- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

Molybdenum Discs/ Circular Plates

Grade: Mo1, Mo3G(MoLa10), TZM(Molibdenum Alloy 364), JMo1, Mo 360, Mo361

Standard: GB/T 3876-2007, GB/T 3877-83, ASTM B386-91

Shanghai Metal Corporation is a leading Molybdenum Discs/Circular Plate manufacturer and supplier.

Molybdenum is a necessary trace element for the human body, animals and plants. It is silvery white metal, hard and tough. Various tissues of the human body contain molybdenum, and the total amount in the human body is 9 mg, and the content in the liver and kidney is the highest.

According to the statistics of molybdenum consumption in various countries around the world, the application of molybdenum in the steel industry still occupies the most important position. As an alloying element of steel, molybdenum can improve the strength of steel, especially high temperature strength and toughness; improve the corrosion resistance of steel in acid-base solution and liquid metal; improve the wear resistance of steel and improve hardenability and weldability And heat resistance.

If you want to know more about our copper products or Molybdenum Discs/Circular Plate price please feel free to contact us, we will reply you within 24 hours.

-

1) Grade: Mo1,Mo3G(MoLa10),TZM(Molibdenum Alloy 364),JMo1, Mo 360, Mo361

2) Standard: GB/T 3876-2007,GB/T 3877-83,ASTM B386-91

3) Thickness: 0.1mm-30mm

4) Diameter: 2mm-600mm

-

-

-

1) Molybdenum Discs adopts the material Molybdenum with a high purity of 99.9%;

2) Surface of Molybdenum Discs and plate has metallic silver luster;

3) Its radiation shielding effect is equivalent to that of lead plate;

4) Our Molybdenum Discs and plate can be as thin as 0.1mm ;

5) Molybdenum Discs from Achemetal is under vacuum annealing and leveling before delivery;

-

-

Molybdenum Discs is widely used in aerospace, electronics, lighting, medical equipment, vacuum coating, electric vacuum stove electrode, heat insulation screen, etc as the radiation shielding material and radiation-protective equipment.

-

1) Hardness

2) Tensile Strength

3) Elongation

4) Metal-Detector

5) Conductivity

6) Chemical Content

-

Technical information of Molybdenum discs/circular plates:

Production process:

Molybdenum embryo (raw material) - inspection - hot rolling - leveling and annealing - caustic washing - inspection - warm rolling - vacuum annealing - cold rolling - leveling - shearing - vacuum annealing - inspection - packaging

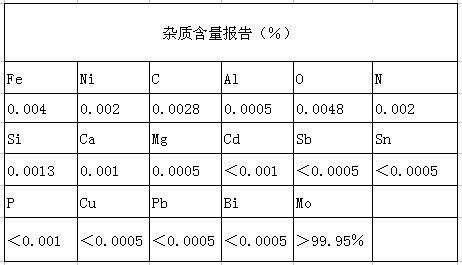

Chemiacal Components of Molybdenum discs/circular plates:

Chemical properties of Molybdenum discs/circular plates:

Purity: pure molybdenum plate Mo ≥99.95% high temperature molybdenum plate: Mo≥99

Density: 10.1g/cm3

Flatness: ≤3%

Appearance of Molybdenum discs/circular plates:

It has a silver-gray metallic luster. According to the width and thickness provided by the user, the surface can be produced smoothly and evenly without defects

such as heavy skin, delamination, cracks, cracks and impurities.

Processing technology: cold rolling.

The surface state can be divided into: cold rolled surface, alkali washed surface.

Packaging of Molybdenum discs/circular plate :

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

More of Molybdenum discs/circular plate:

Our company adopts a proprietary production process, and the hot and cold-rolled high-temperature molybdenum sheets, sheets and strip products produced by rolling increase the crystallization temperature of molybdenum by 500 ° C to 700 ° C.

Use with higher temperature performance. The need for a heat shield material that meets the vacuum furnace operating temperature of 1850 ° C.

Applicationof Molybdenum discs/circular plate:

Used in electronics, aviation, aerospace, electric light source, heating element in vacuum furnace, heat shield, molybdenum boat, molybdenum crucible, etc.

here

for

price