- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

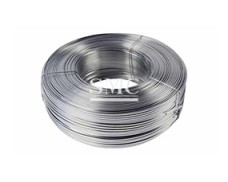

Safety Valve

Material: Cast steel, Forged steel, Stainless steel

Size: DN25~DN600

Structural form of safety valve: Valve bonnet of sealed safety valve, Valve bonnet of open safety valve, Safety valve with a lever, Full-lift safety valve

Suitable medium: Water, Steam, Oil products, Etc

Shanghai Metal Corporation is experienced manufacturer of safety valve in China since 1980s.

SMC safety valve, the best extra-pressure protection device takes care of press equipment, container and on-line pipe.When medium's pressure rises over the allowed pressure, safety valve will automatically open and fully discharge to protect the equipment from pressure going on rising and will automatically close when the pressure lowers to the setting pressure.The valve bonnet of sealed safety valve prevents dust and foreign matters from invading. Meanwhile protect toxic combustible media from overflowing. The valve bonnet of open safety valve can favor the spring seat in lowering temperature inside of, It is mainly used for the pipeline and container with steam medium. The safety valve with a radiator is suitable for the medium with a temperature over 350 ℃.The safety valve with a lever, it makes use of open manually,when the media pressure over 75% of setting pressure.Full-lift safety valve opening height is more than one fourth times of the flow diameter. It has an advantage of discharging greatly. Low-lift safety valve opening height is between one twentieth to one fortieth times of the flow diameter.

If you want to know more about safety valve price, please feel free to contact us, we will reply you within 24 hours.

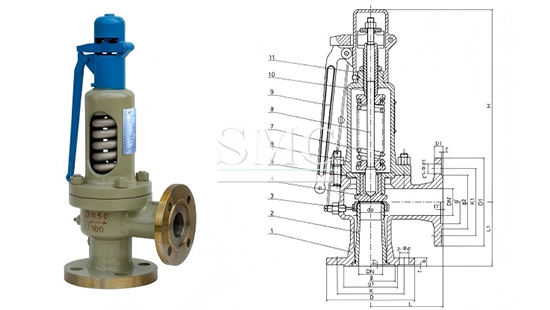

Technical Information of Safety Valve:

|

Type |

(DN) |

do |

D |

K |

g1 |

b |

f |

Z-φd |

DN" |

D1 |

k1 |

g2 |

|

A47H-16C |

20 |

15 |

105 |

75 |

55 |

16 |

2 |

4-14 |

20 |

105 |

75 |

55 |

|

25 |

20 |

115 |

85 |

65 |

16 |

2 |

4-14 |

25 |

115 |

85 |

65 |

|

|

32 |

25 |

140 |

100 |

78 |

18 |

2 |

4-18 |

32 |

140 |

100 |

78 |

|

|

40 |

32 |

150 |

110 |

85 |

18 |

3 |

4-18 |

40 |

150 |

110 |

85 |

|

|

50 |

40 |

165 |

125 |

100 |

20 |

3 |

4-18 |

50 |

165 |

125 |

100 |

|

|

65 |

50 |

185 |

145 |

120 |

20 |

3 |

4-18 |

65 |

185 |

145 |

120 |

|

|

80 |

65 |

200 |

160 |

135 |

20 |

3 |

8-18 |

80 |

200 |

160 |

135 |

|

|

100 |

80 |

220 |

180 |

155 |

22 |

3 |

8-18 |

100 |

220 |

180 |

155 |

|

|

125 |

100 |

250 |

210 |

185 |

22 |

3 |

8-18 |

125 |

250 |

210 |

185 |

|

|

150 |

125 |

285 |

240 |

210 |

24 |

3 |

8-23 |

150 |

285 |

240 |

210 |

|

|

200 |

150 |

340 |

295 |

265 |

26 |

3 |

12-23 |

200 |

340 |

295 |

265 |

|

|

250 |

200 |

405 |

355 |

320 |

30 |

3 |

12-26 |

250 |

405 |

355 |

320 |

|

|

300 |

250 |

460 |

410 |

375 |

30 |

4 |

12-26 |

300 |

460 |

410 |

375 |

|

|

A47H-25 |

20 |

15 |

105 |

75 |

55 |

16 |

2 |

4-14 |

20 |

105 |

75 |

55 |

|

25 |

20 |

115 |

85 |

65 |

16 |

2 |

4-14 |

25 |

115 |

85 |

65 |

|

|

32 |

25 |

140 |

100 |

78 |

18 |

2 |

4-18 |

32 |

140 |

100 |

78 |

|

|

40 |

32 |

150 |

110 |

85 |

18 |

3 |

4-18 |

40 |

150 |

110 |

85 |

|

|

50 |

40 |

165 |

125 |

100 |

20 |

3 |

4-18 |

50 |

165 |

125 |

100 |

|

|

65 |

50 |

185 |

145 |

120 |

22 |

3 |

8-18 |

65 |

185 |

145 |

120 |

|

|

80 |

65 |

200 |

160 |

135 |

24 |

3 |

8-18 |

80 |

200 |

160 |

135 |

|

|

100 |

80 |

230 |

190 |

160 |

24 |

3 |

8-23 |

100 |

220 |

180 |

155 |

|

|

125 |

100 |

270 |

220 |

188 |

28 |

3 |

8-26 |

125 |

250 |

210 |

185 |

|

|

150 |

125 |

300 |

250 |

218 |

30 |

3 |

8-26 |

150 |

285 |

240 |

210 |

|

|

200 |

150 |

360 |

310 |

278 |

34 |

3 |

12-26 |

200 |

340 |

295 |

265 |

|

|

250 |

200 |

425 |

370 |

332 |

36 |

3 |

12-30 |

250 |

405 |

355 |

320 |

|

|

300 |

250 |

485 |

430 |

390 |

40 |

4 |

16-30 |

300 |

460 |

410 |

375 |

Packaging of Safety Valve:

Shanghai Metal Corporation Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

NOTICE:

1. Safety valves should be installed vertically and positioned at the gas phase interface of containers or pipelines.

2. The outlet of the safety valve should be unobstructed to avoid back pressure. If a discharge pipe is installed, its inner diameter should be larger than the outlet diameter of the safety valve. The discharge port of the safety valve should be protected against freezing. For containers containing flammable, toxic, or highly toxic media, the discharge pipe should be directly connected to a safe outdoor location or have proper treatment facilities. No valves are allowed to be installed in the discharge pipe.

3. No valves shall be installed between pressure equipment and safety valves. For containers containing flammable, explosive, toxic or viscous media, globe valves may be installed for easy replacement and cleaning. The structure and diameter size of the globe valve should not hinder the normal operation of the safety valve. During normal operation, the shut-off valve must be fully opened and sealed with lead.

4. For pressure vessels with flammable, explosive or toxic media, the medium discharged from the safety valve must have safety devices and recovery systems. The installation of lever type safety valves must maintain a vertical position, and spring safety valves should also be installed vertically to avoid affecting their operation.

here

for

price