- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

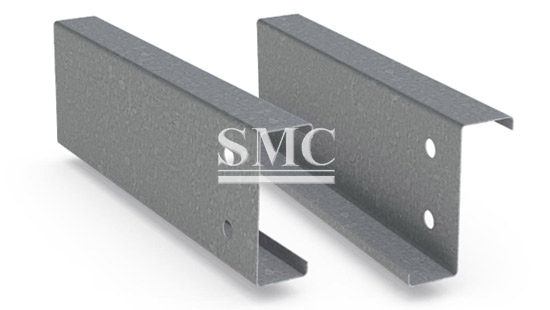

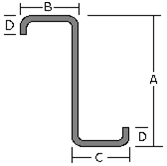

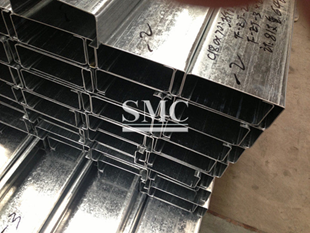

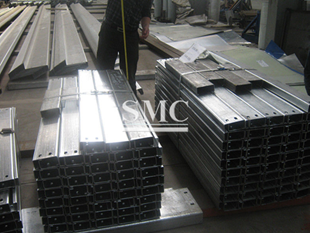

C Steel Purlins

Surface Finished: Black or Galvanized

Perforated: According to customer's requirement

Grade: DC01, DC03, SGCC, DX51D, DX53D, etc

Shanghai Metal Purlins and Girts are roll-formed from High Tensile Galvanized steel. They are primarily used to provide lightweight, economical, efficient roofing and cladding support systems for framed structures. Purlins and Girts are available in a range of different sizes and configurations.

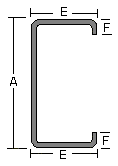

Specifications of C Steel Purlins:

|

|

|||||||||

|

Section |

Thickness |

A |

Z Purlin |

C Purlin |

Kg's/Mtr |

||||

|

C / Z |

mm |

B |

C |

D |

E |

F |

AS1397 |

||

|

10012 |

1.2 |

102 |

53 |

49 |

12.5 |

51 |

12.5 |

2.07 |

|

|

10015 |

1.5 |

102 |

53 |

49 |

13.5 |

51 |

13.5 |

2.58 |

|

|

10019 |

1.9 |

102 |

53 |

49 |

14.5 |

51 |

14.5 |

3.25 |

|

|

15012 |

1.2 |

152 |

65 |

61 |

15.5 |

64 |

14.5 |

2.84 |

|

|

15015 |

1.5 |

152 |

65 |

61 |

16.5 |

64 |

15.5 |

3.54 |

|

|

15019 |

1.9 |

152 |

65 |

61 |

17.5 |

64 |

16.5 |

4.46 |

|

|

15024 |

2.4 |

152 |

66 |

60 |

19.5 |

64 |

18.5 |

5.62 |

|

|

20015 |

1.5 |

203 |

79 |

74 |

15 |

76 |

15.5 |

4.44 |

|

|

20019 |

1.9 |

203 |

79 |

74 |

18.5 |

76 |

19 |

5.68 |

|

|

20024 |

2.4 |

203 |

79 |

73 |

21.5 |

76 |

21 |

7.15 |

|

|

25019 |

1.9 |

254 |

79 |

74 |

18 |

76 |

18.5 |

6.43 |

|

|

25024 |

2.4 |

254 |

79 |

73 |

21 |

76 |

20.5 |

8.1 |

|

|

30024 |

2.4 |

300 |

100 |

93 |

27 |

96 |

27.5 |

10.01 |

|

|

30030 |

3 |

300 |

100 |

93 |

31 |

96 |

31.5 |

12.6 |

|

|

35030 |

3 |

350 |

129 |

121 |

30 |

125 |

30 |

15.09 |

|

Process: Purlin is cold-formed form hot rolled strip or galvanzied strip.

Advantages of C Purlins

•Ability to span length

•Purlin construction is easier to assemble and handle

•Assured dimensions and straightness

•High durability, versatility and uniform quality

•Low transportation cost due to decreased weight

Application of Purlin:

In steel construction, the term purlin typically refers to roof framing members that span parallel to the building eave and support the roof decking or sheeting. The steel purlins are in turn supported by rafters or walls. C Purlins are light in weight and perfect for simple span construction.

•Construction industry: steel structure (purlin, wall beam); Self-assembled of building elements (lightweight roof, bracket);

• Mechanical light industry: column, beam and arm, etc;

• Solar power generation (photovoltaic bracket);

• Automobile manufacturing, transmission tower, ship bridges, road and railway construction, equipment room container, mineral bracket, etc.

here

for

price