- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

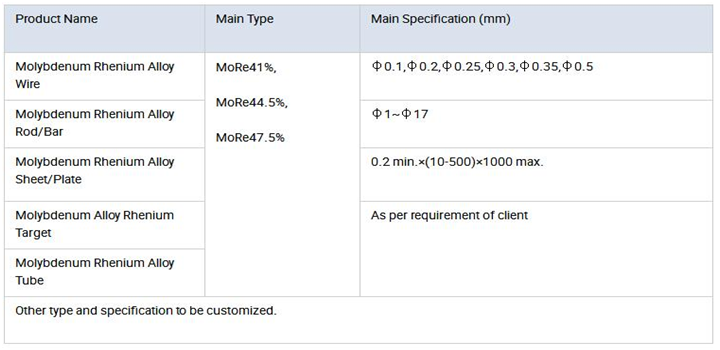

Molybdenum-Rhenium Alloy Sheet

Type: MoRe41%, MoRe44.5%, MoRe47.5%

Thickness: 0.2mm~10mm

Width: 10-500mm

Length: 1000mm max

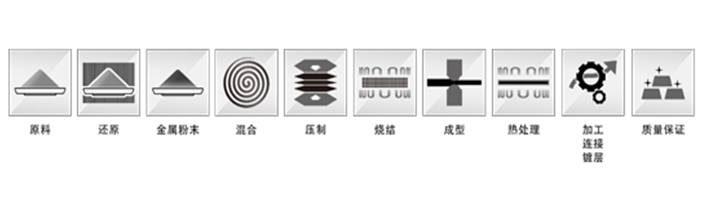

Shanghai Metal Corporation is a leading molybdenum-rhenium alloy sheet manufacturer and supplier.

Mo-Re alloy is Molybdenum Alloyed with 41% or 47.5% of Rhenium (nominal content of Rhenium is 50%), which has good ductility, weld ability, formability, and strength. Mo-Re alloy keeps high ductile even after used in high temperature. Molybdenum Rhenium alloy has excellent strength and plasticity in high temperature, which can be used as basis materials making structure parts, heater, special parts for aerospace, atomic energy, superalloys, magnetron sputtering targets, high temperature thermal field and so on.

Generally immediately available in most volumes, we are available as bar, ingot, ribbon, wire, shot, sheet, and foil. Ultra high purity and high purity forms also include metal powder, submicron powder and nanoscale, targets for thin film deposition, and pellets for chemical vapor deposition (CVD) and physical vapor deposition (PVD) applications. We produce to many standard grades when applicable. Typical and custom packaging is available. Primary applications include bearing assembly, ballast, casting, step soldering, and radiation shielding.We also can provide molybdenum-rhenium alloy wire.

If you want to know more about our copper products products or molybdenum-rhenium alloy sheet price please feel free to contact us, we will reply you within 24 hours.

-

1) Grade: MoRe41%, MoRe44.5%, MoRe47.5%

2) Thickness: 0.2mm~10mm

3) Width: 10-500mm

4) Length: 1000mm max

-

-

-

1) Excellent electric performance

2) Longer working life

3) More endurance under bad conditions

4) excellent high-temp strength and plasticity

5) High reliability couplings

-

-

the molybdenum rhenium alloys have excellent high-temp strength and plasticity, they could be used as base materials for making structure parts, heater and special parts for aerospace, atomic energy, super alloys, magnetron sputtering targets etc. molybdenum rhenium bar/rod mainly used to made electrode and welding electrode, nuclear, and space applications.

-

1) Hardness

2) Tensile Strength

3) Elongation

4) Metal-Detector

5) Conductivity

6) Chemical Content

-

Technical Information of Molybdenum-Rhenium Alloy Sheet:

This is a kind of alloy formed by adding 4 1% to 47.5 % bismuth in molybdenum. After adding bismuth, the ductility, weldability and formability of the alloy can be greatly improved. Even after high temperature use, the molybdenum-niobium alloy can still Maintain good ductility.

Packaging of Molybdenum-Rhenium Alloy Sheet:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Advantage of Molybdenum-Rhenium Alloy Sheet:

Excellent electric performance

Longer working life

More endurance under bad conditions

Application of Molybdenum-Rhenium Alloy Sheet:

Common Use: when adding rhenium into molybdenum ,the molybdenum rhenium alloys have excellent high-temp strength and plasticity, they could be used as base materials for making structure parts, heater and special parts for aerospace, atomic energy, super alloys, magnetron sputtering targets etc. molybdenum rhenium bar/rod mainly used to made electrode and welding electrode, nuclear, and space applications.

here

for

price