- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

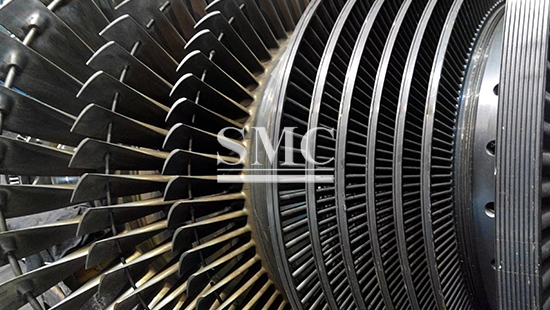

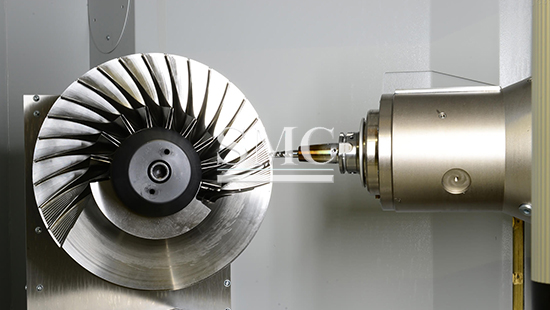

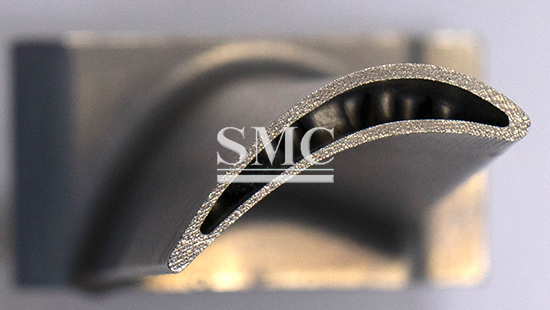

Steam Turbine Blades

Blade classification: fixed blade, moving blade and guide blade.

Material grades: 22Cr12NiMoWV, ZCrlZnimo 1wiv, 1Cr13, 2Cr13, 1Cr11MoV, 1Cr12W1MoV, TiAl6V4 and TiAl7Mo4, etc.

Shanghai Metal Corporation is a professional manufacturer and supplier of Steam Turbine Blades with high quality and reasonable price.

Our Steam Turbine Blades, meticulously fabricated from premium-grade high-strength materials, possess extraordinary durability and unwavering reliability in the most demanding operating environments. The blades are precision-engineered with advanced manufacturing techniques, ensuring optimal aerodynamic performance to maximize energy conversion efficiency. Their robust construction enables them to endure extreme conditions.Each blade is designed and tested rigorously to meet the strictest industry standards, supporting the seamless integration of the rotor, stator, and other key components within the complex machinery of a steam turbine. Not only do they play a pivotal role in converting thermal energy into mechanical energy and then into electrical energy with high precision, but they also contribute significantly to the overall longevity and performance of the power generation system, underpinning the essential energy supply that drives our daily lives and industrial progress.

If you want to know more about Steam Turbine Blades price please feel free to contact us, we will reply you within 24 hours

Technical Information of Steam Turbine Blades:

|

Backpressure |

kPa |

Blocking backpressure |

10kPa |

14kPa |

20kPa |

25kPa |

30kPa |

32kPa |

34kPa |

Maximum full back pressure |

|

|

High pressure cylinder exhaust temperature |

C |

330.3 |

330.4 |

331.4 |

333.1 |

335.1 |

336.9 |

337.6 |

—338.3 |

340.2 |

|

|

Main steam flow |

kg/h |

1025951 |

1027445 |

1035859 |

060268 |

1083429 |

1104900 |

1112992 |

1120826 |

1142839 |

|

|

Reheat steam flow |

kg/h |

865382 |

866602 |

873286 |

892680 |

911019 |

927991 |

934373 |

940552 |

957901 |

|

|

Low pressure cylinder exhaust steam dryness |

% |

93.36 |

93.2 |

93.25 |

94.12 |

95.02 |

96.15 |

96.12 |

96.39 |

97.16 |

|

|

Low pressure cylinder exhaust enthalpy |

kJ/kg |

2417.6 |

2422 |

2436.3 |

2471.3 |

2501.6 |

2527.9 |

2537.4 |

2546.4 |

2570.9 |

|

|

Low pressure cylinder exhaust flow |

kg/h |

668246 |

673961 |

686461 |

709181 |

728363 |

745832 |

752376 |

758697 |

776423 |

|

|

Makeup water rate |

% |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

0 |

|

|

Final feed water temperature |

C |

271.8 |

271.9 |

272.4 |

273.8 |

275.2 |

276.5 |

276.9 |

2774 |

278.6 |

|

|

Steam turbine characteristic data at TMCR flow rate |

|||||||||||

|

Backpressure |

kPa |

Blocking backpressure |

10kPa |

14kPa |

20kPa |

25kPa |

30kPa |

32kPa |

34kPa |

Maximum full back pressure |

|

|

Unit output |

MW |

356.596 |

356.246 |

354.479 |

348.531 |

342.164 |

336.380 |

334.231 |

332.182 |

326.539 |

|

|

Heat consumption of steam turbine generator setvalue |

kJ/kWh |

8141.9 |

8149.9 |

8189.45 |

8330.1 |

8485.1 |

8630.9 |

8686.4 |

8740.0 |

8890.9 |

|

|

Main steam pressure |

MPa(a |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

16.7 |

|

|

Reheat steam pressure |

MPa(a) |

3.799 |

3.799 |

3.799 |

3.799 |

3.8 |

3.8 |

3.8 |

3.8 |

3.8 |

|

|

High pressure cylinder exhaust pressure |

MPa(a |

4.221 |

4.221 |

4.222 |

4.221 |

4.222: |

4.222 |

4.222 |

4.222 |

4.222 |

|

|

Main steam temperature |

C |

538 |

538 |

538 |

538 |

538 |

538 |

538 |

538 |

538 |

|

|

Reheat steam temperature |

C |

538 |

538 |

538 |

538 |

538: |

538 |

538 |

538 |

538 |

|

|

High pressure cylinder exhaust temperature |

C |

338.9 |

338.9 |

338.9 |

338.9 |

338.9 |

338.9 |

338.9 |

339.0 |

339.0 |

|

|

Main steam flow |

kg/h |

1128783 |

1128783 |

1128783 |

1128783 |

1128783 |

1128783 |

1128783 |

1128783 |

1128783 |

|

|

Reheat steam flow |

kg/h |

946761 |

946761 |

947063 |

946788 |

946800 |

946810 |

946803 |

946807 |

946831 |

|

|

Low pressure cylinder exhaust steam dryness |

% |

93.24 |

93.04 |

93.0 |

93.75 |

94.75 |

95.67 |

96.01 |

96.34 |

97.25 |

|

|

Low pressure cylinder exhaust enthalpy |

kj/kg |

2414.7 |

2418.3 |

2430.3 |

2462.4 |

2495.1 |

2524.3 |

2535.0 |

2545.2 |

2573.1 |

|

|

Low pressure cylinder exhaust flow |

kg/h |

723945 |

729246 |

737639 |

747358 |

753789 |

759287 |

761286 |

763193 |

768440 |

|

|

Makeup water rate |

% |

0 |

0 |

0 |

0 |

01 |

0 |

0 |

0 |

0 |

|

|

Auxiliary machine cooling water temperature |

C |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

Final feed water temperature |

C |

277.8 |

277.8 |

277.9 |

277.8 |

277.8 |

277.8 |

277.8 |

277.8 |

277.8 |

|

Packaging of Steam Turbine Blades:

Shanghai Metal Corporation spares no effort to guarantee that all steam turbine blades are packaged and labeled following the most stringent industry standards and customer requirements. The protection of these precision-engineered components during transportation and storage is of paramount importance. We utilize highly durable packaging materials and provide conspicuous labeling for easy recognition. Moreover, bespoke packaging arrangements can be provided at the request of customers to accommodate the unique demands of diverse projects. By doing so, the integrity and quality of the steam turbine blades are preserved from the production line to the installation site, ensuring the seamless and efficient installation of steam turbines.

1) Individual Packaging: Each blade is individually wrapped with shock-absorbing and scratch-resistant materials, such as high-density foam or soft plastic films. This safeguards the blade's delicate edges and surfaces from potential damage during handling and transit.

2) Carton Boxes: Blades are then placed in custom-designed carton boxes. These boxes are made of thick, corrugated cardboard that offers additional protection against impacts and provides a stable environment. The carton boxes also have built-in compartments or dividers to keep the blades separated and prevent them from rubbing against each other.

3) Wooden Crates or Pallets: For long-distance transportation or when extra security is needed, the carton boxes containing the blades are further secured on wooden crates or pallets. The wooden structures are built to withstand heavy loads and rough handling, ensuring the blades arrive at their destination intact.

4) Anti-Rust Measures: Given that steam turbine blades are often exposed to humid environments or may come into contact with moisture during transit, anti-rust treatments are applied. This could include coating the blades with a thin layer of rust inhibitor or placing desiccant packs inside the packaging to absorb any moisture.

5) Marking and Labeling: Clear and comprehensive markings are made on the packaging. This includes the blade model, part number, manufacturing date, batch number, and any special handling instructions. Such information enables quick identification and proper handling of the blades at all stages of the supply chain.

here

for

price