- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

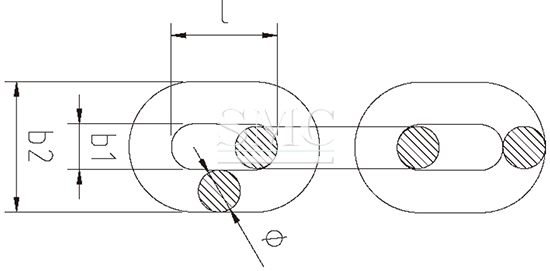

G100 Lifting Chain

Strength Grade: G100

Chain Diameter: φ6mm, φ8mm, φ10mm, φ13mm, φ16mm, φ19mm, φ22mm, φ26mm, φ32mm, φ40mm, φ45mm

Material: alloy steel SAE8620

Shanghai Metal Corporation is a professional manufacturer and supplier of G100 Lifting Chain with high quality and reasonable price.

G100 lifting chain is a high-strength and durable lifting chain. The ultimate load of G100 lifting chain is 30% higher than the current G80 chain. The raw materials used in the production are CrNiMo special alloy steel, which has undergone high-strength treatment and has super strong bearing capacity and wear resistance. It is widely used in important industries such as ports, electricity, steel, shipbuilding, mining, railways, construction, metallurgy and chemical industry, automobile manufacturing, pipeline auxiliary equipment, maritime rescue, marine engineering, airport construction, bridges and mechanical equipment for infrastructure construction projects.

If you want to know more about G100 Lifting Chain price please feel free to contact us, we will reply you within 24 hours

Technical Information of G100 Lifting Chain:

|

G100 Lifting Chain |

||||||

|

Size/mm |

Inner width |

Outside width |

Weight (kg/m) |

Min WLL |

Test Load(KN) |

MBL |

|

6x18 |

7.8 |

22.2 |

0.8 |

1.4 |

35.3 |

56.5 |

|

7x21 |

9.2 |

26.3 |

1.1 |

2 |

49.5 |

79.1 |

|

8x24 |

10.4 |

29.6 |

1.4 |

2.5 |

62.8 |

101 |

|

9x27 |

11.7 |

33.3 |

1.8 |

3.2 |

79.5 |

127 |

|

10x30 |

13 |

37 |

2.2 |

4 |

98.1 |

157 |

|

11x33 |

14.3 |

40.7 |

2.7 |

4.8 |

119 |

190 |

|

12x36 |

15.6 |

44.4 |

3.1 |

5.8 |

141 |

226 |

|

13x39 |

16.9 |

48.1 |

3.8 |

6.8 |

166 |

265 |

|

14x42 |

18.2 |

51.8 |

4.4 |

7.9 |

193 |

308 |

|

16x48 |

20.8 |

59.2 |

5.7 |

10 |

251 |

402 |

|

18x54 |

23.4 |

66.6 |

7.3 |

13 |

318 |

509 |

|

20x60 |

26 |

74 |

9 |

16 |

393 |

628 |

|

22x66 |

28.6 |

81.4 |

10.9 |

19 |

475 |

760 |

Packaging of G100 Lifting Chain:

Products of Shanghai Metal Corporation are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)SMC Standard

2)Customization

Notes:

Attention :

1. The lifted object cannot exceed the rated load;

2. Do not only come into contact with sharp objects;

3. Check before each use.

Maintenance:

1. The sprocket should not be skewed or swing when installed on the shaft. The end faces of two sprockets in the same transmission component should be located in the same plane. When the center distance of the sprockets is less than 0.5 meters, a deviation of 1 millimeter is allowed; When the center distance of the sprocket is above 0.5 meters, a deviation of 2 millimeters is allowed. But it is not allowed to have friction on the side of the sprocket teeth. If the two wheels are offset too much, it is easy to cause chain detachment and accelerated wear. When replacing the sprocket, it is necessary to pay attention to checking and adjusting the offset;

2. The tightness of the lifting chain should be appropriate. If it is too tight, it will increase power consumption and the bearings are prone to wear; Too loose chains are prone to jumping and detachment. The degree of tightness of the chain is: when lifted or pressed from the middle of the chain, the center distance between the two sprockets is about 2% -3%;

3. If the new lifting chain is too long or stretched after use, it is difficult to adjust. The chain links can be removed depending on the situation, but they must be even. The chain link should pass through the back of the chain, the locking plate should be inserted outside, and the opening of the locking plate should face in the opposite direction of rotation.

here

for

price