

TDC53D+AZ |

TDC53D+ZA |

TDC04+ZE |

DDQ |

|

TDC54D+Z |

TDC54D+ZF |

TDC54D+AZ |

TDC54D+ZA |

/ |

EDDQ |

|

TS250GD+Z |

TS250GD+ZF |

TS250GD+AZ |

TS250GD+ZA |

/ |

Structure |

|

TS280GD+Z |

TS280GD+ZF |

TS280GD+AZ |

TS280GD+ZA |

/ |

Structure |

|

/ |

/ |

TS300GD+AZ |

/ |

/ |

Structure |

|

TS320GD+Z |

TS320GD+ZF |

TS320GD+AZ |

TS320GD+ZA |

/ |

Structure |

|

TS350GD+Z |

TS350GD+ZF |

TS350GD+AZ |

TS350GD+ZA |

/ |

Structure |

|

TS550GD+Z |

TS550GD+ZF |

TS550GD+AZ |

TS550GD+ZA |

/ |

Structure |

Packaging of PVDF Painted Steel Coil:

Products of Shanghai Metal Corporation are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Notes:

1. To avoid damaging the surface of the product, careful handling is necessary during handling, transportation, forming, and installation. Improper use of forming lubricants will affect product characteristics and cause surface contamination. It is recommended not to use them unless necessary.

2. Under no circumstances should steel coils be stored in a damp environment, as the rainwater or moisture drawn into the surface of the steel plate by capillary action will not evaporate properly, which can easily lead to deterioration of product characteristics, shorten the expected service life, and affect the appearance of the product. Special attention must also be paid to the storage of formed cutting boards.

3.The service life of PVDF painted steel products depends on the environment, atmospheric conditions, and conditions of the area where the building is located.

here

for

price